PDF Publication Title:

Text from PDF Page: 011

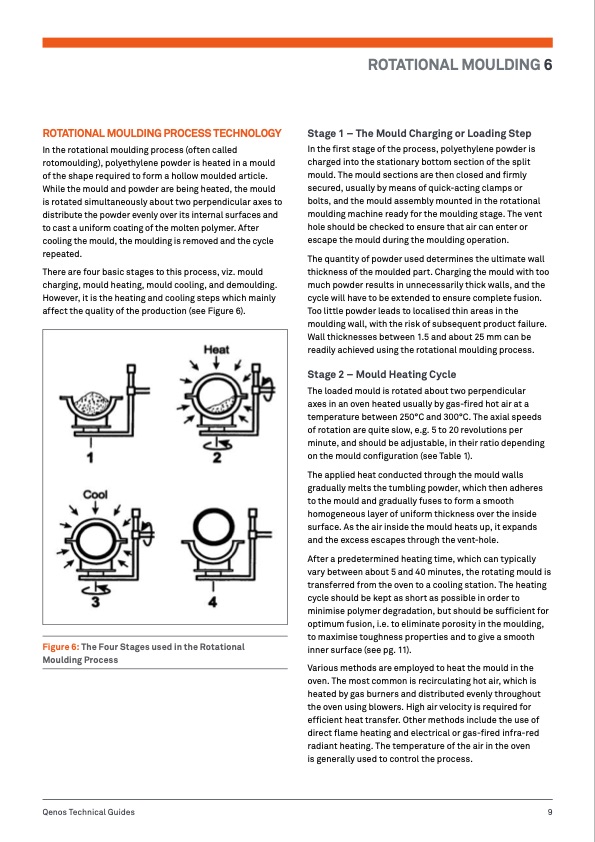

ROTATIONAL MOULDING PROCESS TECHNOLOGY In the rotational moulding process (often called rotomoulding), polyethylene powder is heated in a mould of the shape required to form a hollow moulded article. While the mould and powder are being heated, the mould is rotated simultaneously about two perpendicular axes to distribute the powder evenly over its internal surfaces and to cast a uniform coating of the molten polymer. After cooling the mould, the moulding is removed and the cycle repeated. There are four basic stages to this process, viz. mould charging, mould heating, mould cooling, and demoulding. However, it is the heating and cooling steps which mainly affect the quality of the production (see Figure 6). ROTATIONAL MOULDING 6 Stage 1 – The Mould Charging or Loading Step In the first stage of the process, polyethylene powder is charged into the stationary bottom section of the split mould. The mould sections are then closed and firmly secured, usually by means of quick-acting clamps or bolts, and the mould assembly mounted in the rotational moulding machine ready for the moulding stage. The vent hole should be checked to ensure that air can enter or escape the mould during the moulding operation. The quantity of powder used determines the ultimate wall thickness of the moulded part. Charging the mould with too much powder results in unnecessarily thick walls, and the cycle will have to be extended to ensure complete fusion. Too little powder leads to localised thin areas in the moulding wall, with the risk of subsequent product failure. Wall thicknesses between 1.5 and about 25 mm can be readily achieved using the rotational moulding process. Stage 2 – Mould Heating Cycle The loaded mould is rotated about two perpendicular axes in an oven heated usually by gas-fired hot air at a temperature between 250°C and 300°C. The axial speeds of rotation are quite slow, e.g. 5 to 20 revolutions per minute, and should be adjustable, in their ratio depending on the mould configuration (see Table 1). The applied heat conducted through the mould walls gradually melts the tumbling powder, which then adheres to the mould and gradually fuses to form a smooth homogeneous layer of uniform thickness over the inside surface. As the air inside the mould heats up, it expands and the excess escapes through the vent-hole. After a predetermined heating time, which can typically vary between about 5 and 40 minutes, the rotating mould is transferred from the oven to a cooling station. The heating cycle should be kept as short as possible in order to minimise polymer degradation, but should be sufficient for optimum fusion, i.e. to eliminate porosity in the moulding, to maximise toughness properties and to give a smooth inner surface (see pg. 11). Various methods are employed to heat the mould in the oven. The most common is recirculating hot air, which is heated by gas burners and distributed evenly throughout the oven using blowers. High air velocity is required for efficient heat transfer. Other methods include the use of direct flame heating and electrical or gas-fired infra-red radiant heating. The temperature of the air in the oven is generally used to control the process. Figure 6: The Four Stages used in the Rotational Moulding Process Qenos Technical Guides 9PDF Image | ROTATIONAL MOULDING Guide

PDF Search Title:

ROTATIONAL MOULDING GuideOriginal File Name Searched:

TG6Roto.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |