PDF Publication Title:

Text from PDF Page: 008

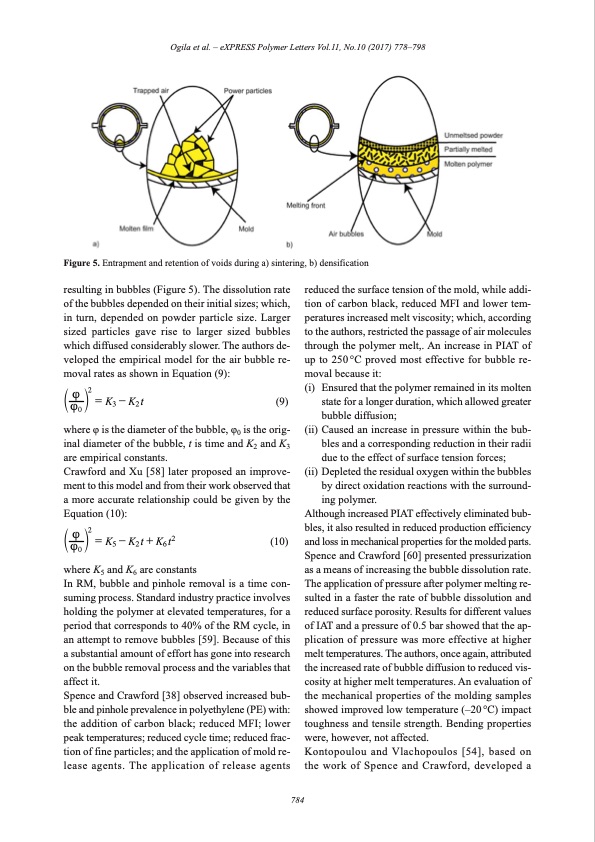

{2 T{0Y =K3-K2t (9) Ogila et al. – eXPRESS Polymer Letters Vol.11, No.10 (2017) 778–798 Figure 5. Entrapment and retention of voids during a) sintering, b) densification resulting in bubbles (Figure 5). The dissolution rate of the bubbles depended on their initial sizes; which, in turn, depended on powder particle size. Larger sized particles gave rise to larger sized bubbles which diffused considerably slower. The authors de- veloped the empirical model for the air bubble re- moval rates as shown in Equation (9): reduced the surface tension of the mold, while addi- tion of carbon black, reduced MFI and lower tem- peratures increased melt viscosity; which, according to the authors, restricted the passage of air molecules through the polymer melt,. An increase in PIAT of up to 250°C proved most effective for bubble re- moval because it: (i) Ensured that the polymer remained in its molten state for a longer duration, which allowed greater bubble diffusion; (ii) Caused an increase in pressure within the bub- bles and a corresponding reduction in their radii due to the effect of surface tension forces; (ii) Depleted the residual oxygen within the bubbles by direct oxidation reactions with the surround- ing polymer. Although increased PIAT effectively eliminated bub- bles, it also resulted in reduced production efficiency and loss in mechanical properties for the molded parts. Spence and Crawford [60] presented pressurization as a means of increasing the bubble dissolution rate. The application of pressure after polymer melting re- sulted in a faster the rate of bubble dissolution and reduced surface porosity. Results for different values of IAT and a pressure of 0.5 bar showed that the ap- plication of pressure was more effective at higher melt temperatures. The authors, once again, attributed the increased rate of bubble diffusion to reduced vis- cosity at higher melt temperatures. An evaluation of the mechanical properties of the molding samples showed improved low temperature (–20 °C) impact toughness and tensile strength. Bending properties were, however, not affected. Kontopoulou and Vlachopoulos [54], based on the work of Spence and Crawford, developed a where φ is the diameter of the bubble, φ0 is the orig- inal diameter of the bubble, t is time and K2 and K3 are empirical constants. Crawford and Xu [58] later proposed an improve- ment to this model and from their work observed that a more accurate relationship could be given by the Equation (10): {2 T{0Y =K5-K2t+K6t2 (10) where K5 and K6 are constants In RM, bubble and pinhole removal is a time con- suming process. Standard industry practice involves holding the polymer at elevated temperatures, for a period that corresponds to 40% of the RM cycle, in an attempt to remove bubbles [59]. Because of this a substantial amount of effort has gone into research on the bubble removal process and the variables that affect it. Spence and Crawford [38] observed increased bub- ble and pinhole prevalence in polyethylene (PE) with: the addition of carbon black; reduced MFI; lower peak temperatures; reduced cycle time; reduced frac- tion of fine particles; and the application of mold re- lease agents. The application of release agents 784PDF Image | Rotational molding: A review

PDF Search Title:

Rotational molding: A reviewOriginal File Name Searched:

Rotational_molding_A_review_of_the_models_and_mate.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |