PDF Publication Title:

Text from PDF Page: 018

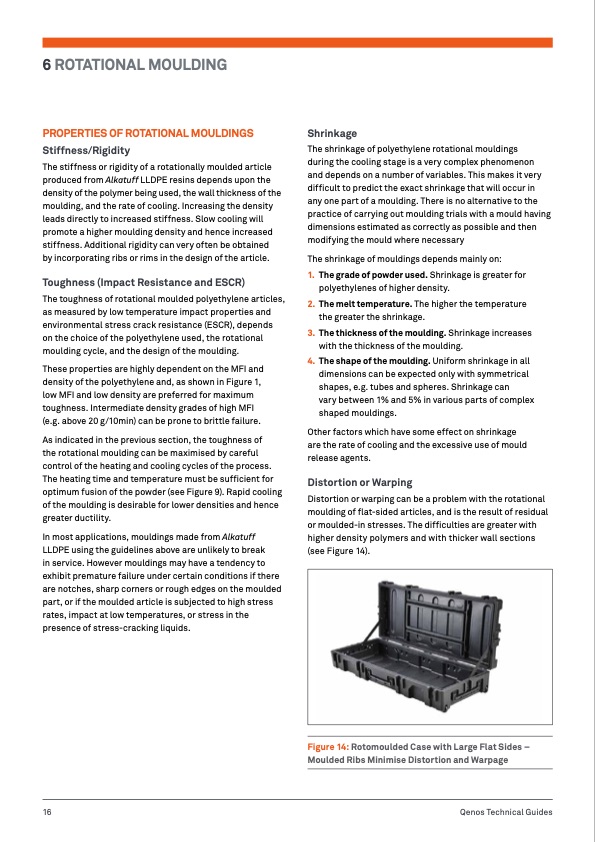

6 ROTATIONAL MOULDING PROPERTIES OF ROTATIONAL MOULDINGS Stiffness/Rigidity The stiffness or rigidity of a rotationally moulded article produced from Alkatuff LLDPE resins depends upon the density of the polymer being used, the wall thickness of the moulding, and the rate of cooling. Increasing the density leads directly to increased stiffness. Slow cooling will promote a higher moulding density and hence increased stiffness. Additional rigidity can very often be obtained by incorporating ribs or rims in the design of the article. Toughness (Impact Resistance and ESCR) The toughness of rotational moulded polyethylene articles, as measured by low temperature impact properties and environmental stress crack resistance (ESCR), depends on the choice of the polyethylene used, the rotational moulding cycle, and the design of the moulding. These properties are highly dependent on the MFI and density of the polyethylene and, as shown in Figure 1, low MFI and low density are preferred for maximum toughness. Intermediate density grades of high MFI (e.g. above 20 g/10min) can be prone to brittle failure. As indicated in the previous section, the toughness of the rotational moulding can be maximised by careful control of the heating and cooling cycles of the process. The heating time and temperature must be sufficient for optimum fusion of the powder (see Figure 9). Rapid cooling of the moulding is desirable for lower densities and hence greater ductility. In most applications, mouldings made from Alkatuff LLDPE using the guidelines above are unlikely to break in service. However mouldings may have a tendency to exhibit premature failure under certain conditions if there are notches, sharp corners or rough edges on the moulded part, or if the moulded article is subjected to high stress rates, impact at low temperatures, or stress in the presence of stress-cracking liquids. Shrinkage The shrinkage of polyethylene rotational mouldings during the cooling stage is a very complex phenomenon and depends on a number of variables. This makes it very difficult to predict the exact shrinkage that will occur in any one part of a moulding. There is no alternative to the practice of carrying out moulding trials with a mould having dimensions estimated as correctly as possible and then modifying the mould where necessary The shrinkage of mouldings depends mainly on: 1. Thegradeofpowderused.Shrinkageisgreaterfor polyethylenes of higher density. 2. The melt temperature. The higher the temperature the greater the shrinkage. 3. The thickness of the moulding. Shrinkage increases with the thickness of the moulding. 4. The shape of the moulding. Uniform shrinkage in all dimensions can be expected only with symmetrical shapes, e.g. tubes and spheres. Shrinkage can vary between 1% and 5% in various parts of complex shaped mouldings. Other factors which have some effect on shrinkage are the rate of cooling and the excessive use of mould release agents. Distortion or Warping Distortion or warping can be a problem with the rotational moulding of flat-sided articles, and is the result of residual or moulded-in stresses. The difficulties are greater with higher density polymers and with thicker wall sections (see Figure 14). Figure 14: Rotomoulded Case with Large Flat Sides – Moulded Ribs Minimise Distortion and Warpage 16 Qenos Technical GuidesPDF Image | ROTATIONAL MOULDING Guide

PDF Search Title:

ROTATIONAL MOULDING GuideOriginal File Name Searched:

TG6Roto.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |