PDF Publication Title:

Text from PDF Page: 020

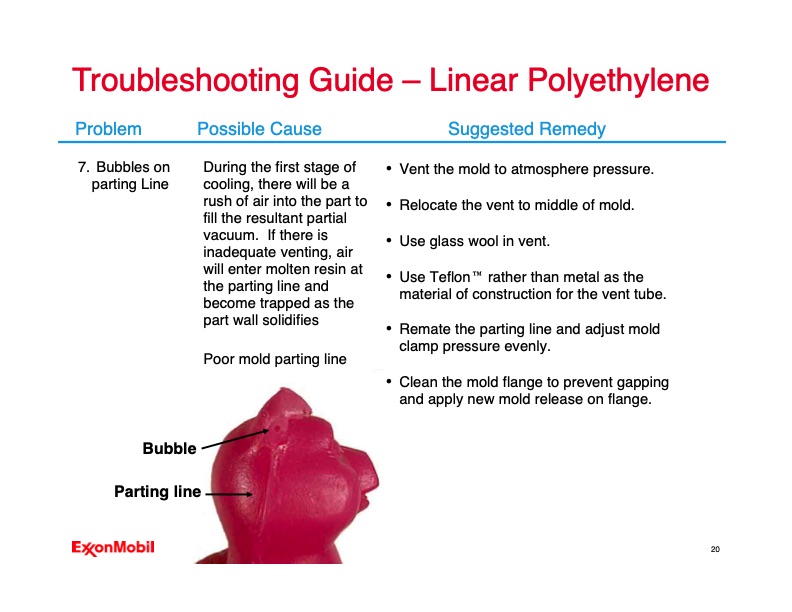

Troubleshooting Guide – Linear Polyethylene Problem Possible Cause Suggested Remedy 7. Bubbles on parting Line During the first stage of cooling, there will be a rush of air into the part to fill the resultant partial vacuum. If there is inadequate venting, air will enter molten resin at the parting line and become trapped as the part wall solidifies • • • • Vent the mold to atmosphere pressure. Bubble Parting line Poor mold parting line • • Remate the parting line and adjust mold clamp pressure evenly. Relocate the vent to middle of mold. Use glass wool in vent. Use Teflon rather than metal as the material of construction for the vent tube. Clean the mold flange to prevent gapping and apply new mold release on flange. 20PDF Image | Troubleshooting your rotomolding operation

PDF Search Title:

Troubleshooting your rotomolding operationOriginal File Name Searched:

cooke.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |