PDF Publication Title:

Text from PDF Page: 003

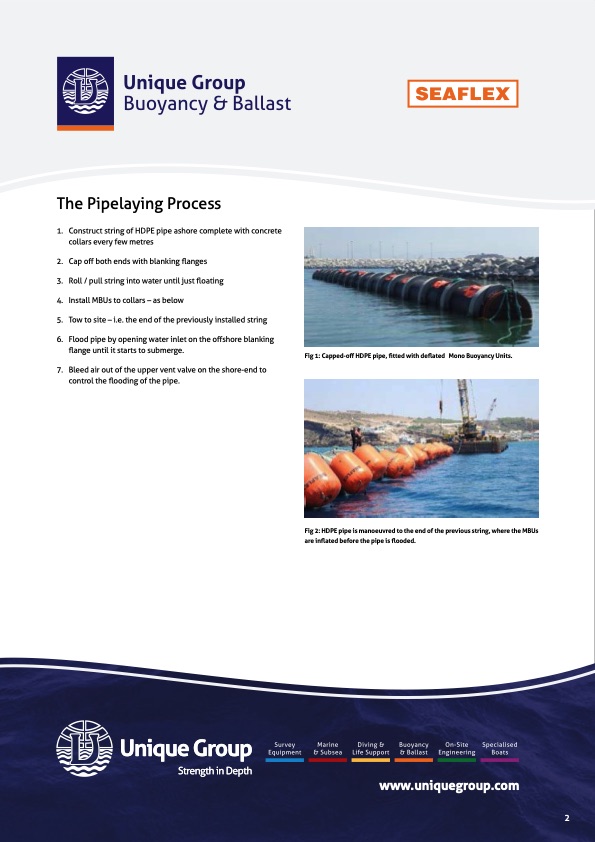

The Pipelaying Process 1. ConstructstringofHDPEpipeashorecompletewithconcrete collars every few metres 2. Capoffbothendswithblankingflanges 3. Roll/pullstringintowateruntiljustfloating 4. InstallMBUstocollars–asbelow 5. Towtosite–i.e.theendofthepreviouslyinstalledstring 6. Floodpipebyopeningwaterinletontheoffshoreblanking flange until it starts to submerge. 7. Bleedairoutoftheupperventvalveontheshore-endto control the flooding of the pipe. Fig1:Capped-offHDPEpipe,fittedwithdeflated MonoBuoyancyUnits. Fig 2: HDPE pipe is manoeuvred to the end of the previous string, where the MBUs are inflated before the pipe is flooded. www.uniquegroup.com 2PDF Image | Use of Buoyancy for Installation of HDPE

PDF Search Title:

Use of Buoyancy for Installation of HDPEOriginal File Name Searched:

Seaflex-Buoyancy-HDPE-Pipelines.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |