PDF Publication Title:

Text from PDF Page: 002

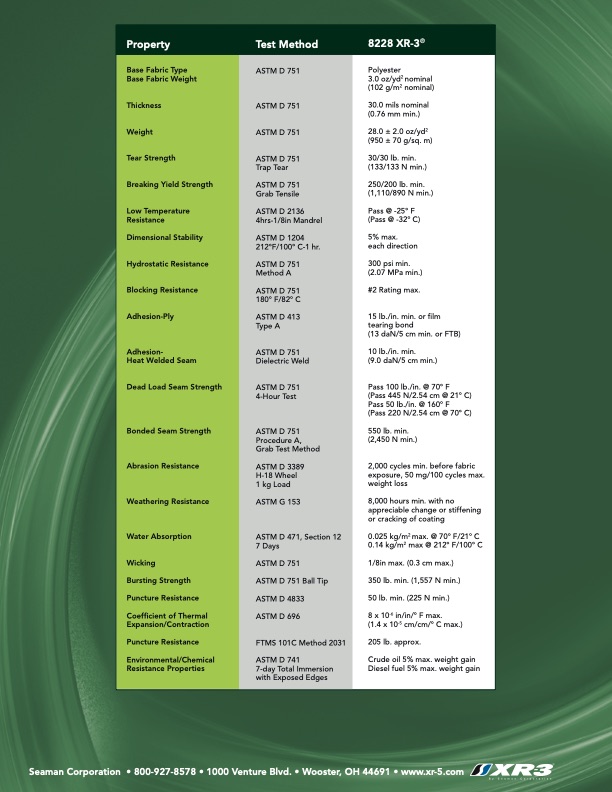

Property Test Method 8228 XR-3® Base Fabric Type Base Fabric Weight Thickness Weight Tear Strength Breaking Yield Strength Low Temperature Resistance Dimensional Stability Hydrostatic Resistance Blocking Resistance Adhesion-Ply Adhesion- Heat Welded Seam Dead Load Seam Strength Bonded Seam Strength Abrasion Resistance Weathering Resistance Water Absorption Wicking Bursting Strength Puncture Resistance Coefficient of Thermal Expansion/Contraction Puncture Resistance Environmental/Chemical Resistance Properties ASTM D 751 ASTM D 751 ASTM D 751 ASTM D 751 Trap Tear ASTM D 751 Grab Tensile ASTM D 2136 4hrs-1/8in Mandrel ASTM D 1204 212oF/100o C-1 hr. ASTM D 751 Method A ASTM D 751 180o F/82o C ASTM D 413 Type A ASTM D 751 Dielectric Weld ASTM D 751 4-Hour Test ASTM D 751 Procedure A, Grab Test Method ASTM D 3389 H-18 Wheel 1 kg Load ASTM G 153 ASTM D 471, Section 12 7 Days ASTM D 751 ASTM D 751 Ball Tip ASTM D 4833 ASTM D 696 FTMS 101C Method 2031 ASTM D 741 7-day Total Immersion with Exposed Edges Polyester 3.0 oz/yd2 nominal (102 g/m2 nominal) 30.0 mils nominal (0.76 mm min.) 28.0 ± 2.0 oz/yd2 (950 ± 70 g/sq. m) 30/30 lb. min. (133/133 N min.) 250/200 lb. min. (1,110/890 N min.) Pass @ -25o F (Pass @ -32o C) 5% max. each direction 300 psi min. (2.07 MPa min.) #2 Rating max. 15 lb./in. min. or film tearing bond (13 daN/5 cm min. or FTB) 10 lb./in. min. (9.0 daN/5 cm min.) Pass 100 lb./in. @ 70o F (Pass 445 N/2.54 cm @ 21o C) Pass 50 lb./in. @ 160o F (Pass 220 N/2.54 cm @ 70o C) 550 lb. min. (2,450 N min.) 2,000 cycles min. before fabric exposure, 50 mg/100 cycles max. weight loss 8,000 hours min. with no appreciable change or stiffening or cracking of coating 0.025 kg/m2 max. @ 70o F/21o C 0.14 kg/m2 max @ 212o F/100o C 1/8in max. (0.3 cm max.) 350 lb. min. (1,557 N min.) 50 lb. min. (225 N min.) 8 x 10-6 in/in/o F max. (1.4 x 10-5 cm/cm/o C max.) 205 lb. approx. Crude oil 5% max. weight gain Diesel fuel 5% max. weight gain Seaman Corporation • 800-927-8578 • 1000 Venture Blvd. • Wooster, OH 44691 • www.xr-5.comPDF Image | Seaman Corporation developed XR-3

PDF Search Title:

Seaman Corporation developed XR-3Original File Name Searched:

8228-specs.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |