PDF Publication Title:

Text from PDF Page: 007

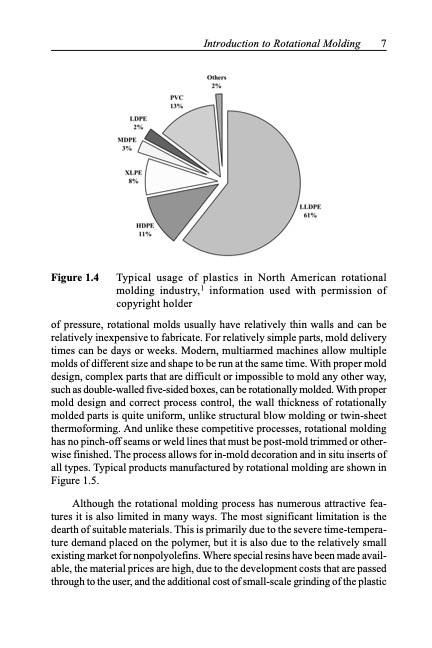

Introduction to Rotational Molding 7 Figure 1.4 Typical usage of plastics in North American rotational molding industry,1 information used with permission of copyright holder of pressure, rotational molds usually have relatively thin walls and can be relatively inexpensive to fabricate. For relatively simple parts, mold delivery times can be days or weeks. Modern, multiarmed machines allow multiple molds of different size and shape to be run at the same time. With proper mold design, complex parts that are difficult or impossible to mold any other way, such as double-walled five-sided boxes, can be rotationally molded. With proper mold design and correct process control, the wall thickness of rotationally molded parts is quite uniform, unlike structural blow molding or twin-sheet thermoforming. And unlike these competitive processes, rotational molding has no pinch-off seams or weld lines that must be post-mold trimmed or other- wise finished. The process allows for in-mold decoration and in situ inserts of all types. Typical products manufactured by rotational molding are shown in Figure 1.5. Although the rotational molding process has numerous attractive fea- tures it is also limited in many ways. The most significant limitation is the dearth of suitable materials. This is primarily due to the severe time-tempera- ture demand placed on the polymer, but it is also due to the relatively small existing market for nonpolyolefins. Where special resins have been made avail- able, the material prices are high, due to the development costs that are passed through to the user, and the additional cost of small-scale grinding of the plasticPDF Image | INTRODUCTION TO ROTATIONAL MOLDING 1

PDF Search Title:

INTRODUCTION TO ROTATIONAL MOLDING 1Original File Name Searched:

Introduction-To-Rotational-Moulding.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |