PDF Publication Title:

Text from PDF Page: 019

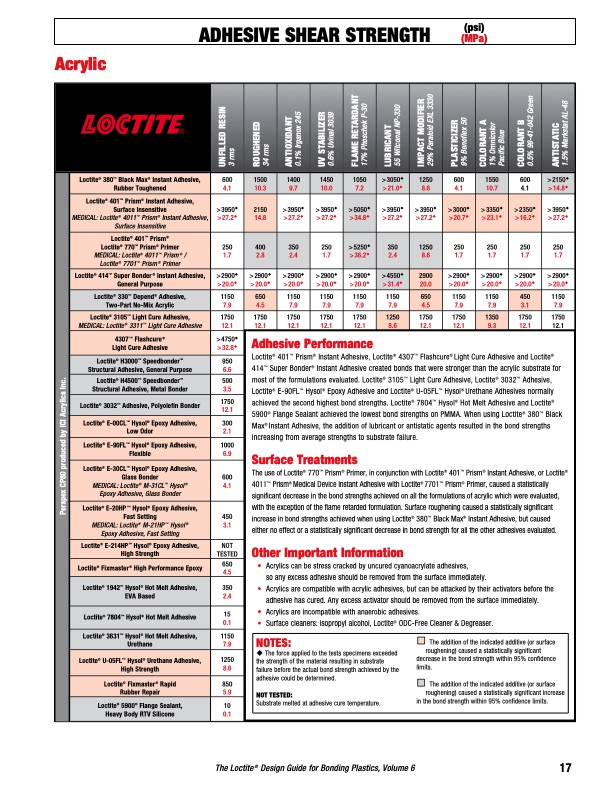

Acrylic ADHESIVE SHEAR STRENGTH (MPa) (psi) Loctite® 380TM Black Max® Instant Adhesive, Rubber Toughened Loctite® 3105TM Light Cure Adhesive, MEDICAL: Loctite® 3311TM Light Cure Adhesive 600 4.1 > 3950u > 27.2u 1150 7.9 1750 12.1 1500 10.3 1750 12.1 1400 9.7 1750 12.1 1450 10.0 1750 12.1 1050 7.2 1150 7.9 1750 12.1 > 3050u > 21.0u 1150 7.9 1250 8.6 > 3950u > 27.2u 1750 12.1 600 4.1 1150 7.9 1750 12.1 1550 10.7 1150 7.9 600 4.1 1750 12.1 > 2150u > 14.8u Loctite® 401TM Prism® Instant Adhesive, Surface Insensitive MEDICAL: Loctite® 4011TM Prism® Instant Adhesive, Surface Insensitive 2150 14.8 > 3950u > 27.2u > 3950u > 27.2u > 5050u > 34.8u > 3950u > 27.2u > 3000u > 20.7u > 3350u > 23.1u > 2350u > 16.2u > 3950u > 27.2u Loctite® 401TM Prism® Loctite® 770TM Prism® Primer MEDICAL: Loctite® 4011TM Prism® / Loctite® 7701TM Prism® Primer 250 1.7 400 2.8 350 2.4 250 1.7 > 5250u > 36.2u 350 2.4 1250 8.6 250 1.7 250 1.7 250 1.7 250 1.7 Loctite® 414TM Super Bonder® Instant Adhesive, General Purpose > 2900u > 20.0u > 2900u > 20.0u > 2900u > 20.0u > 2900u > 20.0u > 2900u > 20.0u > 4550u > 31.4u 2900 20.0 > 2900u > 20.0u > 2900u > 20.0u > 2900u > 20.0u > 2900u > 20.0u Loctite® 330TM Depend® Adhesive, Two-Part No-Mix Acrylic 650 4.5 1150 7.9 1150 7.9 650 4.5 450 3.1 1150 7.9 1250 8.6 1350 9.3 1750 12.1 4307TM Flashcure® Light Cure Adhesive > 4750u > 32.8u Adhesive Performance Loctite® 401TM Prism® Instant Adhesive, Loctite® 4307TM Flashcure® Light Cure Adhesive and Loctite® 414TM Super Bonder® Instant Adhesive created bonds that were stronger than the acrylic substrate for Loctite® H3000TM SpeedbonderTM Structural Adhesive, General Purpose 950 6.6 Loctite® H4500TM SpeedbonderTM Structural Adhesive, Metal Bonder Loctite® 3032TM Adhesive, Polyolefin Bonder 500 3.5 1750 12.1 most of Loctite® the formulations evaluated. Loctite® 3105TM Light Cure E-90FLTM Hysol® Epoxy Adhesive and Loctite® U-05FLTM achieved the second highest bond strengths. Loctite® 7804TM Hysol® Hot Melt Adhesive and Loctite® 5900® Flange Sealant achieved the lowest bond strengths on PMMA. When using Loctite® 380TM Black Max® Instant Adhesive, the addition of lubricant or antistatic agents resulted in the bond strengths increasing from average strengths to sub Surface Treatments The use of Loctite® 770TM Prism® Primer, in conjunction with Loctite® 401TM Prism® Instant Adhesive, or Loctite® 4011TM Prism® Medical Device Instant Adhesive with Loctite® 7701TM Prism® Primer, caused a statistically significant decrease in the bond strengths achieved on all the formulations of acrylic which were evaluated, Adhesive, Loctite® 3032TM Adhesive, Hysol® Urethane Adhesives normally Loctite® E-00CLTM Hysol® Epoxy Adhesive, Low Odor 300 2.1 Loctite® E-90FLTM Hysol® Epoxy Adhesive, Flexible 1000 6.9 Loctite® E-30CLTM Hysol® Epoxy Adhesive, Glass Bonder MEDICAL: Loctite® M-31CLTM Hysol® Epoxy Adhesive, Glass Bonder 600 4.1 Loctite® E-20HPTM Hysol® Epoxy Adhesive, Fast Setting MEDICAL: Loctite® M-21HPTM Hysol® Epoxy Adhesive, Fast Setting Loctite® E-214HPTM Hysol® Epoxy Adhesive, High Strength 450 3.1 NOT TESTED 650 4.5 with the exception of the flame retarded formulation. Surface roughening caused a statistically significant increase in bond strengths achieved when using Loctite® 380TM Black Max® Instant Adhesive, but caused either no effect or a statistically significant decrease in bond strength for all the other adhesives evaluated. Other Important Inform ation Loctite® Fixmaster® High Performance Epoxy • Acrylics can be stress cracked by uncured cyanoacrylate adhesives, so any excess adhesive should be removed from the surface immediately. • Acrylics are compatible with acrylic adhesives, but can be attacked by their activators before the adhesive has cured. Any excess activator should be removed from the surface immediately. Loctite® 1942TM Hysol® Hot Melt Adhesive, EVA Based Loctite® U-05FLTM Hysol® Urethane Adhesive, High Strength Loctite® Fixmaster® Rapid Rubber Repair Loctite® 5900® Flange Sealant, Heavy Body RTV Silicone 350 2.4 Loctite® 7804TM Hysol® Hot Melt Adhesive 15 0.1 1250 8.6 850 5.9 10 0.1 • Acrylics are incompatible with anaerobic adhesives. • Surface cleaners: isopropyl alcohol, Loctite® ODC-Free Cleaner & Degreaser. Loctite® 3631TM Hysol® Hot Melt Adhesive, Urethane 1150 7.9 NOTES: u The force applied to the tests specimens exceeded the strength of the material resulting in substrate failure before the actual bond strength achieved by the adhesive could be determined. NOT TESTED: Substrate melted at adhesive cure temperature. The addition of the indicated additive (or surface roughening) caused a statistically significant decrease in the bond strength within 95% confidence limits. The addition of the indicated additive (or surface roughening) caused a statistically significant increase in the bond strength within 95% confidence limits. strate failure. The Loctite® Design Guide for Bonding Plastics, Volume 6 17 Perspex CP80 produced by ICI Acrylics Inc. Unfilled Resin 3 rms RoUghened 34 rms AntioxidAnt 0.1% Irganox 245 UV stAbilizeR 0.6% Uvinal 3039 flAme RetARdAnt 17% Phoschek P-30 lUbRicAnt 55 Witconal NP-330 impAct modifieR 29% Paraloid EXL 3330 plAsticizeR 9% Benoflex 50 coloRAnt A 1% Omnicolor Pacific Blue coloRAnt b 0.5% 99-41-042 Green AntistAtic 1.5% Markstat AL-48PDF Image | Design Guide for Bonding Plastics Volume 6 LT-2197

PDF Search Title:

Design Guide for Bonding Plastics Volume 6 LT-2197Original File Name Searched:

henkel-loctite-design-guide-plastic-bonding.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |