PDF Publication Title:

Text from PDF Page: 024

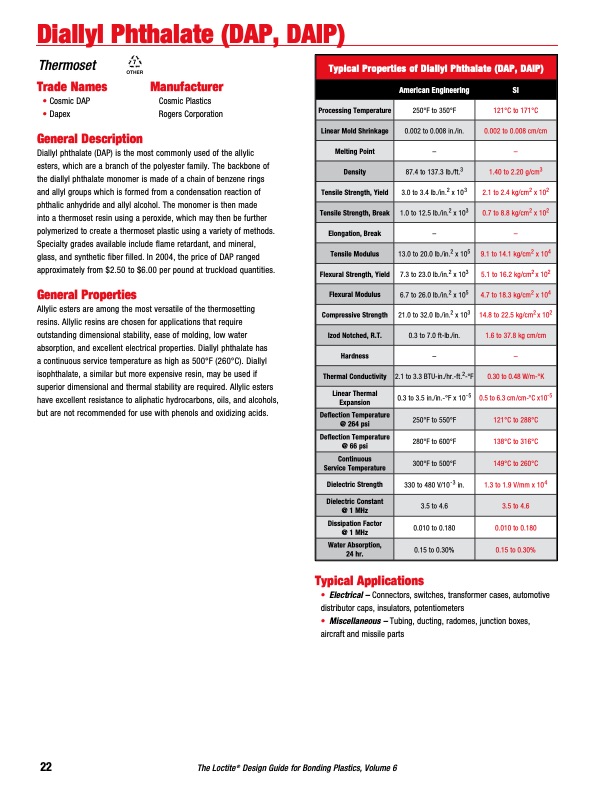

Diallyl Phthalate (DAP, DAIP) Typical Properties of Diallyl Phthalate (DAP, DAIP) American Engineering SI Processing Temperature 250°F to 350°F 121°C to 171°C Linear Mold Shrinkage 0.002 to 0.008 in./in. 0.002 to 0.008 cm/cm Melting Point – – Density 87.4 to 137.3 lb./ft.3 1.40 to 2.20 g/cm3 Tensile Strength, Yield 3.0 to 3.4 lb./in.2 x 103 2.1 to 2.4 kg/cm2 x 102 Tensile Strength, Break 1.0 to 12.5 lb./in.2 x 103 0.7 to 8.8 kg/cm2 x 102 Elongation, Break – – Tensile Modulus 13.0 to 20.0 lb./in.2 x 105 9.1 to 14.1 kg/cm2 x 104 Flexural Strength, Yield 7.3 to 23.0 lb./in.2 x 103 5.1 to 16.2 kg/cm2 x 102 Flexural Modulus 6.7 to 26.0 lb./in.2 x 105 4.7 to 18.3 kg/cm2 x 104 Compressive Strength 21.0 to 32.0 lb./in.2 x 103 14.8 to 22.5 kg/cm2 x 102 Izod Notched, R.T. 0.3 to 7.0 ft-lb./in. 1.6 to 37.8 kg cm/cm Hardness – – Thermal Conductivity 2.1 to 3.3 BTU-in./hr.-ft.2-°F 0.30 to 0.48 W/m-°K Linear Thermal Expansion 0.3 to 3.5 in./in.-°F x 10-5 0.5 to 6.3 cm/cm-°C x10-5 Deflection Temperature @ 264 psi 250°F to 550°F 121°C to 288°C Deflection Temperature @ 66 psi 280°F to 600°F 138°C to 316°C Continuous Service Temperature 300°F to 500°F 149°C to 260°C Dielectric Strength 330 to 480 V/10-3 in. 1.3 to 1.9 V/mm x 104 Dielectric Constant @ 1 MHz 3.5 to 4.6 3.5 to 4.6 Dissipation Factor @ 1 MHz 0.010 to 0.180 0.010 to 0.180 Water Absorption, 24 hr. 0.15 to 0.30% 0.15 to 0.30% Thermoset Trade Names • Cosmic DAP • Dapex General Description Manufacturer Cosmic Plastics Rogers Corporation Diallyl phthalate (DAP) is the most commonly used of the allylic esters, which are a branch of the polyester family. The backbone of the diallyl phthalate monomer is made of a chain of benzene rings and allyl groups which is formed from a condensation reaction of phthalic anhydride and allyl alcohol. The monomer is then made into a thermoset resin using a peroxide, which may then be further polymerized to create a thermoset plastic using a variety of methods. Specialty grades available include flame retardant, and mineral, glass, and synthetic fiber filled. In 2004, the price of DAP ranged approximately from $2.50 to $6.00 per pound at truckload quantities. General Properties Allylic esters are among the most versatile of the thermosetting resins. Allylic resins are chosen for applications that require outstanding dimensional stability, ease of molding, low water absorption, and excellent electrical properties. Diallyl phthalate has a continuous service temperature as high as 500°F (260°C). Diallyl isophthalate, a similar but more expensive resin, may be used if superior dimensional and thermal stability are required. Allylic esters have excellent resistance to aliphatic hydrocarbons, oils, and alcohols, but are not recommended for use with phenols and oxidizing acids. 22 The Loctite® Design Guide for Bonding Plastics, Volume 6 Typical Applications • Electrical – Connectors, switches, transformer cases, automotive distributor caps, insulators, potentiometers • Miscellaneous – Tubing, ducting, radomes, junction boxes, aircraft and missile partsPDF Image | Design Guide for Bonding Plastics Volume 6 LT-2197

PDF Search Title:

Design Guide for Bonding Plastics Volume 6 LT-2197Original File Name Searched:

henkel-loctite-design-guide-plastic-bonding.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |