PDF Publication Title:

Text from PDF Page: 079

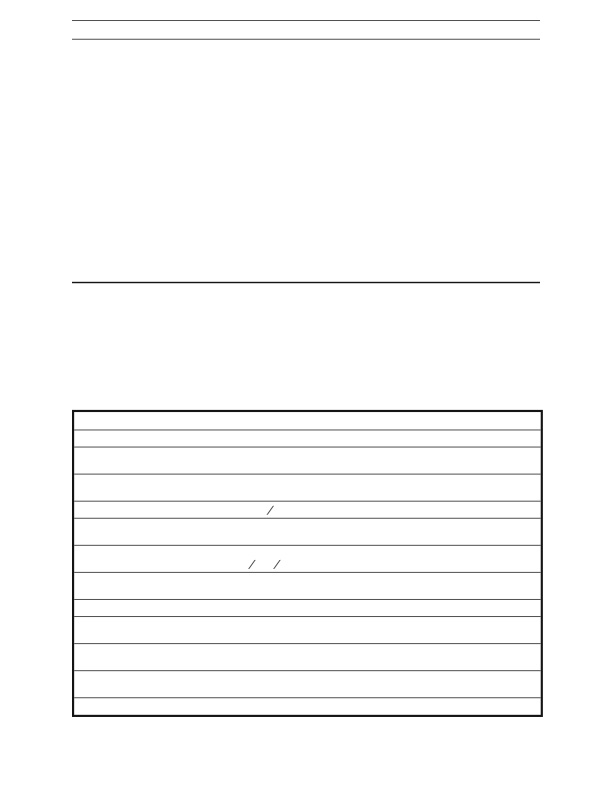

Composite Materials Marine Composites Carbon Fibers The terms �carbon� and �graphite� fibers are typically used interchangeably, although graphite technically refers to fibers that are greater than 99% carbon composition versus 93 to 95% for PAN-base fibers. All continuous carbofnibers produced to date are made from organic precursors, which in addition to PAN (polyacrylonitrile), include rayon and pitches, with the latter two generally used for low modulus fibers. Carbon fibers offer the highest strength and stiffness of all commonly used reinforcement fibers. The fibers are not subject to stress rupture or stress corrosion, as with glass and aramids. High temperature performance is particularly outstanding. The major drawback to the PAN-base fibers is their relative cost, which is a function of high precursor costs and an energy intensive manufacturing process. Table 2-4 shows some comparative fiber performance data. Reinforcement Construction Reinforcement materials are combined with resin systems in a variety of forms to create structural laminates. The percent of manufacturers using various reinforcement styles is represented in Figure 2-5. Table 2-5 provides definitions for the various forms of reinforcement materials. Some of the lower strength non-continous configurations are limited to fiberglass due to processing and economic considerations. Table 2-5 Description of Various Forms of Reinforcements [Shell, Epon fi Resins for Fiberglass Reinforced Plastics ] Form Description Principal Processes Filaments Fibers as initially drawn Processed further before use Continuous Strands Basic filaments gathered together in Processed further before use continuous bundles Yarns Twisted strands (treated with Processed further before use after-finish) Chopped Strands Strands chopped 14 to 2 inches Injection molding; matched die Rovings Strands bundled together like rope but Filament winding; sheet molding; not twisted spray-up; pultrusion Milled Fibers Continuous strands hammermilled into Compounding; casting; reinforced short lengths 132 to 18 inches long reaction injection molding (RRIM) Reinforcing Mats Nonwoven random matting consisting of Hand lay-up; resin transfer molding continuous or chopped strands (RTM); centrifugal casting Woven Fabric Cloth woven from yarns Hand lay-up; prepreg Woven Roving Strands woven like fabric but coarser Hand or machine lay-up; resin and heavier transfer molding (RTM) Spun Roving Continuous single strand looped on Processed further before use itself many times and held with a twist Nonwoven Fabrics Similar to matting but made with Hand or machine lay-up; resin unidirectional rovings in sheet form transfer molding (RTM) Surfacing Mats Random mat of monofilaments Hand lay-up; die molding; pultrusion 66PDF Image | Marine Componsites

PDF Search Title:

Marine ComponsitesOriginal File Name Searched:

MARINE_COMPOSITES.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |