PDF Publication Title:

Text from PDF Page: 016

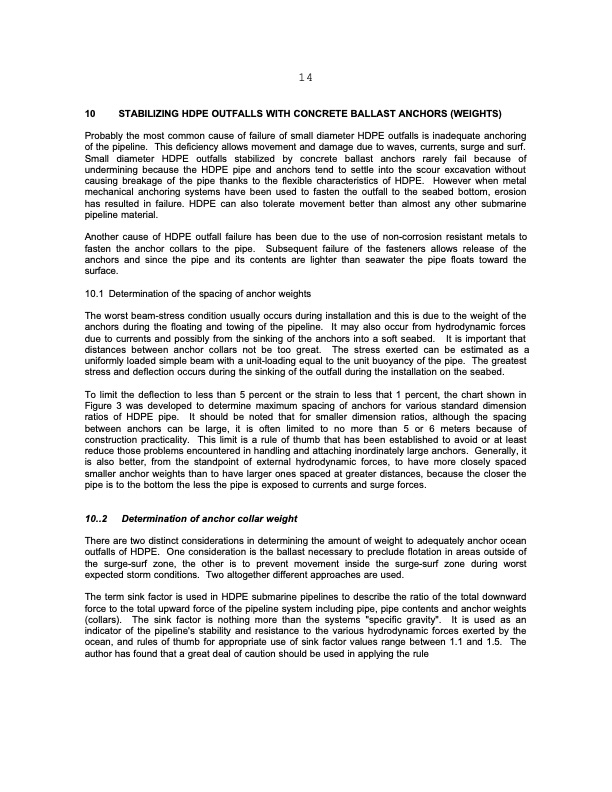

14 10 STABILIZING HDPE OUTFALLS WITH CONCRETE BALLAST ANCHORS (WEIGHTS) Probably the most common cause of failure of small diameter HDPE outfalls is inadequate anchoring of the pipeline. This deficiency allows movement and damage due to waves, currents, surge and surf. Small diameter HDPE outfalls stabilized by concrete ballast anchors rarely fail because of undermining because the HDPE pipe and anchors tend to settle into the scour excavation without causing breakage of the pipe thanks to the flexible characteristics of HDPE. However when metal mechanical anchoring systems have been used to fasten the outfall to the seabed bottom, erosion has resulted in failure. HDPE can also tolerate movement better than almost any other submarine pipeline material. Another cause of HDPE outfall failure has been due to the use of non-corrosion resistant metals to fasten the anchor collars to the pipe. Subsequent failure of the fasteners allows release of the anchors and since the pipe and its contents are lighter than seawater the pipe floats toward the surface. 10.1 Determination of the spacing of anchor weights The worst beam-stress condition usually occurs during installation and this is due to the weight of the anchors during the floating and towing of the pipeline. It may also occur from hydrodynamic forces due to currents and possibly from the sinking of the anchors into a soft seabed. It is important that distances between anchor collars not be too great. The stress exerted can be estimated as a uniformly loaded simple beam with a unit-loading equal to the unit buoyancy of the pipe. The greatest stress and deflection occurs during the sinking of the outfall during the installation on the seabed. To limit the deflection to less than 5 percent or the strain to less that 1 percent, the chart shown in Figure 3 was developed to determine maximum spacing of anchors for various standard dimension ratios of HDPE pipe. It should be noted that for smaller dimension ratios, although the spacing between anchors can be large, it is often limited to no more than 5 or 6 meters because of construction practicality. This limit is a rule of thumb that has been established to avoid or at least reduce those problems encountered in handling and attaching inordinately large anchors. Generally, it is also better, from the standpoint of external hydrodynamic forces, to have more closely spaced smaller anchor weights than to have larger ones spaced at greater distances, because the closer the pipe is to the bottom the less the pipe is exposed to currents and surge forces. 10..2 Determination of anchor collar weight There are two distinct considerations in determining the amount of weight to adequately anchor ocean outfalls of HDPE. One consideration is the ballast necessary to preclude flotation in areas outside of the surge-surf zone, the other is to prevent movement inside the surge-surf zone during worst expected storm conditions. Two altogether different approaches are used. The term sink factor is used in HDPE submarine pipelines to describe the ratio of the total downward force to the total upward force of the pipeline system including pipe, pipe contents and anchor weights (collars). The sink factor is nothing more than the systems "specific gravity". It is used as an indicator of the pipeline's stability and resistance to the various hydrodynamic forces exerted by the ocean, and rules of thumb for appropriate use of sink factor values range between 1.1 and 1.5. The author has found that a great deal of caution should be used in applying the rulePDF Image | SMALL DIAMETER (HDPE) SUBMARINE OUTFALLS

PDF Search Title:

SMALL DIAMETER (HDPE) SUBMARINE OUTFALLSOriginal File Name Searched:

OPSCEPISPUB0060_eng.PDFDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |