PDF Publication Title:

Text from PDF Page: 011

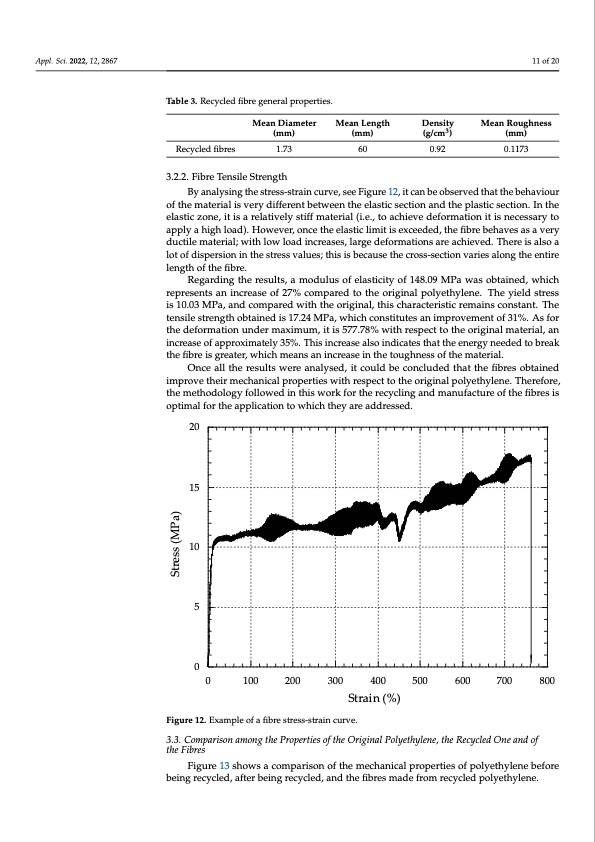

Appl. Sci. 2022, 12, 2867 11 of 20 Table 3. Recycled fibre general properties. Mean Diameter (mm) Recycled fibres 1.73 3.2.2. Fibre Tensile Strength Mean Length (mm) 60 Density (g/cm3 ) 0.92 Mean Roughness (mm) 0.1173 By analysing the stress-strain curve, see Figure 12, it can be observed that the behaviour of the material is very different between the elastic section and the plastic section. In the elastic zone, it is a relatively stiff material (i.e., to achieve deformation it is necessary to apply a high load). However, once the elastic limit is exceeded, the fibre behaves as a very ductile material; with low load increases, large deformations are achieved. There is also a lot of dispersion in the stress values; this is because the cross-section varies along the entire length of the fibre. Regarding the results, a modulus of elasticity of 148.09 MPa was obtained, which represents an increase of 27% compared to the original polyethylene. The yield stress is 10.03 MPa, and compared with the original, this characteristic remains constant. The tensile strength obtained is 17.24 MPa, which constitutes an improvement of 31%. As for the deformation under maximum, it is 577.78% with respect to the original material, an increase of approximately 35%. This increase also indicates that the energy needed to break the fibre is greater, which means an increase in the toughness of the material. Once all the results were analysed, it could be concluded that the fibres obtained Appl. Sci. 2022, 12, ixmFOpRroPvEeERthReEiVrImEWechanical properties with respect to the original polyethylene. Therefore, 1 the methodology followed in this work for the recycling and manufacture of the fibres is optimal for the application to which they are addressed. 20 15 10 5 0 0 100 200 300 400 500 Strain(%) 600 700 800 Figure 12. Example of a fibre stress-strain curve. Figure 12. Example of a fibre stress-strain curve. 3.3. Comparison among the Properties of the Original Polyethylene, the Recycled One and of the Fibres 3.3. Comparison among the Properties of the Original Polyethylene, the Recycled One and Fibres Figure 13 shows a comparison of the mechanical properties of polyethylene before Figure 13 shows a comparison of the mechanical properties of polyethylene being recycled, after being recycled, and the fibres made from recycled polyethylene. being recycled, after being recycled, and the fibres made from recycled polyethylen 250 13 12 2 o b Stress (MPa)PDF Image | Recycled Polyethylene Fibres for Structural Concrete

PDF Search Title:

Recycled Polyethylene Fibres for Structural ConcreteOriginal File Name Searched:

applsci-12-02867.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |