PDF Publication Title:

Text from PDF Page: 010

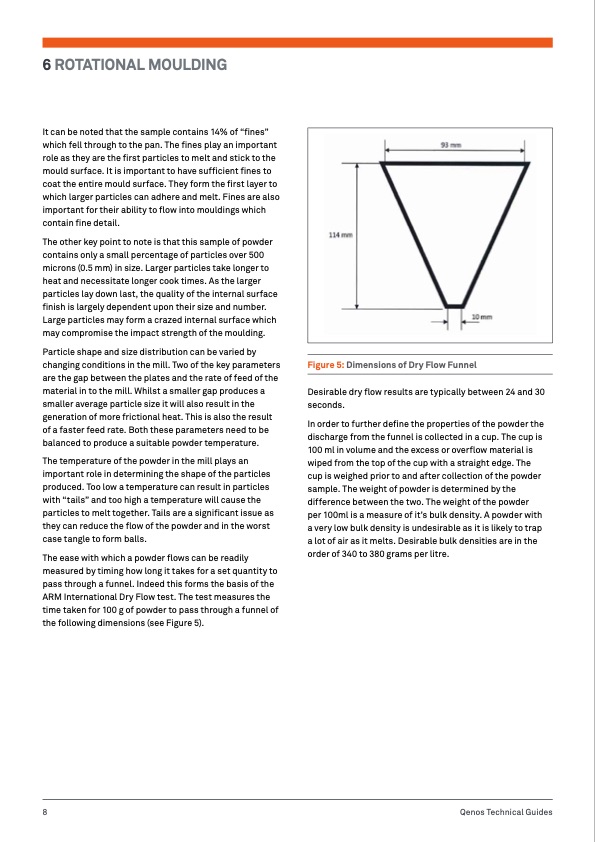

6 ROTATIONAL MOULDING It can be noted that the sample contains 14% of “fines” which fell through to the pan. The fines play an important role as they are the first particles to melt and stick to the mould surface. It is important to have sufficient fines to coat the entire mould surface. They form the first layer to which larger particles can adhere and melt. Fines are also important for their ability to flow into mouldings which contain fine detail. The other key point to note is that this sample of powder contains only a small percentage of particles over 500 microns (0.5 mm) in size. Larger particles take longer to heat and necessitate longer cook times. As the larger particles lay down last, the quality of the internal surface finish is largely dependent upon their size and number. Large particles may form a crazed internal surface which may compromise the impact strength of the moulding. Particle shape and size distribution can be varied by changing conditions in the mill. Two of the key parameters are the gap between the plates and the rate of feed of the material in to the mill. Whilst a smaller gap produces a smaller average particle size it will also result in the generation of more frictional heat. This is also the result of a faster feed rate. Both these parameters need to be balanced to produce a suitable powder temperature. The temperature of the powder in the mill plays an important role in determining the shape of the particles produced. Too low a temperature can result in particles with “tails” and too high a temperature will cause the particles to melt together. Tails are a significant issue as they can reduce the flow of the powder and in the worst case tangle to form balls. The ease with which a powder flows can be readily measured by timing how long it takes for a set quantity to pass through a funnel. Indeed this forms the basis of the ARM International Dry Flow test. The test measures the time taken for 100 g of powder to pass through a funnel of the following dimensions (see Figure 5). Figure 5: Dimensions of Dry Flow Funnel Desirable dry flow results are typically between 24 and 30 seconds. In order to further define the properties of the powder the discharge from the funnel is collected in a cup. The cup is 100 ml in volume and the excess or overflow material is wiped from the top of the cup with a straight edge. The cup is weighed prior to and after collection of the powder sample. The weight of powder is determined by the difference between the two. The weight of the powder per 100ml is a measure of it’s bulk density. A powder with a very low bulk density is undesirable as it is likely to trap a lot of air as it melts. Desirable bulk densities are in the order of 340 to 380 grams per litre. 8 Qenos Technical GuidesPDF Image | ROTATIONAL MOULDING Guide

PDF Search Title:

ROTATIONAL MOULDING GuideOriginal File Name Searched:

TG6Roto.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |