PDF Publication Title:

Text from PDF Page: 011

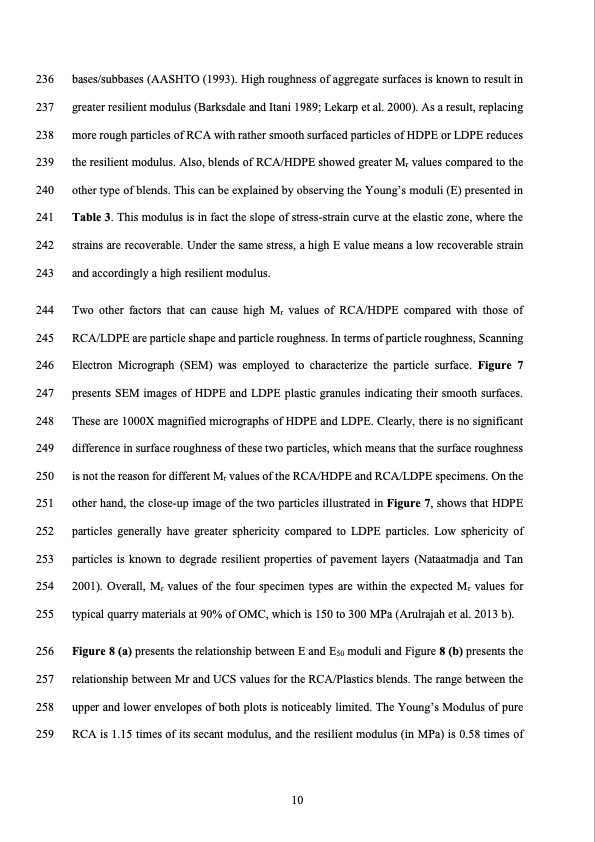

236 bases/subbases (AASHTO (1993). High roughness of aggregate surfaces is known to result in 237 greater resilient modulus (Barksdale and Itani 1989; Lekarp et al. 2000). As a result, replacing 238 more rough particles of RCA with rather smooth surfaced particles of HDPE or LDPE reduces 239 the resilient modulus. Also, blends of RCA/HDPE showed greater Mr values compared to the 240 other type of blends. This can be explained by observing the Young’s moduli (E) presented in 241 Table 3. This modulus is in fact the slope of stress-strain curve at the elastic zone, where the 242 strains are recoverable. Under the same stress, a high E value means a low recoverable strain 243 and accordingly a high resilient modulus. 244 Two other factors that can cause high Mr values of RCA/HDPE compared with those of 245 RCA/LDPE are particle shape and particle roughness. In terms of particle roughness, Scanning 246 Electron Micrograph (SEM) was employed to characterize the particle surface. Figure 7 247 presents SEM images of HDPE and LDPE plastic granules indicating their smooth surfaces. 248 These are 1000X magnified micrographs of HDPE and LDPE. Clearly, there is no significant 249 difference in surface roughness of these two particles, which means that the surface roughness 250 is not the reason for different Mr values of the RCA/HDPE and RCA/LDPE specimens. On the 251 other hand, the close-up image of the two particles illustrated in Figure 7, shows that HDPE 252 particles generally have greater sphericity compared to LDPE particles. Low sphericity of 253 particles is known to degrade resilient properties of pavement layers (Nataatmadja and Tan 254 2001). Overall, Mr values of the four specimen types are within the expected Mr values for 255 typical quarry materials at 90% of OMC, which is 150 to 300 MPa (Arulrajah et al. 2013 b). 256 Figure 8 (a) presents the relationship between E and E50 moduli and Figure 8 (b) presents the 257 relationship between Mr and UCS values for the RCA/Plastics blends. The range between the 258 upper and lower envelopes of both plots is noticeably limited. The Young’s Modulus of pure 259 RCA is 1.15 times of its secant modulus, and the resilient modulus (in MPa) is 0.58 times of 10PDF Image | Stiffness Properties of Recycled Concrete Aggregate with Polyethylene Plastic Granules

PDF Search Title:

Stiffness Properties of Recycled Concrete Aggregate with Polyethylene Plastic GranulesOriginal File Name Searched:

Ep38221_Stiffness-Properties.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |