PDF Publication Title:

Text from PDF Page: 004

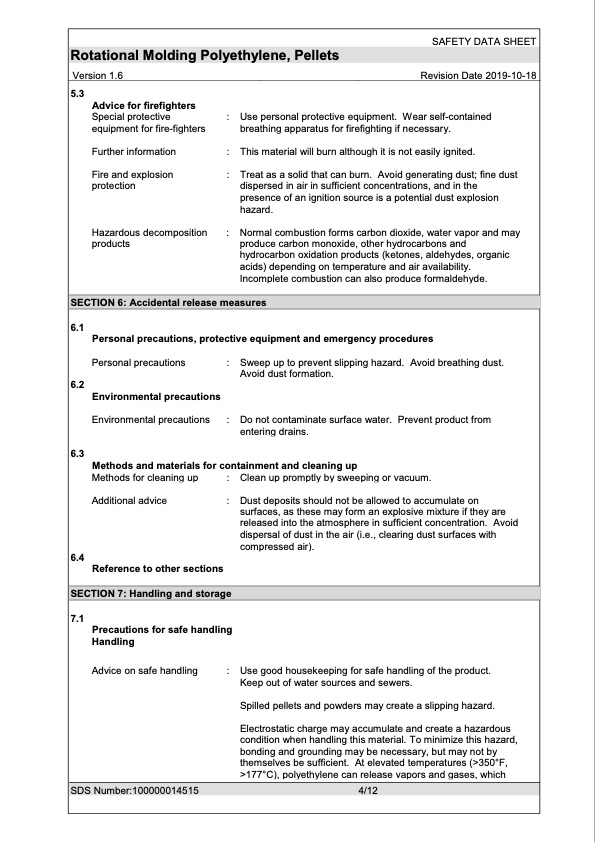

SAFETY DATA SHEET Rotational Molding Polyethylene, Pellets Version 1.6 Revision Date 2019-10-18 5.3 Advice for firefighters Special protective equipment for fire-fighters Further information Fire and explosion protection Hazardous decomposition products : Use personal protective equipment. Wear self-contained breathing apparatus for firefighting if necessary. : This material will burn although it is not easily ignited. : Treat as a solid that can burn. Avoid generating dust; fine dust dispersed in air in sufficient concentrations, and in the presence of an ignition source is a potential dust explosion hazard. : Normal combustion forms carbon dioxide, water vapor and may produce carbon monoxide, other hydrocarbons and hydrocarbon oxidation products (ketones, aldehydes, organic acids) depending on temperature and air availability. Incomplete combustion can also produce formaldehyde. SECTION 6: Accidental release measures 6.1 6.2 6.3 6.4 Personal precautions, protective equipment and emergency procedures Personal precautions : Environmental precautions Environmental precautions : Sweep up to prevent slipping hazard. Avoid breathing dust. Avoid dust formation. Do not contaminate surface water. Prevent product from entering drains. Methods and materials for containment and cleaning up Methods for cleaning up : Additional advice : Reference to other sections Clean up promptly by sweeping or vacuum. Dust deposits should not be allowed to accumulate on surfaces, as these may form an explosive mixture if they are released into the atmosphere in sufficient concentration. Avoid dispersal of dust in the air (i.e., clearing dust surfaces with compressed air). SECTION 7: Handling and storage 7.1 Precautions for safe handling Handling Advice on safe handling : Use good housekeeping for safe handling of the product. Keep out of water sources and sewers. Spilled pellets and powders may create a slipping hazard. Electrostatic charge may accumulate and create a hazardous condition when handling this material. To minimize this hazard, bonding and grounding may be necessary, but may not by themselves be sufficient. At elevated temperatures (>350°F, >177°C), polyethylene can release vapors and gases, which SDS Number:100000014515 4/12PDF Image | Rotational Molding Polyethylene Pellets

PDF Search Title:

Rotational Molding Polyethylene PelletsOriginal File Name Searched:

01543602_6.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |