PDF Publication Title:

Text from PDF Page: 017

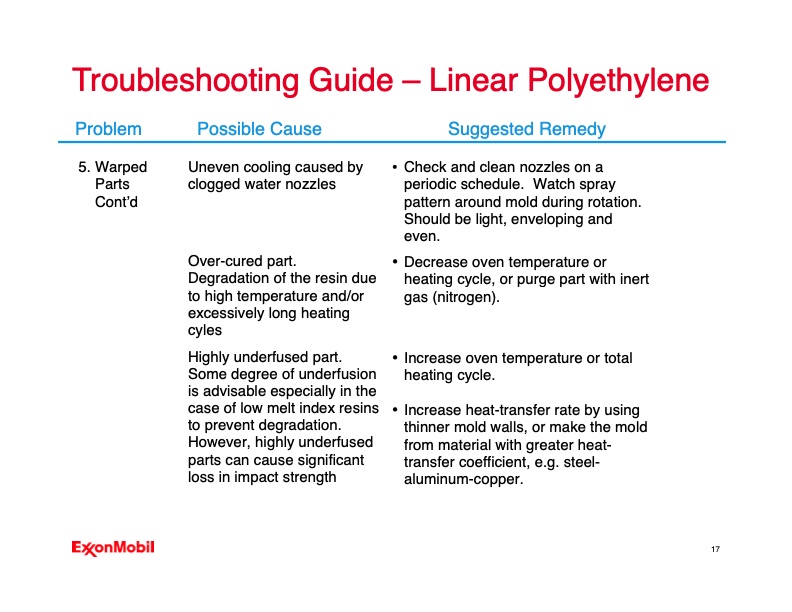

Troubleshooting Guide – Linear Polyethylene Problem Possible Cause Suggested Remedy 5. Warped Parts Uneven cooling caused by clogged water nozzles • Check and clean nozzles on a periodic schedule. Watch spray pattern around mold during rotation. Should be light, enveloping and even. Cont’d Over-cured part. Degradation of the resin due to high temperature and/or excessively long heating cyles • Decrease oven temperature or heating cycle, or purge part with inert gas (nitrogen). Highly underfused part. Some degree of underfusion is advisable especially in the case of low melt index resins to prevent degradation. However, highly underfused parts can cause significant loss in impact strength • Increase oven temperature or total heating cycle. • Increase heat-transfer rate by using thinner mold walls, or make the mold from material with greater heat- transfer coefficient, e.g. steel- aluminum-copper. 17PDF Image | Troubleshooting your rotomolding operation

PDF Search Title:

Troubleshooting your rotomolding operationOriginal File Name Searched:

cooke.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |