PDF Publication Title:

Text from PDF Page: 014

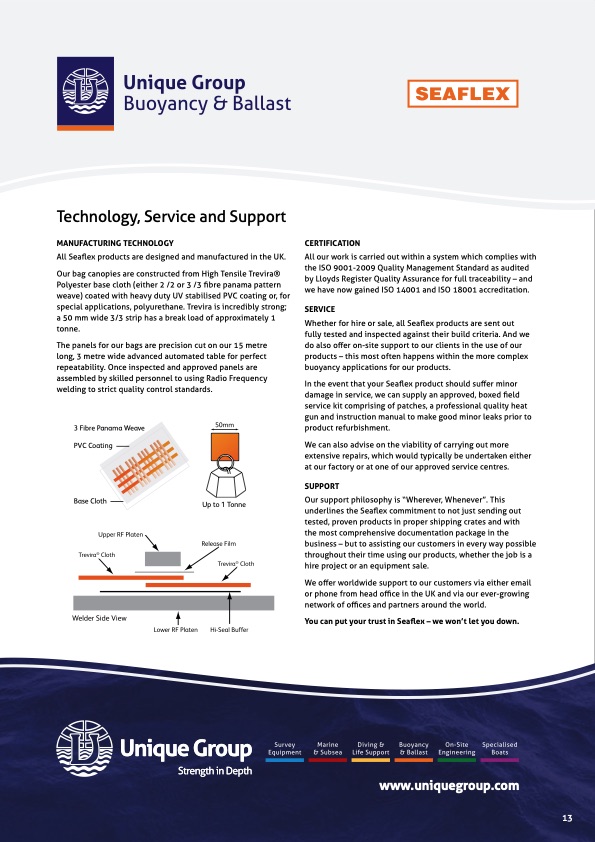

Technology, Service and Support MANUFACTURING TECHNOLOGY All Seaflex products are designed and manufactured in the UK. Our bag canopies are constructed from High Tensile Trevira® Polyester base cloth (either 2 /2 or 3 /3 fibre panama pattern weave) coated with heavy duty UV stabilised PVC coating or, for special applications, polyurethane. Trevira is incredibly strong; a 50 mm wide 3/3 strip has a break load of approximately 1 tonne. The panels for our bags are precision cut on our 15 metre long, 3 metre wide advanced automated table for perfect repeatability. Once inspected and approved panels are assembled by skilled personnel to using Radio Frequency welding to strict quality control standards. CERTIFICATION All our work is carried out within a system which complies with the ISO 9001-2009 Quality Management Standard as audited by Lloyds Register Quality Assurance for full traceability – and we have now gained ISO 14001 and ISO 18001 accreditation. SERVICE Whether for hire or sale, all Seaflex products are sent out fully tested and inspected against their build criteria. And we do also offer on-site support to our clients in the use of our products – this most often happens within the more complex buoyancy applications for our products. In the event that your Seaflex product should suffer minor damage in service, we can supply an approved, boxed field service kit comprising of patches, a professional quality heat gun and instruction manual to make good minor leaks prior to product refurbishment. We can also advise on the viability of carrying out more extensive repairs, which would typically be undertaken either at our factory or at one of our approved service centres. SUPPORT Our support philosophy is “Wherever, Whenever”. This underlines the Seaflex commitment to not just sending out tested, proven products in proper shipping crates and with the most comprehensive documentation package in the business – but to assisting our customers in every way possible throughout their time using our products, whether the job is a hire project or an equipment sale. We offer worldwide support to our customers via either email or phone from head office in the UK and via our ever-growing network of offices and partners around the world. You can put your trust in Seaflex – we won’t let you down. 3 Fibre Panama Weave PVC Coating Base Cloth Up to 1 Tonne www.uniquegroup.com 13PDF Image | Use of Buoyancy for Installation of HDPE

PDF Search Title:

Use of Buoyancy for Installation of HDPEOriginal File Name Searched:

Seaflex-Buoyancy-HDPE-Pipelines.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |