PDF Publication Title:

Text from PDF Page: 010

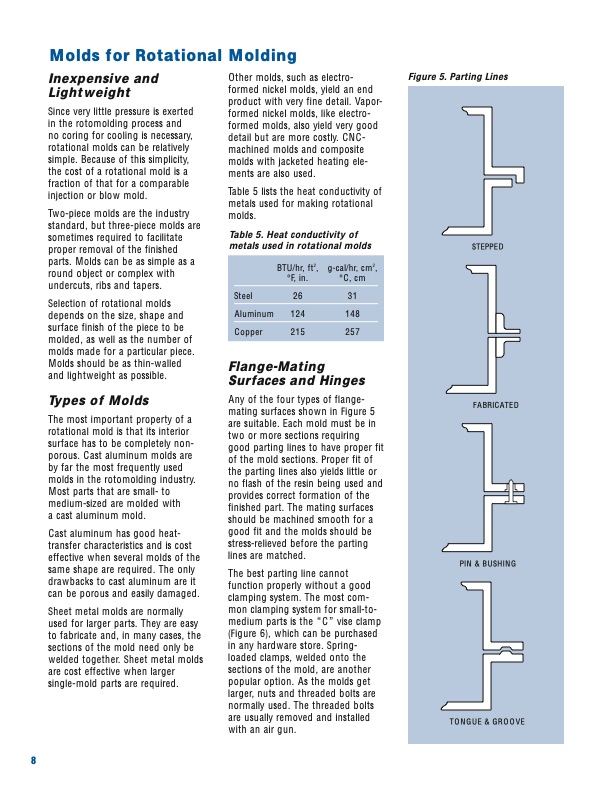

Molds for Rotational Molding Inexpensive and Lightweight Since very little pressure is exerted in the rotomolding process and no coring for cooling is necessary, rotational molds can be relatively simple. Because of this simplicity, the cost of a rotational mold is a fraction of that for a comparable injection or blow mold. Two-piece molds are the industry standard, but three-piece molds are sometimes required to facilitate proper removal of the finished parts. Molds can be as simple as a round object or complex with undercuts, ribs and tapers. Selection of rotational molds depends on the size, shape and surface finish of the piece to be molded, as well as the number of molds made for a particular piece. Molds should be as thin-walled and lightweight as possible. Types of Molds The most important property of a rotational mold is that its interior surface has to be completely non- porous. Cast aluminum molds are by far the most frequently used molds in the rotomolding industry. Most parts that are small- to medium-sized are molded with a cast aluminum mold. Cast aluminum has good heat- transfer characteristics and is cost effective when several molds of the same shape are required. The only drawbacks to cast aluminum are it can be porous and easily damaged. Sheet metal molds are normally used for larger parts. They are easy to fabricate and, in many cases, the sections of the mold need only be welded together. Sheet metal molds are cost effective when larger single-mold parts are required. Other molds, such as electro- formed nickel molds, yield an end product with very fine detail. Vapor- formed nickel molds, like electro- formed molds, also yield very good detail but are more costly. CNC- machined molds and composite molds with jacketed heating ele- ments are also used. Table 5 lists the heat conductivity of metals used for making rotational molds. Table 5. Heat conductivity of metals used in rotational molds Steel Aluminum Copper BTU/hr, ft2, °F, in. 26 124 215 g-cal/hr, cm2, °C, cm 31 148 257 Flange-Mating Surfaces and Hinges Any of the four types of flange- mating surfaces shown in Figure 5 are suitable. Each mold must be in two or more sections requiring good parting lines to have proper fit of the mold sections. Proper fit of the parting lines also yields little or no flash of the resin being used and provides correct formation of the finished part. The mating surfaces should be machined smooth for a good fit and the molds should be stress-relieved before the parting lines are matched. The best parting line cannot function properly without a good clamping system. The most com- mon clamping system for small-to- medium parts is the “C” vise clamp (Figure 6), which can be purchased in any hardware store. Spring- loaded clamps, welded onto the sections of the mold, are another popular option. As the molds get larger, nuts and threaded bolts are normally used. The threaded bolts are usually removed and installed with an air gun. Figure 5. Parting Lines STEPPED FABRICATED PIN & BUSHING TONGUE & GROOVE 8PDF Image | A Guide to Rotational Molding Equistar

PDF Search Title:

A Guide to Rotational Molding EquistarOriginal File Name Searched:

Guide_Rotational_Molding.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |