PDF Publication Title:

Text from PDF Page: 011

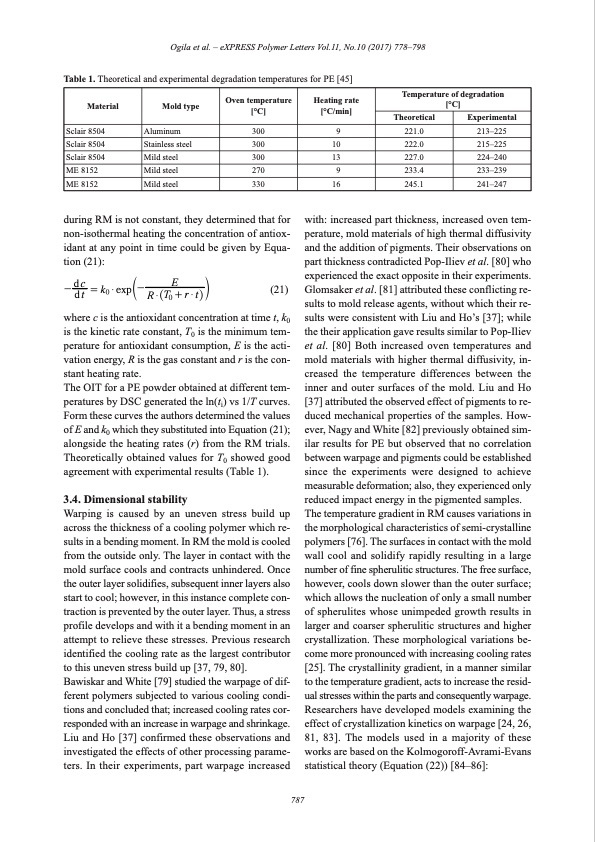

Ogila et al. – eXPRESS Polymer Letters Vol.11, No.10 (2017) 778–798 Table 1. Theoretical and experimental degradation temperatures for PE [45] Material Mold type Oven temperature [°C] Heating rate [°C/min] Temperature of degradation [°C] Theoretical Experimental Sclair 8504 Aluminum 300 9 221.0 213–225 Sclair 8504 Stainless steel 300 10 222.0 215–225 Sclair 8504 Mild steel 300 13 227.0 224–240 ME 8152 Mild steel 270 9 233.4 233–239 ME 8152 Mild steel 330 16 245.1 241–247 during RM is not constant, they determined that for non-isothermal heating the concentration of antiox- idant at any point in time could be given by Equa- tion (21): with: increased part thickness, increased oven tem- perature, mold materials of high thermal diffusivity and the addition of pigments. Their observations on part thickness contradicted Pop-Iliev et al. [80] who experienced the exact opposite in their experiments. Glomsaker et al. [81] attributed these conflicting re- sults to mold release agents, without which their re- sults were consistent with Liu and Ho’s [37]; while the their application gave results similar to Pop-Iliev et al. [80] Both increased oven temperatures and mold materials with higher thermal diffusivity, in- creased the temperature differences between the inner and outer surfaces of the mold. Liu and Ho [37] attributed the observed effect of pigments to re- duced mechanical properties of the samples. How- ever, Nagy and White [82] previously obtained sim- ilar results for PE but observed that no correlation between warpage and pigments could be established since the experiments were designed to achieve measurable deformation; also, they experienced only reduced impact energy in the pigmented samples. The temperature gradient in RM causes variations in the morphological characteristics of semi-crystalline polymers [76]. The surfaces in contact with the mold wall cool and solidify rapidly resulting in a large number of fine spherulitic structures. The free surface, however, cools down slower than the outer surface; which allows the nucleation of only a small number of spherulites whose unimpeded growth results in larger and coarser spherulitic structures and higher crystallization. These morphological variations be- come more pronounced with increasing cooling rates [25]. The crystallinity gradient, in a manner similar to the temperature gradient, acts to increase the resid- ual stresses within the parts and consequently warpage. Researchers have developed models examining the effect of crystallization kinetics on warpage [24, 26, 81, 83]. The models used in a majority of these works are based on the Kolmogoroff-Avrami-Evans statistical theory (Equation (22)) [84–86]: dc E -dt =k0$expT-R$RT +r$tWY 0 (21) where c is the antioxidant concentration at time t, k0 is the kinetic rate constant, T0 is the minimum tem- perature for antioxidant consumption, E is the acti- vation energy, R is the gas constant and r is the con- stant heating rate. The OIT for a PE powder obtained at different tem- peratures by DSC generated the ln(ti) vs 1/T curves. Form these curves the authors determined the values of E and k0 which they substituted into Equation (21); alongside the heating rates (r) from the RM trials. Theoretically obtained values for T0 showed good agreement with experimental results (Table 1). 3.4. Dimensional stability Warping is caused by an uneven stress build up across the thickness of a cooling polymer which re- sults in a bending moment. In RM the mold is cooled from the outside only. The layer in contact with the mold surface cools and contracts unhindered. Once the outer layer solidifies, subsequent inner layers also start to cool; however, in this instance complete con- traction is prevented by the outer layer. Thus, a stress profile develops and with it a bending moment in an attempt to relieve these stresses. Previous research identified the cooling rate as the largest contributor to this uneven stress build up [37, 79, 80]. Bawiskar and White [79] studied the warpage of dif- ferent polymers subjected to various cooling condi- tions and concluded that; increased cooling rates cor- responded with an increase in warpage and shrinkage. Liu and Ho [37] confirmed these observations and investigated the effects of other processing parame- ters. In their experiments, part warpage increased 787PDF Image | Rotational molding: A review

PDF Search Title:

Rotational molding: A reviewOriginal File Name Searched:

Rotational_molding_A_review_of_the_models_and_mate.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |