PDF Publication Title:

Text from PDF Page: 015

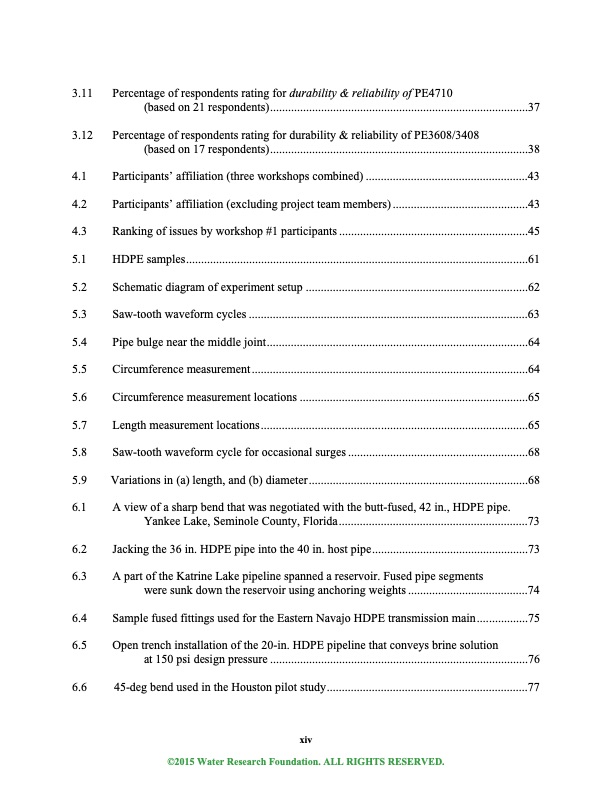

3.11 Percentage of respondents rating for durability & reliability of PE4710 (based on 21 respondents)......................................................................................37 3.12 Percentage of respondents rating for durability & reliability of PE3608/3408 (based on 17 respondents)......................................................................................38 4.1 Participants’ affiliation (three workshops combined) ......................................................43 4.2 Participants’ affiliation (excluding project team members) .............................................43 4.3 Ranking of issues by workshop #1 participants ...............................................................45 5.1 HDPE samples..................................................................................................................61 5.2 Schematic diagram of experiment setup ..........................................................................62 5.3 Saw-tooth waveform cycles .............................................................................................63 5.4 Pipe bulge near the middle joint .......................................................................................64 5.5 Circumference measurement ............................................................................................64 5.6 Circumference measurement locations ............................................................................65 5.7 Length measurement locations .........................................................................................65 5.8 Saw-tooth waveform cycle for occasional surges ............................................................68 5.9 Variations in (a) length, and (b) diameter.........................................................................68 6.1 A view of a sharp bend that was negotiated with the butt-fused, 42 in., HDPE pipe. Yankee Lake, Seminole County, Florida...............................................................73 6.2 Jacking the 36 in. HDPE pipe into the 40 in. host pipe....................................................73 6.3 A part of the Katrine Lake pipeline spanned a reservoir. Fused pipe segments were sunk down the reservoir using anchoring weights ........................................74 6.4 Sample fused fittings used for the Eastern Navajo HDPE transmission main.................75 6.5 Open trench installation of the 20-in. HDPE pipeline that conveys brine solution at 150 psi design pressure ......................................................................................76 6.6 45-deg bend used in the Houston pilot study...................................................................77 xiv ©2015 Water Research Foundation. ALL RIGHTS RESERVED.PDF Image | Large Diameter HDPE Pipe for Water Main Applications

PDF Search Title:

Large Diameter HDPE Pipe for Water Main ApplicationsOriginal File Name Searched:

4485.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |