PDF Publication Title:

Text from PDF Page: 022

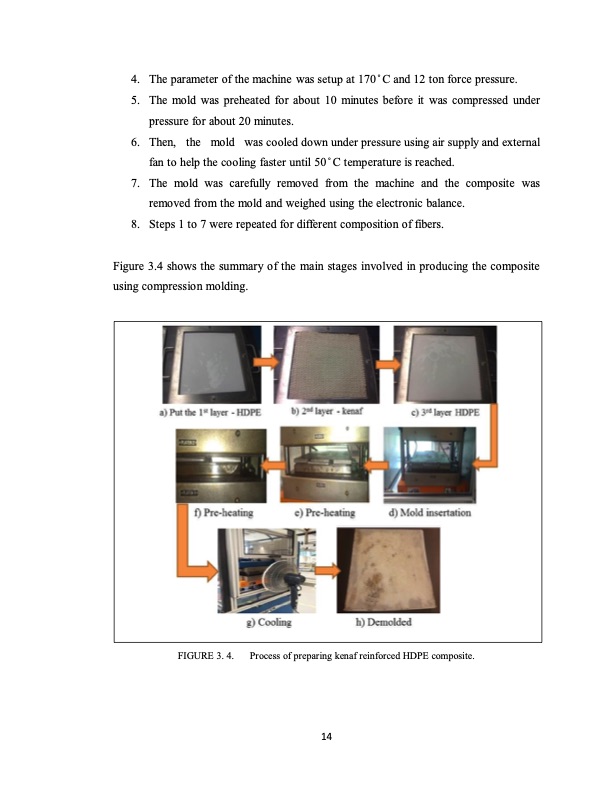

4. The parameter of the machine was setup t 1 nd 12 ton force pressure. 5. The mold was preheated for about 10 minutes before it was compressed under pressure for about 20 minutes. 6. Then, the mold was cooled down under pressure using ir supply nd extern l f n to help the cooling f ster until 5 temperature is reached. 7. The mold was carefully removed from the machine and the composite was removed from the mold and weighed using the electronic balance. 8. Steps 1 to 7 were repeated for different composition of fibers. Figure 3.4 shows the summary of the main stages involved in producing the composite using compression molding. FIGURE 3. 4. Process of preparing kenaf reinforced HDPE composite. 14PDF Image | Woven Kenaf Reinforced High Density Polyethylene HDPE

PDF Search Title:

Woven Kenaf Reinforced High Density Polyethylene HDPEOriginal File Name Searched:

Dissertation-14009.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |