PDF Publication Title:

Text from PDF Page: 006

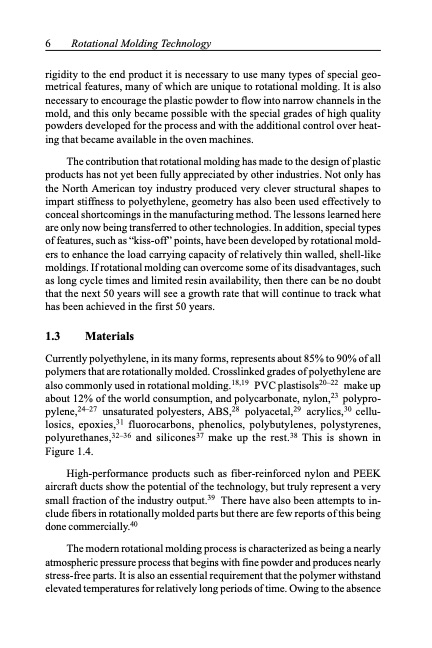

6 Rotational Molding Technology rigidity to the end product it is necessary to use many types of special geo- metrical features, many of which are unique to rotational molding. It is also necessary to encourage the plastic powder to flow into narrow channels in the mold, and this only became possible with the special grades of high quality powders developed for the process and with the additional control over heat- ing that became available in the oven machines. The contribution that rotational molding has made to the design of plastic products has not yet been fully appreciated by other industries. Not only has the North American toy industry produced very clever structural shapes to impart stiffness to polyethylene, geometry has also been used effectively to conceal shortcomings in the manufacturing method. The lessons learned here are only now being transferred to other technologies. In addition, special types of features, such as ìkiss-offî points, have been developed by rotational mold- ers to enhance the load carrying capacity of relatively thin walled, shell-like moldings. If rotational molding can overcome some of its disadvantages, such as long cycle times and limited resin availability, then there can be no doubt that the next 50 years will see a growth rate that will continue to track what has been achieved in the first 50 years. 1.3 Materials Currently polyethylene, in its many forms, represents about 85% to 90% of all polymers that are rotationally molded. Crosslinked grades of polyethylene are also commonly used in rotational molding.18,19 PVC plastisols20ñ22 make up about 12% of the world consumption, and polycarbonate, nylon,23 polypro- pylene,24ñ27 unsaturated polyesters, ABS,28 polyacetal,29 acrylics,30 cellu- losics, epoxies,31 fluorocarbons, phenolics, polybutylenes, polystyrenes, polyurethanes,32ñ36 and silicones37 make up the rest.38 This is shown in Figure 1.4. High-performance products such as fiber-reinforced nylon and PEEK aircraft ducts show the potential of the technology, but truly represent a very small fraction of the industry output.39 There have also been attempts to in- clude fibers in rotationally molded parts but there are few reports of this being done commercially.40 The modern rotational molding process is characterized as being a nearly atmospheric pressure process that begins with fine powder and produces nearly stress-free parts. It is also an essential requirement that the polymer withstand elevated temperatures for relatively long periods of time. Owing to the absencePDF Image | INTRODUCTION TO ROTATIONAL MOLDING 1

PDF Search Title:

INTRODUCTION TO ROTATIONAL MOLDING 1Original File Name Searched:

Introduction-To-Rotational-Moulding.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |