PDF Publication Title:

Text from PDF Page: 007

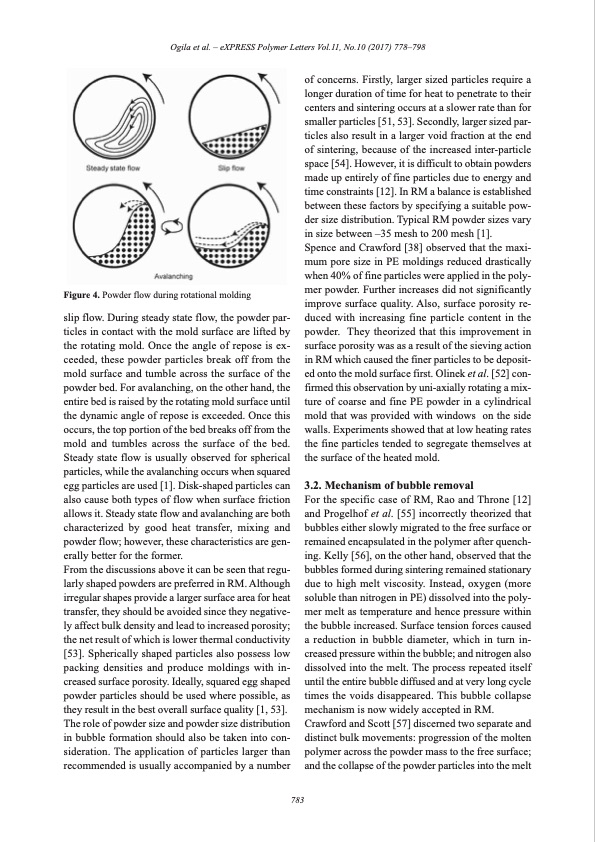

Ogila et al. – eXPRESS Polymer Letters Vol.11, No.10 (2017) 778–798 Figure 4. Powder flow during rotational molding slip flow. During steady state flow, the powder par- ticles in contact with the mold surface are lifted by the rotating mold. Once the angle of repose is ex- ceeded, these powder particles break off from the mold surface and tumble across the surface of the powder bed. For avalanching, on the other hand, the entire bed is raised by the rotating mold surface until the dynamic angle of repose is exceeded. Once this occurs, the top portion of the bed breaks off from the mold and tumbles across the surface of the bed. Steady state flow is usually observed for spherical particles, while the avalanching occurs when squared egg particles are used [1]. Disk-shaped particles can also cause both types of flow when surface friction allows it. Steady state flow and avalanching are both characterized by good heat transfer, mixing and powder flow; however, these characteristics are gen- erally better for the former. From the discussions above it can be seen that regu- larly shaped powders are preferred in RM. Although irregular shapes provide a larger surface area for heat transfer, they should be avoided since they negative- ly affect bulk density and lead to increased porosity; the net result of which is lower thermal conductivity [53]. Spherically shaped particles also possess low packing densities and produce moldings with in- creased surface porosity. Ideally, squared egg shaped powder particles should be used where possible, as they result in the best overall surface quality [1, 53]. The role of powder size and powder size distribution in bubble formation should also be taken into con- sideration. The application of particles larger than recommended is usually accompanied by a number of concerns. Firstly, larger sized particles require a longer duration of time for heat to penetrate to their centers and sintering occurs at a slower rate than for smaller particles [51, 53]. Secondly, larger sized par- ticles also result in a larger void fraction at the end of sintering, because of the increased inter-particle space [54]. However, it is difficult to obtain powders made up entirely of fine particles due to energy and time constraints [12]. In RM a balance is established between these factors by specifying a suitable pow- der size distribution. Typical RM powder sizes vary in size between –35 mesh to 200 mesh [1]. Spence and Crawford [38] observed that the maxi- mum pore size in PE moldings reduced drastically when 40% of fine particles were applied in the poly- mer powder. Further increases did not significantly improve surface quality. Also, surface porosity re- duced with increasing fine particle content in the powder. They theorized that this improvement in surface porosity was as a result of the sieving action in RM which caused the finer particles to be deposit- ed onto the mold surface first. Olinek et al. [52] con- firmed this observation by uni-axially rotating a mix- ture of coarse and fine PE powder in a cylindrical mold that was provided with windows on the side walls. Experiments showed that at low heating rates the fine particles tended to segregate themselves at the surface of the heated mold. 3.2. Mechanism of bubble removal For the specific case of RM, Rao and Throne [12] and Progelhof et al. [55] incorrectly theorized that bubbles either slowly migrated to the free surface or remained encapsulated in the polymer after quench- ing. Kelly [56], on the other hand, observed that the bubbles formed during sintering remained stationary due to high melt viscosity. Instead, oxygen (more soluble than nitrogen in PE) dissolved into the poly- mer melt as temperature and hence pressure within the bubble increased. Surface tension forces caused a reduction in bubble diameter, which in turn in- creased pressure within the bubble; and nitrogen also dissolved into the melt. The process repeated itself until the entire bubble diffused and at very long cycle times the voids disappeared. This bubble collapse mechanism is now widely accepted in RM. Crawford and Scott [57] discerned two separate and distinct bulk movements: progression of the molten polymer across the powder mass to the free surface; and the collapse of the powder particles into the melt 783PDF Image | Rotational molding: A review

PDF Search Title:

Rotational molding: A reviewOriginal File Name Searched:

Rotational_molding_A_review_of_the_models_and_mate.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |