PDF Publication Title:

Text from PDF Page: 076

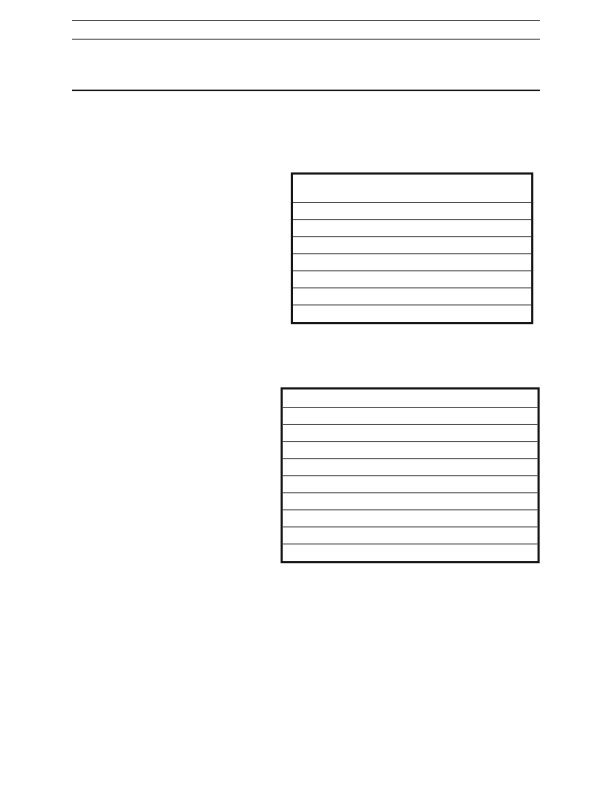

Chapter Two MATERIALS Reinforcement Materials Fiberglass Glass fibers account for over 90% of the fibers used in reinforced plastics because they are inexpensive to produce and have relatively good strength to weight characteristics. Additionally, glass fibers exhibit good chemical resistance and Designation processability. The excellent tensile strength of glass fibers, however, may deteriorate when loads are applied for long periods of time. [2-1] Continuous glass fibers are formed by extruding molten glass to filament diameters between 5 and 25 micrometers. Table 2-1 depicts the designations of fiber diameters commonly used in the FRP industry. Individual filaments are coated with a sizing to reduce abrasion and then combined into a strand of either 102 or 204 filaments. The sizing acts as coupling agent during resin impregnation.Silicone Dioxide Table 2-2 lists the composition by weight for both E- and S-glass. Table 2-3 lists Calcium Oxide some typical glass finishes and their Aluminum Oxide compatible resin systems. E-glass (limeBoron Oxide aluminum borosilicate) is the most Sodium & Potassium Oxide common reinforcement used in marineMagnesium Oxide laminates because of its good strength properties and resistance to waterIron Oxide degradation. S-glass (silicon dioxide, Titanium Oxide aluminum and magnesium oxides) exhibitsFluorides about one third better tensile strength, and in general, demonstrates better fatigue resistance. The cost for this variety of glass fiber is about three to four times that of E-glass. Table 2-4 contains data on raw E-glass and S-glass fibers. Table 2-1 Glass Fiber Diameter Designations [Shell, Epon fi Resins for Fiberglass C D E G H K Reinforced Plastics ] Micrometers Mils (10-6 meters) 0.18 4.57 0.23 5.84 0.28 7.11 0.38 9.65 0.42 10.57 0.53 13.46 Table 2-2 Glass Composition by Weight for a E-Glass S-Glass Polymer Fibers The most common aramid fiber is Kevlardeveloped by DuPont. This is the predominant organic reinforcing fiber, whose use dates to the early 1970s as a replacement for steel belting in tires. The outstanding features of aramids are low weight, high tensile strength and modulus, impact and fatigue resistance, and weaveability. Compressive performance of fi 63 DE 0.25 6.35 E- and S-Glass [BGF] 52 - 56% 16 - 25% 12 - 16% 5 - 10% 0 - 2% 0 - 5% .05 - .4% 0 - .8% 0 - 1.0% 64 - 66% 0 - .3% 24 - 26% � 0 - .3% 9 - 11% 0 - .3% � �PDF Image | Marine Componsites

PDF Search Title:

Marine ComponsitesOriginal File Name Searched:

MARINE_COMPOSITES.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |