PDF Publication Title:

Text from PDF Page: 013

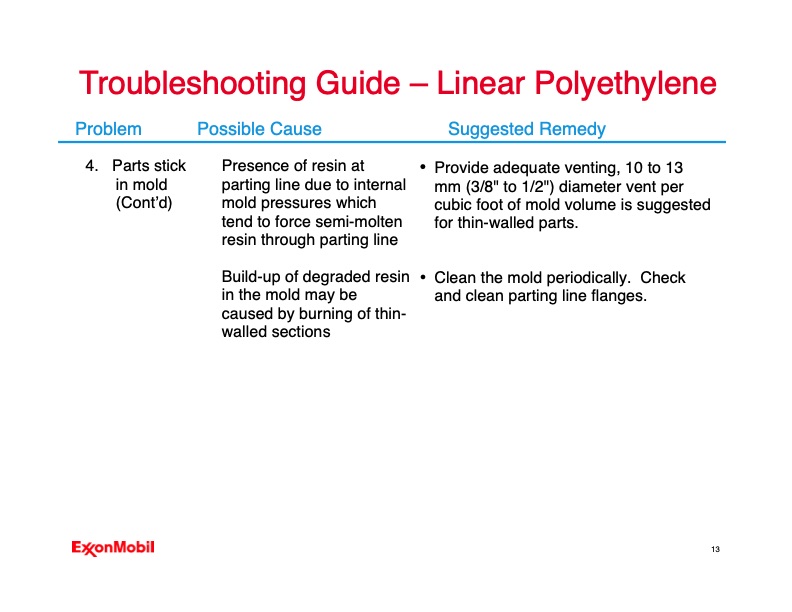

Troubleshooting Guide – Linear Polyethylene Problem Possible Cause Suggested Remedy 4. Parts stick in mold Presence of resin at parting line due to internal mold pressures which tend to force semi-molten resin through parting line • Provide adequate venting, 10 to 13 mm (3/8" to 1/2") diameter vent per cubic foot of mold volume is suggested for thin-walled parts. (Cont’d) Build-up of degraded resin • in the mold may be caused by burning of thin- walled sections Clean the mold periodically. Check and clean parting line flanges. 13PDF Image | Troubleshooting your rotomolding operation

PDF Search Title:

Troubleshooting your rotomolding operationOriginal File Name Searched:

cooke.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |