PDF Publication Title:

Text from PDF Page: 003

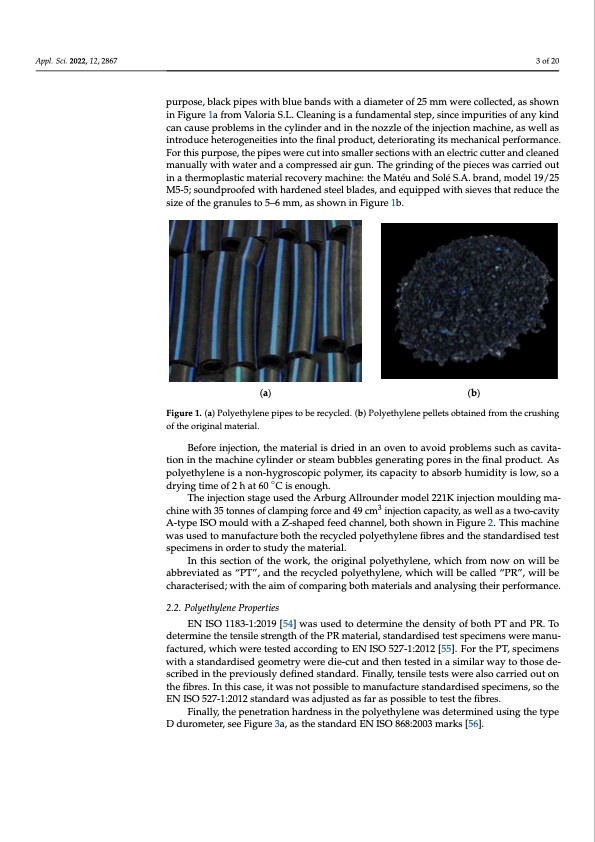

Appl. Sci. 2022, 12, 2867 2. Materials and Methods 2.1. Recycling Process The recycling process followed in this project consists of several steps: gatheri terial, cleaning, crushing, drying, and injection. The polymer selected for the work yethylene, specifically low-density polyethylene used in the industrial and const sectors. In this sense, the first measure is the collection of the thermoplastic. For th pose, black pipes with blue bands with a diameter of 25 mm were collected, as sh purpose, black pipes with blue bands with a diameter of 25 mm were collected, as shown Figure 1a from Valoria S.L. Cleaning is a fundamental step, since impurities of a in Figure 1a from Valoria S.L. Cleaning is a fundamental step, since impurities of any kind can cause problems in the cylinder and in the nozzle of the injection machine, as can cause problems in the cylinder and in the nozzle of the injection machine, as well as introduce heterogeneities into the final product, deteriorating its mechanical perfor introduce heterogeneities into the final product, deteriorating its mechanical performance. For this purpose, the pipes were cut into smaller sections with an electric cutt For this purpose, the pipes were cut into smaller sections with an electric cutter and cleaned cleaned manually with water and a compressed air gun. The grinding of the piec manually with water and a compressed air gun. The grinding of the pieces was carried out carried out in a thermoplastic material recovery machine: the Matéu and Solé S.A. 3 of 20 in a thermoplastic material recovery machine: the Matéu and Solé S.A. brand, model 19/25 model 19/25 M5-5; soundproofed with hardened steel blades, and equipped with M5-5; soundproofed with hardened steel blades, and equipped with sieves that reduce the that reduce the size of the granules to 5–6 mm, as shown in Figure 1b. size of the granules to 5–6 mm, as shown in Figure 1b. (a) (b) Figure 1. (a) Polyethylene pipes to be recycled. (b) Polyethylene pellets obtained from the c Figure 1. (a) Polyethylene pipes to be recycled. (b) Polyethylene pellets obtained from the crushing of the original material. of the original material. BeforeinjectionB,etfhoereminajtecrtiiaolni,sthderimedatienrianliosvdernietdoinavaonidovpernobtoleamvosisdupchroabslecmavsistua-chasca tion in the macihnintheecymliancdheinreocrysltienadmerbourbsbteleasmgebnuebrbalteisngepnoereastiingthpeorfiensainl ptrhoedfuincat.l Aprsoduct. A polyethylene iseathnyolenn-ehyisgaronsocno-phiycgprolsycmopeirc, pitoslcyampearc,iittystcoapaabcsiotyrbtohaubmsoidrbityhuismloidwit,ysoisalow, so a drying time of 2timh aeto6f02◦hCaits6e0no°Cugish.enough. TheinjectionstTagheuinsjedcttiohneAstrabguerugsAedllrtohuenAdrebrumrgoAdellr2o2u1nKdeinrjmecotidoenlm22o1uKldininjegctmioan-mouldi 3 chinewith35tocnhnienseowfcitlham3p5intognfnoersceoafncdla4m9pcmingifnojercetioandca4p9accimty,aisnwjecetliloansacatpwaoc-ictayv,iatyswellas 3 A-type ISO mocualvditwyiAth-taypZe-sIhSaOpemdofueleddwchitahnanZel-,sbhoatphedshfoeewdncihnaFningeul,rebo2t.hTshioswmnacinhiFniegure 2. T was used to macnhuinfaecwtuarseubsoetdhttohme raencuyfcalectdupreoblyoetthhtyhlenrecfiybclreds apnodlytehtheyslteanedfairbdreiseadntdestht e stand specimens in order to study the material. test specimens in order to study the material. In this section of the work, the original polyethylene, which from now on will be abbreviated as “PT”, and the recycled polyethylene, which will be called “PR”, will be characterised; with the aim of comparing both materials and analysing their performance. 2.2. Polyethylene Properties EN ISO 1183-1:2019 [54] was used to determine the density of both PT and PR. To determine the tensile strength of the PR material, standardised test specimens were manu- factured, which were tested according to EN ISO 527-1:2012 [55]. For the PT, specimens with a standardised geometry were die-cut and then tested in a similar way to those de- scribed in the previously defined standard. Finally, tensile tests were also carried out on the fibres. In this case, it was not possible to manufacture standardised specimens, so the EN ISO 527-1:2012 standard was adjusted as far as possible to test the fibres. Finally, the penetration hardness in the polyethylene was determined using the type D durometer, see Figure 3a, as the standard EN ISO 868:2003 marks [56]. n r o n w m r v n h aPDF Image | Recycled Polyethylene Fibres for Structural Concrete

PDF Search Title:

Recycled Polyethylene Fibres for Structural ConcreteOriginal File Name Searched:

applsci-12-02867.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |