PDF Publication Title:

Text from PDF Page: 012

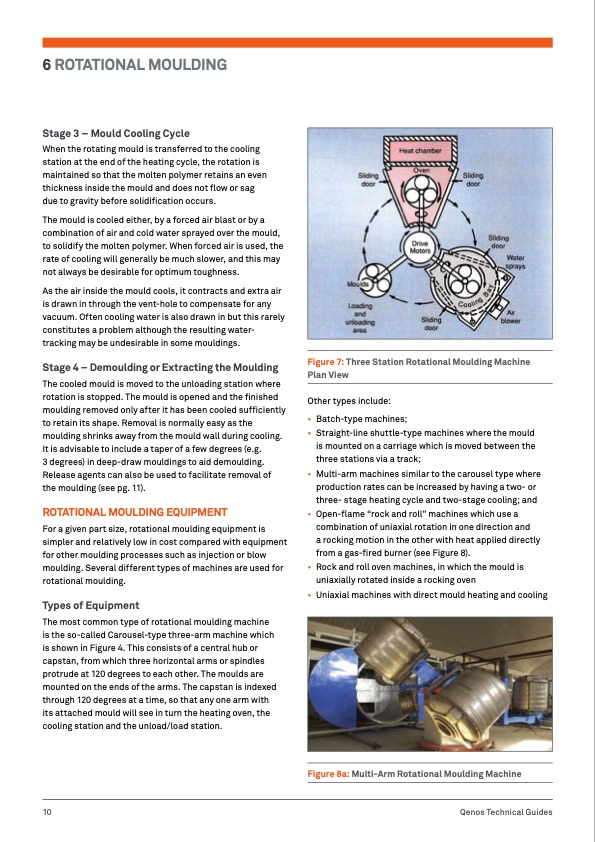

6 ROTATIONAL MOULDING Stage 3 – Mould Cooling Cycle When the rotating mould is transferred to the cooling station at the end of the heating cycle, the rotation is maintained so that the molten polymer retains an even thickness inside the mould and does not flow or sag due to gravity before solidification occurs. The mould is cooled either, by a forced air blast or by a combination of air and cold water sprayed over the mould, to solidify the molten polymer. When forced air is used, the rate of cooling will generally be much slower, and this may not always be desirable for optimum toughness. As the air inside the mould cools, it contracts and extra air is drawn in through the vent-hole to compensate for any vacuum. Often cooling water is also drawn in but this rarely constitutes a problem although the resulting water- tracking may be undesirable in some mouldings. Stage 4 – Demoulding or Extracting the Moulding The cooled mould is moved to the unloading station where rotation is stopped. The mould is opened and the finished moulding removed only after it has been cooled sufficiently to retain its shape. Removal is normally easy as the moulding shrinks away from the mould wall during cooling. It is advisable to include a taper of a few degrees (e.g. 3 degrees) in deep-draw mouldings to aid demoulding. Release agents can also be used to facilitate removal of the moulding (see pg. 11). ROTATIONAL MOULDING EQUIPMENT For a given part size, rotational moulding equipment is simpler and relatively low in cost compared with equipment for other moulding processes such as injection or blow moulding. Several different types of machines are used for rotational moulding. Types of Equipment The most common type of rotational moulding machine is the so-called Carousel-type three-arm machine which is shown in Figure 4. This consists of a central hub or capstan, from which three horizontal arms or spindles protrude at 120 degrees to each other. The moulds are mounted on the ends of the arms. The capstan is indexed through 120 degrees at a time, so that any one arm with its attached mould will see in turn the heating oven, the cooling station and the unload/load station. 10 Figure 7: Three Station Rotational Moulding Machine Plan View Other types include: • Batch-typemachines; • Straight-lineshuttle-typemachineswherethemould is mounted on a carriage which is moved between the three stations via a track; • Multi-armmachinessimilartothecarouseltypewhere production rates can be increased by having a two- or three- stage heating cycle and two-stage cooling; and • Open-flame “rock and roll” machines which use a combination of uniaxial rotation in one direction and a rocking motion in the other with heat applied directly from a gas-fired burner (see Figure 8). • Rock and roll oven machines, in which the mould is uniaxially rotated inside a rocking oven • Uniaxialmachineswithdirectmouldheatingandcooling Figure 8a: Multi-Arm Rotational Moulding Machine Qenos Technical GuidesPDF Image | ROTATIONAL MOULDING Guide

PDF Search Title:

ROTATIONAL MOULDING GuideOriginal File Name Searched:

TG6Roto.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |