PDF Publication Title:

Text from PDF Page: 006

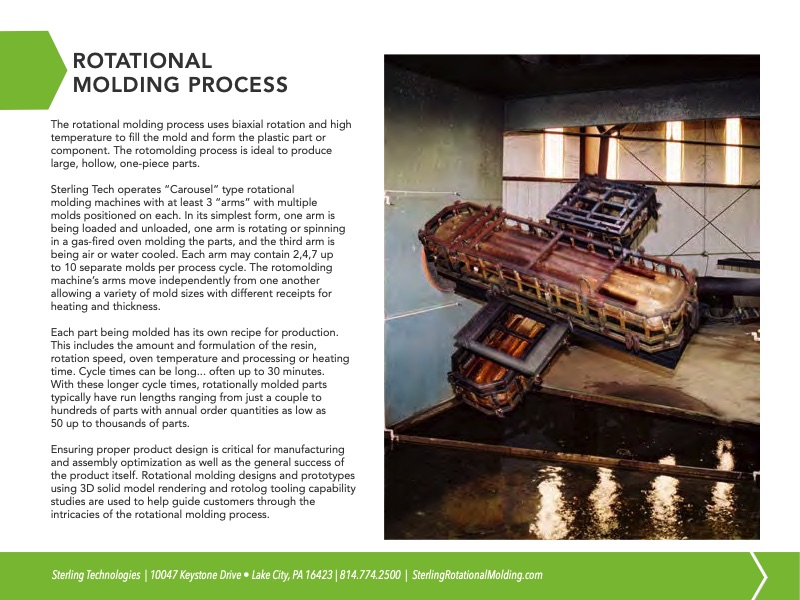

ROTATIONAL MOLDING PROCESS The rotational molding process uses biaxial rotation and high temperature to fill the mold and form the plastic part or component. The rotomolding process is ideal to produce large, hollow, one-piece parts. Sterling Tech operates “Carousel” type rotational molding machines with at least 3 “arms” with multiple molds positioned on each. In its simplest form, one arm is being loaded and unloaded, one arm is rotating or spinning in a gas-fired oven molding the parts, and the third arm is being air or water cooled. Each arm may contain 2,4,7 up to 10 separate molds per process cycle. The rotomolding machine’s arms move independently from one another allowing a variety of mold sizes with different receipts for heating and thickness. Each part being molded has its own recipe for production. This includes the amount and formulation of the resin, rotation speed, oven temperature and processing or heating time. Cycle times can be long... often up to 30 minutes. With these longer cycle times, rotationally molded parts typically have run lengths ranging from just a couple to hundreds of parts with annual order quantities as low as 50 up to thousands of parts. Ensuring proper product design is critical for manufacturing and assembly optimization as well as the general success of the product itself. Rotational molding designs and prototypes using 3D solid model rendering and rotolog tooling capability studies are used to help guide customers through the intricacies of the rotational molding process. Sterling Technologies | 10047 Keystone Drive • Lake City, PA 16423 | 814.774.2500 | SterlingRotationalMolding.comPDF Image | GUIDE TO PLASTIC ROTATIONAL MOLDING

PDF Search Title:

GUIDE TO PLASTIC ROTATIONAL MOLDINGOriginal File Name Searched:

GuideToPlasticRotationalMolding.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |