PDF Publication Title:

Text from PDF Page: 006

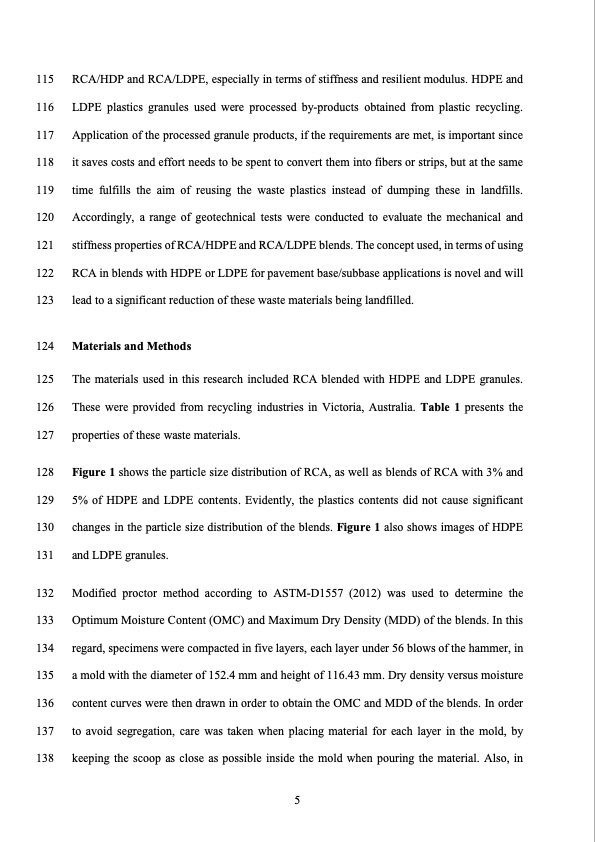

115 RCA/HDP and RCA/LDPE, especially in terms of stiffness and resilient modulus. HDPE and 116 LDPE plastics granules used were processed by-products obtained from plastic recycling. 117 Application of the processed granule products, if the requirements are met, is important since 118 it saves costs and effort needs to be spent to convert them into fibers or strips, but at the same 119 time fulfills the aim of reusing the waste plastics instead of dumping these in landfills. 120 Accordingly, a range of geotechnical tests were conducted to evaluate the mechanical and 121 stiffness properties of RCA/HDPE and RCA/LDPE blends. The concept used, in terms of using 122 RCA in blends with HDPE or LDPE for pavement base/subbase applications is novel and will 123 lead to a significant reduction of these waste materials being landfilled. 124 Materials and Methods 125 The materials used in this research included RCA blended with HDPE and LDPE granules. 126 These were provided from recycling industries in Victoria, Australia. Table 1 presents the 127 properties of these waste materials. 128 Figure 1 shows the particle size distribution of RCA, as well as blends of RCA with 3% and 129 5% of HDPE and LDPE contents. Evidently, the plastics contents did not cause significant 130 changes in the particle size distribution of the blends. Figure 1 also shows images of HDPE 131 and LDPE granules. 132 Modified proctor method according to ASTM-D1557 (2012) was used to determine the 133 Optimum Moisture Content (OMC) and Maximum Dry Density (MDD) of the blends. In this 134 regard, specimens were compacted in five layers, each layer under 56 blows of the hammer, in 135 a mold with the diameter of 152.4 mm and height of 116.43 mm. Dry density versus moisture 136 content curves were then drawn in order to obtain the OMC and MDD of the blends. In order 137 to avoid segregation, care was taken when placing material for each layer in the mold, by 138 keeping the scoop as close as possible inside the mold when pouring the material. Also, in 5PDF Image | Stiffness Properties of Recycled Concrete Aggregate with Polyethylene Plastic Granules

PDF Search Title:

Stiffness Properties of Recycled Concrete Aggregate with Polyethylene Plastic GranulesOriginal File Name Searched:

Ep38221_Stiffness-Properties.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |