PDF Publication Title:

Text from PDF Page: 005

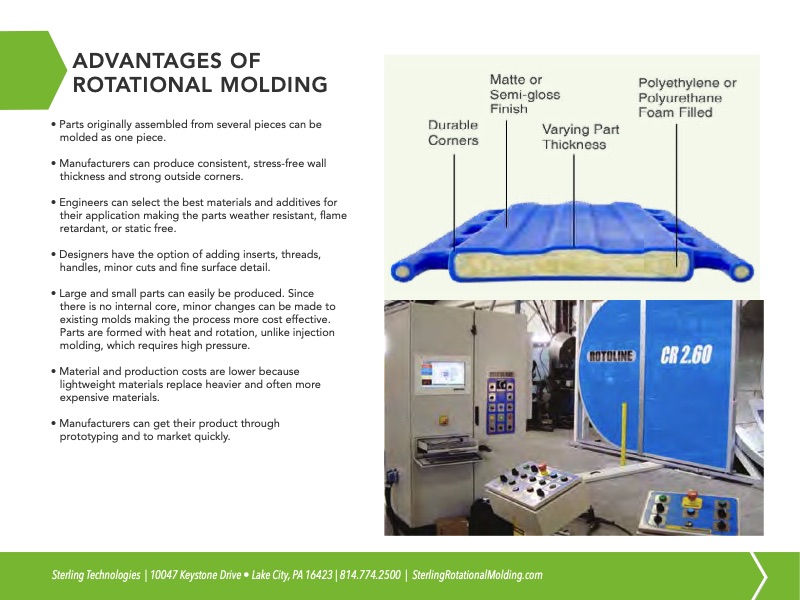

ADVANTAGES OF ROTATIONAL MOLDING • Parts originally assembled from several pieces can be molded as one piece. • Manufacturers can produce consistent, stress-free wall thickness and strong outside corners. • Engineers can select the best materials and additives for their application making the parts weather resistant, flame retardant, or static free. • Designers have the option of adding inserts, threads, handles, minor cuts and fine surface detail. • Large and small parts can easily be produced. Since there is no internal core, minor changes can be made to existing molds making the process more cost effective. Parts are formed with heat and rotation, unlike injection molding, which requires high pressure. • Material and production costs are lower because lightweight materials replace heavier and often more expensive materials. • Manufacturers can get their product through prototyping and to market quickly. Sterling Technologies | 10047 Keystone Drive • Lake City, PA 16423 | 814.774.2500 | SterlingRotationalMolding.comPDF Image | GUIDE TO PLASTIC ROTATIONAL MOLDING

PDF Search Title:

GUIDE TO PLASTIC ROTATIONAL MOLDINGOriginal File Name Searched:

GuideToPlasticRotationalMolding.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |