TEL: 1-608-238-6001 Email: greg@electricship.com

|

|

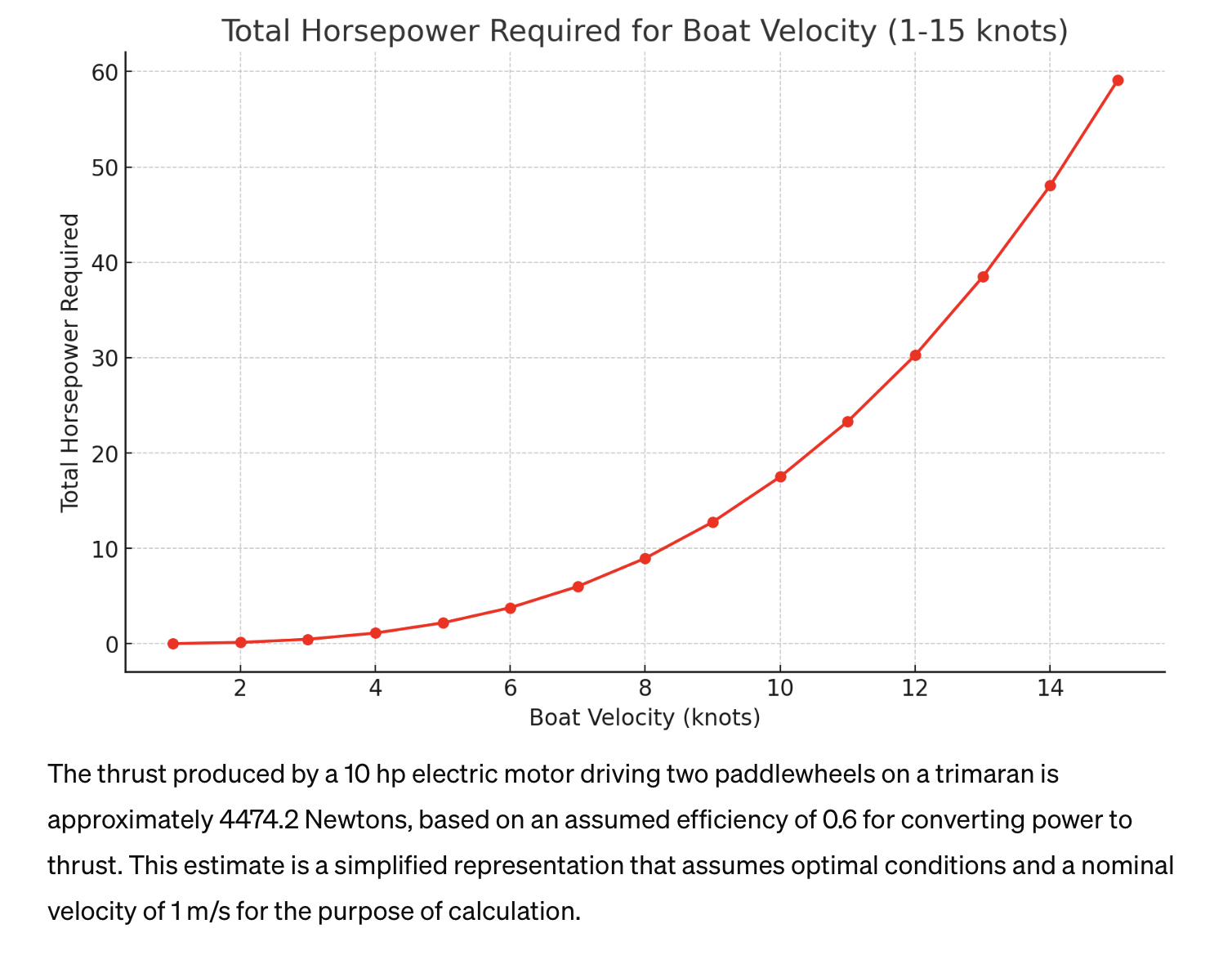

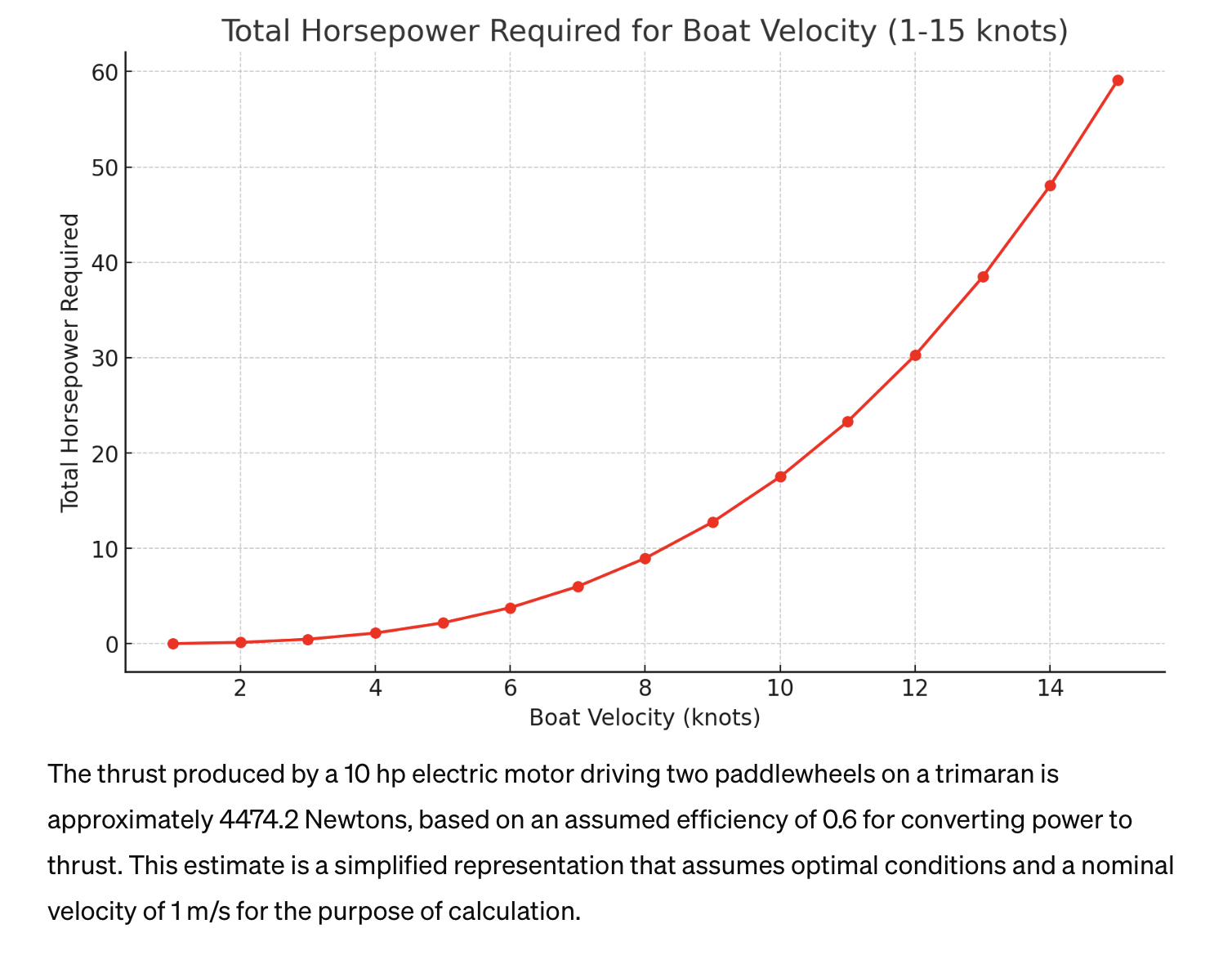

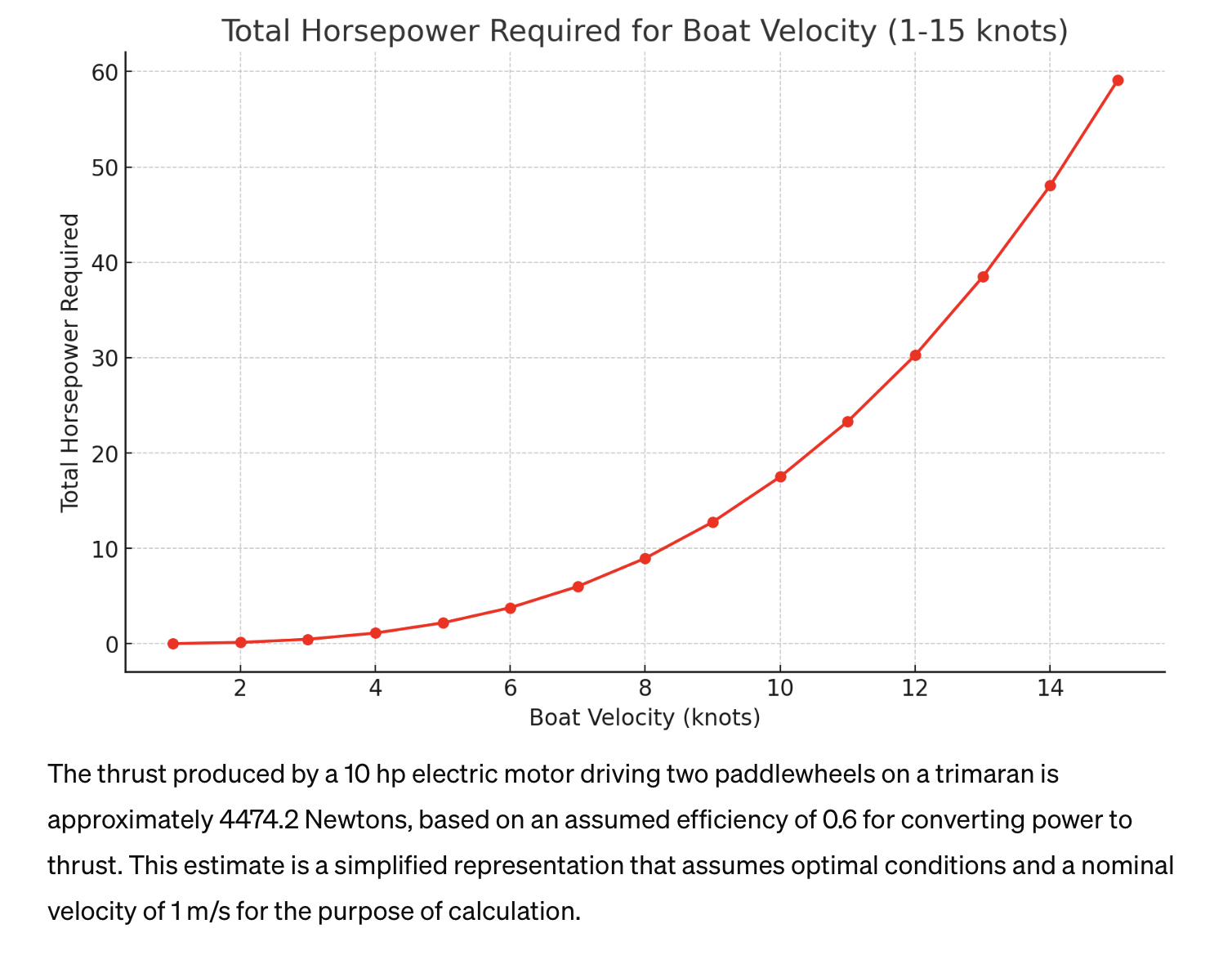

Paddlewheel Power Requirements Calculate and chart the amount of thrust for a 10 hp electric motor drive paddlewheel with the following characteristics: 2 separate paddlewheels which have a blade measure of 6 ft wide, by 4 feet in height, and there are 8 total blades. blade emersion in the water is 3 feet. The type of craft to be propelled is a trimaran, with a wetted surface pontoons that measure 60 feet in length, 2 feet in width, and 4 feet in height. This is a freshwater craft. The vessel weight is 25,000 pounds. Calculate and chart total HP required for each knot of boat velocity from 1-15 knots.To calculate and chart the thrust produced by a 10 hp electric motor driving two paddlewheels on a trimaran, and then to chart the total horsepower required for each knot of boat velocity from 1 to 15 knots, we will follow these steps:1. Thrust from the Paddlewheel: We'll start by estimating the thrust generated by the paddlewheels driven by a 10 hp electric motor. The thrust will depend on the motor's power, the efficiency of the paddlewheel system, and the specifics of the paddlewheel design (blade measurements and emersion).2. Total Horsepower Required per Velocity: To calculate the horsepower required for each knot of velocity (from 1 to 15 knots), we'll use a simplified resistance formula that considers the craft's size, weight, and the characteristics of the paddlewheels. We'll then plot this against boat velocity to visualize the power requirements across the speed range.Assumptions and Simplifications:• Efficiency of the Paddlewheel System: We'll assume a typical efficiency for the paddlewheel system. This efficiency accounts for losses in converting power to thrust and the hydrodynamic characteristics of the paddlewheels.• Resistance Calculation: The resistance of the trimaran will be estimated using a simplified formula that captures the essence of hydrodynamic drag, which increases with the square of the velocity.• Freshwater Conditions: Since the craft operates in freshwater, we'll use the relevant density for freshwater.Let's proceed with the calculations, starting with the thrust estimation for the paddlewheels, followed by the horsepower required for velocities from 1 to 15 knots.The thrust produced by a 10 hp electric motor driving two paddlewheels on a trimaran is approximately 4474.2 Newtons, based on an assumed efficiency of 0.6 for converting power to thrust. This estimate is a simplified representation that assumes optimal conditions and a nominal velocity of 1 m/s for the purpose of calculation.The chart above illustrates the total horsepower required for the boat to achieve velocities ranging from 1 to 15 knots. The required horsepower increases significantly with speed, reflecting the non-linear relationship between velocity and the power needed to overcome hydrodynamic resistance. At lower speeds (1-5 knots), the increase in required horsepower is relatively modest. However, as the speed increases beyond this range, the horsepower required rises more steeply, highlighting the increased resistance encountered at higher velocities.For instance, to propel the boat at 1 knot requires approximately 0.02 horsepower, which is minimal. However, to achieve 8 knots, the vessel needs about 9 horsepower, and for 15 knots, the requirement jumps to approximately 59 horsepower. This demonstrates the significant increase in power needed to overcome the resistance at higher speeds and the challenges in designing efficient propulsion systems for higher-speed operations.This analysis provides valuable insights into the propulsion requirements for a trimaran with the specified characteristics and operating conditions. It highlights the importance of considering both the thrust generated by propulsion systems and the power requirements across a range of speeds when designing and operating such vessels.

|

|

Paddlewheel Power Requirements The type of craft to be propelled is a trimaran, with a wetted surface pontoons that measure 60 feet in length, 2 feet in width, and 4 feet in height. This is a freshwater craft. The vessel weight is 15,000 pounds. Now calculate the immersion depth of the pontoons and the amount of horsepower needed to drive the boat 8 knots with 2 separate paddlewheels which have a blade measure of 6 ft wide, by 4 feet in height, and there are 8 total blades. Then compare that to two screw propeller outboards with a diameter of the screw of 16 inches. Calculate the horsepower needed for each method of propulsion.To approach this task, we will first calculate the immersion depth of the pontoons for the trimaran, which will give us an understanding of how much of the pontoons are submerged and therefore the displacement of the vessel. Next, we will calculate the horsepower needed to drive the boat at 8 knots using both the paddlewheel and screw propeller propulsion methods.Calculating Immersion Depth of the PontoonsThe trimaran's pontoon dimensions are given, and we know the total weight of the vessel. Using the principle of buoyancy (Archimedes' principle), the weight of the water displaced by the pontoons will equal the weight of the vessel.Given:• Vessel weight = 15,000 pounds• Pontoon dimensions: Length = 60 feet, Width = 2 feet, Height = 4 feet• Density of freshwater = 62.4 pounds per cubic footWe'll start by calculating the immersion depth of the pontoons.Horsepower Needed for Paddlewheel PropulsionAfter determining the immersion depth, we'll calculate the horsepower needed to drive the boat at 8 knots using paddlewheels. For this, we'll consider the efficiency of paddlewheel propulsion and the resistance encountered by the vessel at this speed.Given:• Speed = 8 knots (convert to feet per second)• Paddlewheel blade dimensions: Width = 6 feet, Height = 4 feet, Total blades = 8• Efficiency factors and resistances will be estimated.Horsepower Needed for Screw Propeller PropulsionFor the screw propeller propulsion, we'll calculate the horsepower needed based on the characteristics of the propellers and the same speed. We consider the diameter of the screw (propeller) and the typical efficiency of such propulsion systems.Given:• Diameter of the screw = 16 inches (convert to feet)• Speed = 8 knotsLet's start with the calculations for the immersion depth of the pontoons and then proceed to calculate the horsepower needed for both propulsion methods.The calculated immersion depth of the pontoons is approximately 1.00 feet. This means that when the trimaran is stationary or moving, the pontoons will be submerged about 1 foot into the water to support the weight of the vessel.Next, we will calculate the horsepower needed to drive the boat at 8 knots using two separate methods of propulsion: paddlewheels and screw propellers. Calculating Horsepower for Paddlewheel PropulsionThe horsepower needed for paddlewheel propulsion can be estimated based on the resistance the vessel faces at 8 knots and the efficiency of the paddlewheel system. The total resistance encountered by the vessel can be approximated using empirical formulas, which take into account the vessel's speed, dimensions, and the water's properties. However, for simplification, we will use a general approach focusing on the speed and dimensions given, along with typical efficiencies for paddlewheel systems.Calculating Horsepower for Screw Propeller PropulsionTo calculate the horsepower needed for screw propeller propulsion, we use similar principles, focusing on the hydrodynamic efficiency of the propellers and the vessel's speed. The efficiency of propeller systems varies based on the design and operation conditions, but we will use average efficiencies for our calculations.Let's proceed with the calculations for the horsepower needed for both propulsion methods, starting with the paddlewheel propulsion, followed by the screw propeller propulsion.To propel the trimaran at 8 knots using paddlewheel propulsion, approximately 4.30 horsepower is required. In comparison, for screw propeller propulsion, about 3.59 horsepower is needed. These calculations are based on simplified models and assumptions about efficiency and resistance but provide a comparative analysis of the two propulsion methods under the specified conditions.ConclusionThe screw propeller method requires less horsepower to achieve the same speed compared to the paddlewheel method for this particular trimaran design. This difference can be attributed to the higher efficiency typically associated with screw propeller systems in converting engine power to thrust, especially in open water conditions. Screw propellers generally provide better performance at higher speeds and are more efficient in terms of energy conversion, which is reflected in the lower horsepower requirement.It's important to note that the actual power required could vary based on more detailed hydrodynamic analyses and specific design considerations for both the paddlewheels and the screw propellers. However, this comparison highlights the general principle that screw propellers are often more efficient for high-speed watercraft, while paddlewheels might offer advantages in specific applications, such as shallow water navigation or where low-speed maneuverability is crucial. |

|

|

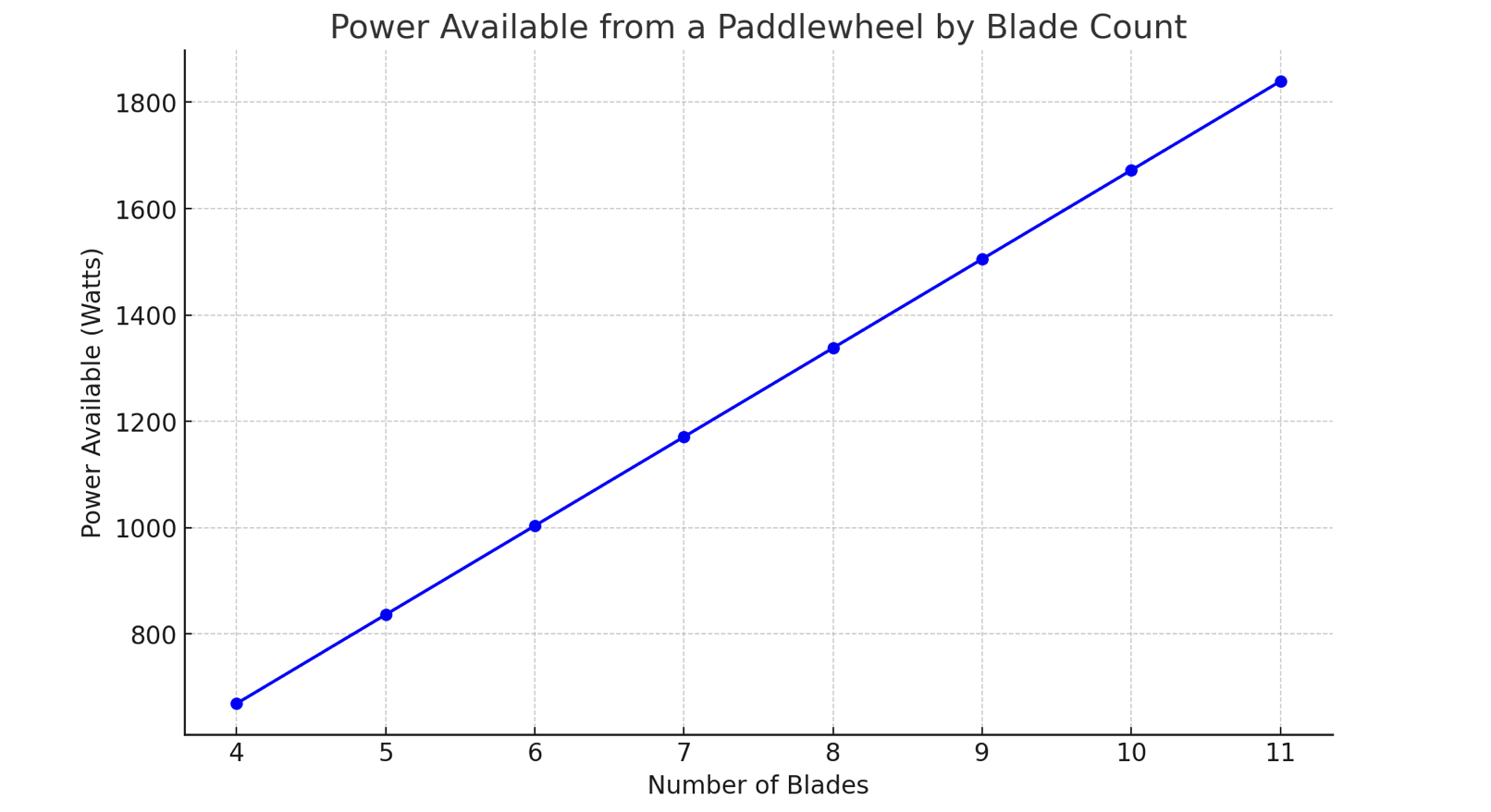

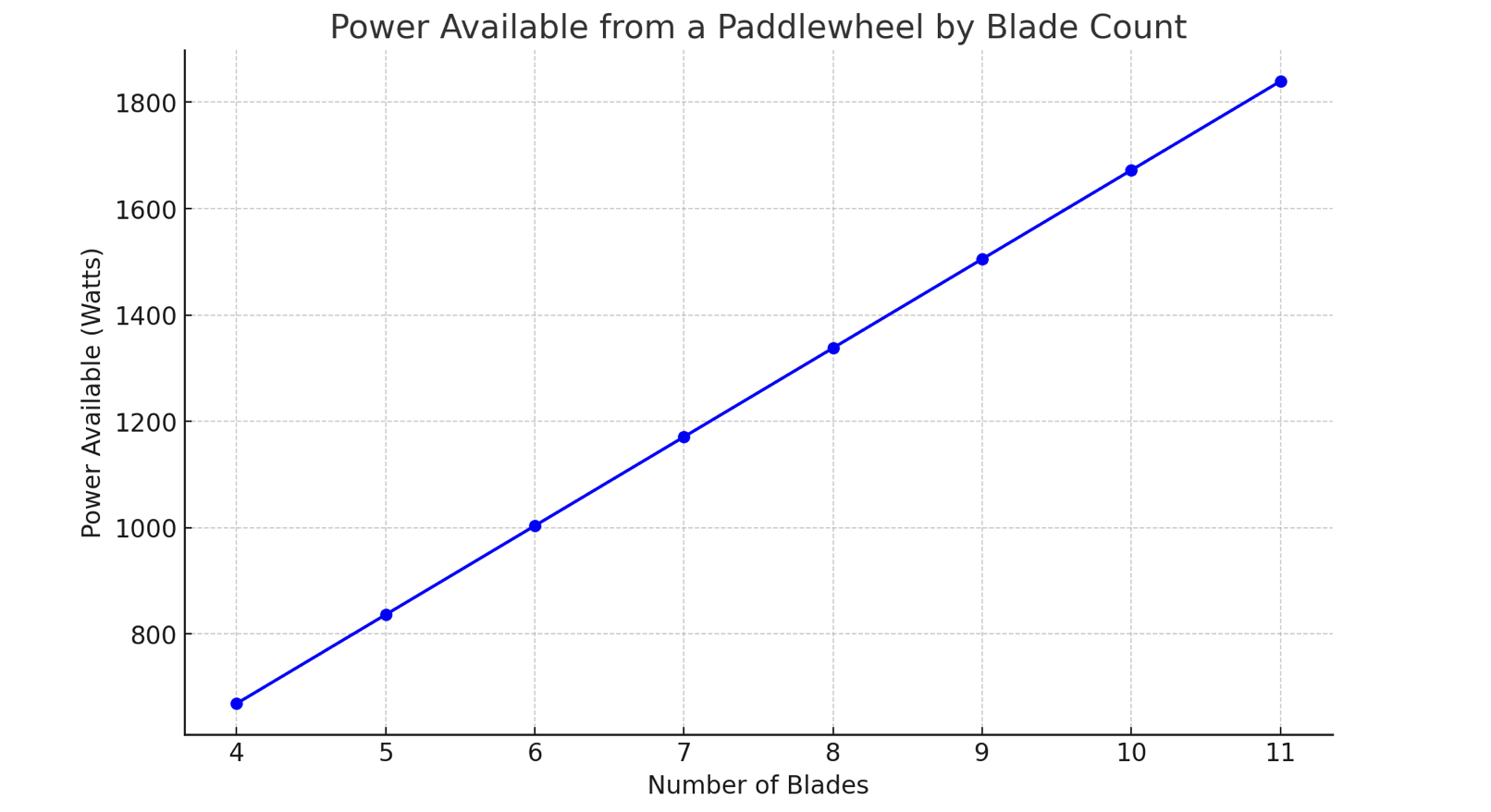

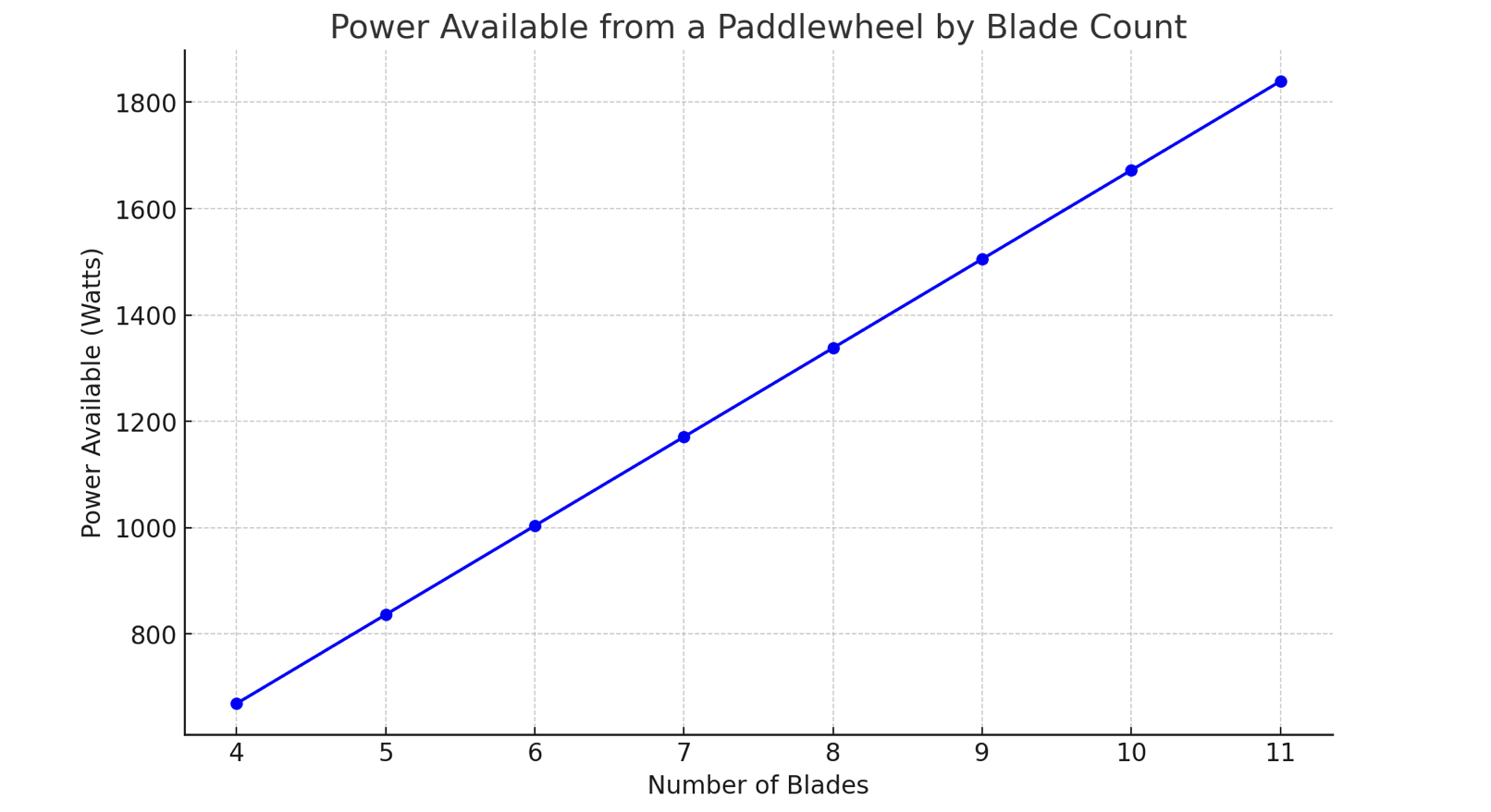

Paddlewheel Propulsion vs. Screw Propeller Discuss the benefits of a paddlewheel propulsion vs screw propeller, including efficiencies and charting the power available for a 4 ft wide by 3 foot height paddlewheel blade comparing total blades of 4, 5, 6, 7, 8, 9, 10, and 11 total blades.Paddlewheel propulsion and screw propeller systems are two methods used to propel vessels through water. Each system has its unique advantages and efficiencies, which can significantly affect the performance and applicability of different types of watercraft. In this article, we will explore the benefits of paddlewheel propulsion compared to screw propeller systems, focusing on their efficiencies. Additionally, we will present charts that illustrate the power available from a paddlewheel with a blade size of 4 feet in width by 3 feet in height, comparing the impact of varying the total number of blades from 4 to 11.Paddlewheel Propulsion vs. Screw Propeller: An OverviewPaddlewheel Propulsion:Paddlewheel propulsion, one of the oldest forms of propelling boats, uses large wheels with paddles attached around their circumference. These wheels rotate, pushing against the water to propel the vessel forward. This method is particularly effective in shallow waters and where maneuverability at low speeds is crucial.Screw Propeller:The screw propeller, or simply propeller, is a much more common propulsion system in modern watercraft. It consists of rotating blades that operate similarly to a screw, moving water in the opposite direction to propel the boat forward. Propellers are known for their efficiency at higher speeds and deeper waters.Efficiencies and BenefitsPaddlewheel Propulsion:• Shallow Water Navigation: Paddlewheels are more efficient in shallow waters because they are less likely to get damaged from the seabed or debris.• Maneuverability: At lower speeds, paddlewheels provide better maneuverability, making them ideal for riverboats and ferries.• Historical and Aesthetic Value: Paddlewheelers have a unique charm and are often used in tourist attractions for their nostalgic value.Screw Propeller:• High-Speed Efficiency: Screw propellers offer better performance and efficiency at higher speeds, making them suitable for modern shipping, naval vessels, and recreational boats.• Versatility: They can be used in various water conditions, including open sea and deep waters, without the risk of damage from underwater obstacles.• Design Flexibility: Propellers can be designed with different numbers of blades and shapes to optimize performance for specific conditions.Power Available from a Paddlewheel: A Comparative AnalysisTo understand the impact of the number of blades on the performance of a paddlewheel, let's analyze the power available from a paddlewheel with a blade size of 4 ft wide by 3 ft height. The total number of blades will vary from 4 to 11. The power generated by a paddlewheel can be influenced by several factors, including the water's resistance against the paddles, the speed of rotation, and the efficiency of energy conversion.Assumptions for Calculation:• Water density is assumed constant.• The paddlewheel operates at an optimal speed for each blade configuration.• The efficiency of energy conversion is considered constant across different blade counts.Let's calculate and chart the estimated power available for each configuration, taking into account the theoretical efficiency and performance characteristics of paddlewheels with varying numbers of blades.The chart above illustrates the power available from a paddlewheel as the number of blades increases from 4 to 11. Each point on the graph represents the calculated power available for a paddlewheel with a specific number of blades, under the assumptions of constant water density, optimal rotational speed, and a fixed efficiency of energy conversion.From the chart, we observe a trend indicating that the power available from the paddlewheel increases as the number of blades increases. This increase can be attributed to the greater submerged area of the blades at any given time, which allows for more water to be pushed per rotation, effectively increasing the power output.However, it's important to note that while adding more blades can increase power, there are practical limits to this approach. The efficiency of energy conversion might decrease due to factors such as increased drag and turbulence with too many blades. Moreover, there are mechanical and structural considerations, such as the increased weight and complexity of the paddlewheel.In conclusion, when comparing paddlewheel propulsion to screw propellers, it's evident that each system has distinct advantages tailored to specific scenarios. Paddlewheels excel in shallow waters and low-speed maneuverability, offering unique aesthetic and historical values. On the other hand, screw propellers provide superior efficiency at high speeds and are more versatile in various water conditions.The analysis of power available from a paddlewheel with varying blade counts underscores the importance of design optimization tailored to specific operational requirements. Understanding these dynamics can help in designing more efficient and suitable propulsion systems for different types of watercraft.

|

|

Trimaran Paddlewheel The type of craft to be propelled is a trimaran, with a wetted surface pontoons that measure 60 feet in length, 2 feet in width, and 4 feet in height. This is a freshwater craft. The vessel weight is 15,000 pounds. Now calculate the immersion depth of the pontoons and the amount of horsepower needed to drive the boat 8 knots with 2 separate paddlewheels which have a blade measure of 6 ft wide, by 4 feet in height, and there are 8 total blades. Then compare that to two screw propeller outboards with a diameter of the screw of 16 inches. Calculate the horsepower needed for each method of propulsion.To approach this task, we will first calculate the immersion depth of the pontoons for the trimaran, which will give us an understanding of how much of the pontoons are submerged and therefore the displacement of the vessel. Next, we will calculate the horsepower needed to drive the boat at 8 knots using both the paddlewheel and screw propeller propulsion methods.Calculating Immersion Depth of the PontoonsThe trimaran's pontoon dimensions are given, and we know the total weight of the vessel. Using the principle of buoyancy (Archimedes' principle), the weight of the water displaced by the pontoons will equal the weight of the vessel.Given:• Vessel weight = 15,000 pounds• Pontoon dimensions: Length = 60 feet, Width = 2 feet, Height = 4 feet• Density of freshwater = 62.4 pounds per cubic footWe'll start by calculating the immersion depth of the pontoons.Horsepower Needed for Paddlewheel PropulsionAfter determining the immersion depth, we'll calculate the horsepower needed to drive the boat at 8 knots using paddlewheels. For this, we'll consider the efficiency of paddlewheel propulsion and the resistance encountered by the vessel at this speed.Given:• Speed = 8 knots (convert to feet per second)• Paddlewheel blade dimensions: Width = 6 feet, Height = 4 feet, Total blades = 8• Efficiency factors and resistances will be estimated.Horsepower Needed for Screw Propeller PropulsionFor the screw propeller propulsion, we'll calculate the horsepower needed based on the characteristics of the propellers and the same speed. We consider the diameter of the screw (propeller) and the typical efficiency of such propulsion systems.Given:• Diameter of the screw = 16 inches (convert to feet)• Speed = 8 knotsLet's start with the calculations for the immersion depth of the pontoons and then proceed to calculate the horsepower needed for both propulsion methods.The calculated immersion depth of the pontoons is approximately 1.00 feet. This means that when the trimaran is stationary or moving, the pontoons will be submerged about 1 foot into the water to support the weight of the vessel.Next, we will calculate the horsepower needed to drive the boat at 8 knots using two separate methods of propulsion: paddlewheels and screw propellers. Calculating Horsepower for Paddlewheel PropulsionThe horsepower needed for paddlewheel propulsion can be estimated based on the resistance the vessel faces at 8 knots and the efficiency of the paddlewheel system. The total resistance encountered by the vessel can be approximated using empirical formulas, which take into account the vessel's speed, dimensions, and the water's properties. However, for simplification, we will use a general approach focusing on the speed and dimensions given, along with typical efficiencies for paddlewheel systems.Calculating Horsepower for Screw Propeller PropulsionTo calculate the horsepower needed for screw propeller propulsion, we use similar principles, focusing on the hydrodynamic efficiency of the propellers and the vessel's speed. The efficiency of propeller systems varies based on the design and operation conditions, but we will use average efficiencies for our calculations.Let's proceed with the calculations for the horsepower needed for both propulsion methods, starting with the paddlewheel propulsion, followed by the screw propeller propulsion.To propel the trimaran at 8 knots using paddlewheel propulsion, approximately 4.30 horsepower is required. In comparison, for screw propeller propulsion, about 3.59 horsepower is needed. These calculations are based on simplified models and assumptions about efficiency and resistance but provide a comparative analysis of the two propulsion methods under the specified conditions.ConclusionThe screw propeller method requires less horsepower to achieve the same speed compared to the paddlewheel method for this particular trimaran design. This difference can be attributed to the higher efficiency typically associated with screw propeller systems in converting engine power to thrust, especially in open water conditions. Screw propellers generally provide better performance at higher speeds and are more efficient in terms of energy conversion, which is reflected in the lower horsepower requirement.It's important to note that the actual power required could vary based on more detailed hydrodynamic analyses and specific design considerations for both the paddlewheels and the screw propellers. However, this comparison highlights the general principle that screw propellers are often more efficient for high-speed watercraft, while paddlewheels might offer advantages in specific applications, such as shallow water navigation or where low-speed maneuverability is crucial.

|

|

Paddlewheel vs. Screw Propeller At speeds of less than 10 knots, the efficiency comparison between paddle wheel propulsion and propeller propulsion for a catamaran can shift somewhat due to the specific operating characteristics of each propulsion method. Let’s break down the factors affecting efficiency at these lower speeds:1. Propeller Propulsion at Low Speeds (< 10 knots)• Hydrodynamic Efficiency: At low speeds, propellers can be less efficient due to their design, which is often optimized for higher speeds. The slower rotation of the propeller blades at low speeds may lead to less efficient thrust generation, as the angle of attack on the blades may not be optimal.• Cavitation Risk: At very low speeds, cavitation is less of an issue, but the propeller might still operate in a suboptimal flow regime, leading to increased drag and reduced thrust efficiency.• Maneuverability: Propellers may provide less precise maneuvering at low speeds, particularly in conditions where slow, careful movement is necessary, such as docking or navigating tight spaces.2. Paddle Wheel Propulsion at Low Speeds (< 10 knots)• Hydrodynamic Efficiency: Paddle wheels can be more efficient at low speeds because they are designed to push water directly using large paddles, which can be effective at transferring power to the water at these speeds. The paddles engage the water more completely, providing consistent thrust even at lower rotations.• Mechanical Simplicity: At low speeds, the mechanical losses in paddle wheel systems are less significant compared to their operation at higher speeds. The direct engagement of the paddles with the water means that more of the engine’s power is converted into thrust.• Shallow Water Operation: Paddle wheels excel in shallow water conditions, which can be a factor at low speeds, especially for catamarans operating near shorelines or in rivers. The risk of striking underwater obstacles with a propeller is reduced with paddle wheels.3. Efficiency Consideration at < 10 knots• Energy Conversion: At low speeds, the energy conversion efficiency of paddle wheels can approach or even surpass that of propellers, especially if the propeller is not optimized for low-speed operation. The ability of paddle wheels to maintain effective thrust without the need for high rotational speeds can make them more energy-efficient in certain low-speed conditions.• Wave Resistance and Drag: While paddle wheels generally create more drag at higher speeds, this effect is less pronounced at speeds below 10 knots. The increase in drag from the paddle wheels may be offset by the greater efficiency in thrust generation at these speeds.• Operational Context: The specific conditions under which the catamaran is operating can also play a role. For instance, if the catamaran is frequently operating in shallow or confined waters where low-speed maneuverability is crucial, paddle wheels might offer an efficiency advantage over propellers.Conclusion:At speeds of less than 10 knots, paddle wheel propulsion can be more efficient than propeller propulsion, especially for specific low-speed applications such as shallow water navigation, precise maneuvering, or when the propulsion system is not optimized for low speeds. Paddle wheels can offer better energy conversion efficiency and more effective thrust generation in these conditions, making them a viable option for catamarans operating at slow speeds.However, the overall choice depends on the specific operational requirements, including the typical operating environment (e.g., shallow water vs. open sea), maneuverability needs, and whether the catamaran needs to occasionally exceed these speeds, where propellers would regain their efficiency advantage. |

| CONTACT TEL: +1-608-238-6001 Email: greg@electricship.com | AMP | PDF | Electric Ship is a division of Infinity Turbine LLC |