PDF Publication Title:

Text from PDF Page: 003

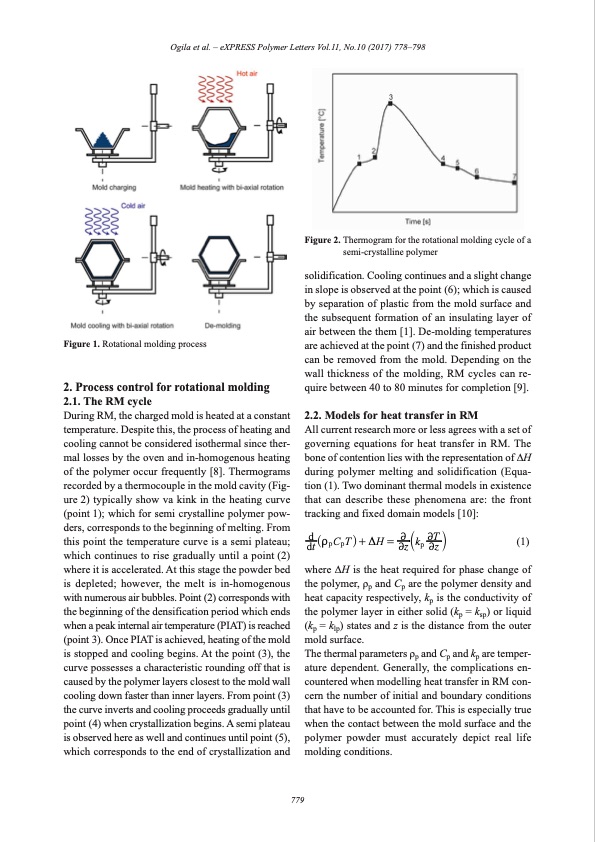

Ogila et al. – eXPRESS Polymer Letters Vol.11, No.10 (2017) 778–798 Figure 1. Rotational molding process 2. Process control for rotational molding 2.1. The RM cycle During RM, the charged mold is heated at a constant temperature. Despite this, the process of heating and cooling cannot be considered isothermal since ther- mal losses by the oven and in-homogenous heating of the polymer occur frequently [8]. Thermograms recorded by a thermocouple in the mold cavity (Fig- ure 2) typically show va kink in the heating curve (point 1); which for semi crystalline polymer pow- ders, corresponds to the beginning of melting. From this point the temperature curve is a semi plateau; which continues to rise gradually until a point (2) where it is accelerated. At this stage the powder bed is depleted; however, the melt is in-homogenous with numerous air bubbles. Point (2) corresponds with the beginning of the densification period which ends when a peak internal air temperature (PIAT) is reached (point 3). Once PIAT is achieved, heating of the mold is stopped and cooling begins. At the point (3), the curve possesses a characteristic rounding off that is caused by the polymer layers closest to the mold wall cooling down faster than inner layers. From point (3) the curve inverts and cooling proceeds gradually until point (4) when crystallization begins. A semi plateau is observed here as well and continues until point (5), which corresponds to the end of crystallization and Figure 2. Thermogram for the rotational molding cycle of a semi-crystalline polymer solidification. Cooling continues and a slight change in slope is observed at the point (6); which is caused by separation of plastic from the mold surface and the subsequent formation of an insulating layer of air between the them [1]. De-molding temperatures are achieved at the point (7) and the finished product can be removed from the mold. Depending on the wall thickness of the molding, RM cycles can re- quire between 40 to 80 minutes for completion [9]. 2.2. Models for heat transfer in RM All current research more or less agrees with a set of governing equations for heat transfer in RM. The bone of contention lies with the representation of ∆H during polymer melting and solidification (Equa- tion (1). Two dominant thermal models in existence that can describe these phenomena are: the front tracking and fixed domain models [10]: d 22T dtRtpCpTW+DH=2zTkp 2zY (1) where ∆H is the heat required for phase change of the polymer, ρp and Cp are the polymer density and heat capacity respectively, kp is the conductivity of the polymer layer in either solid (kp = ksp) or liquid (kp = klp) states and z is the distance from the outer mold surface. The thermal parameters ρp and Cp and kp are temper- ature dependent. Generally, the complications en- countered when modelling heat transfer in RM con- cern the number of initial and boundary conditions that have to be accounted for. This is especially true when the contact between the mold surface and the polymer powder must accurately depict real life molding conditions. 779PDF Image | Rotational molding: A review

PDF Search Title:

Rotational molding: A reviewOriginal File Name Searched:

Rotational_molding_A_review_of_the_models_and_mate.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |