PDF Publication Title:

Text from PDF Page: 005

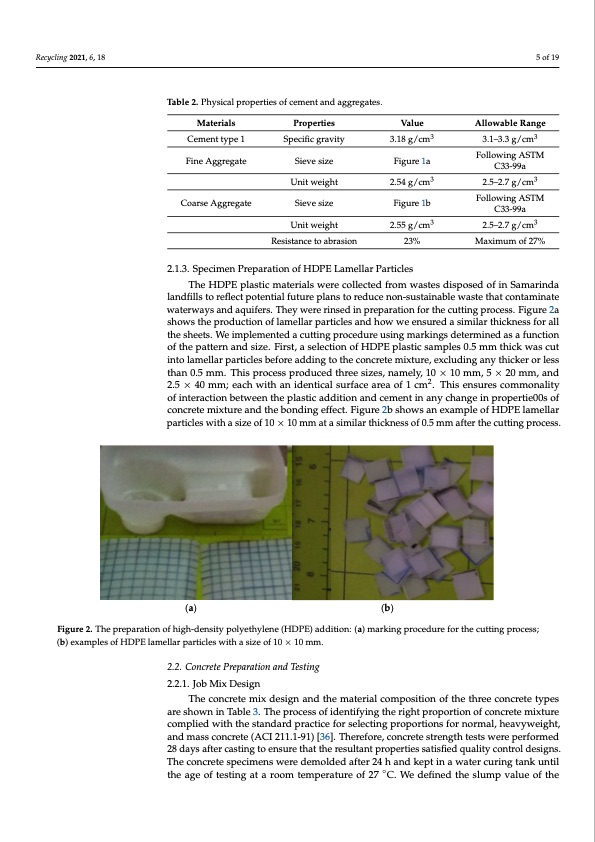

Recycling 2021, 6, 18 2021, 6, x FOR PEER REVIEW 5 of 19 Materials Cement type 1 Fine Aggregate oarse Aggregate Fine Aggregate Value 3.18 gU/cnmit weight Figure 1a Table 2. Physical properties of cement and aggregates. and a result of 23% was obtained. This value was lower than the 27% ASTM limit. Table Cement type 1 Specific gravity Table 2. Physical properties of cement and aggregates. Sieve size 3.18 g/cm3 Figure 1a 3.1–3.3 g/cm3 Following ASTM C33-99a 5 of 21 2 provides the detailedMphatyesricaalsl properties ofPtrhoepemrtaietesrials used for mViaxliuneg concrete. Allowable Range Properties Allowable Range Specific gravity Sieve size Unit weight Sieve size Unit weight Resistance to abrasion 3 33 3 Coarse Aggregate Sieve size 3.12–.354.3gg//cm Following ASTM C33-99a Figure 1b 2.5–2.7 g/cm3 2.5–2.7 g/cm Following ASTM C33-99a 2.5–2.7 g/cm3 Maximum of 27% 2.1.3. Specimen Preparation of HDPE Lamellar Particles 2.1.3. Specimen Preparation of HDPE Lamellar Particles 2.54 g/cm3 Figure 1b Following ASTM C33-99a 2.55 g/cm3 2.5–2.7 g/cm3 Unit weight 2.55 g/cm3 Resistance to abrasion 23% 23% Maximum of 27% The HDPE plastic materials were collected from wastes disposed of in Samarinda The HDPE plastic materials were collected from wastes disposed of in Samarinda landfills to reflect potential future plans to reduce non-sustainable waste that contaminate landfills to reflect potential future plans to reduce non-sustainable waste that contaminate waterways and aquifers. They were rinsed in preparation for the cutting process. Figure 2a waterways and aquifers. They were rinsed in preparation for the cutting process. Figure shows the production of lamellar particles and how we ensured a similar thickness for all 2a shows the production of lamellar particles and how we ensured a similar thickness for the sheets. We implemented a cutting procedure using markings determined as a function all the sheets. We implemented a cutting procedure using markings determined as a func- of the pattern and size. First, a selection of HDPE plastic samples 0.5 mm thick was cut tion of the pattern and size. First, a selection of HDPE plastic samples 0.5 mm thick was into lamellar particles before adding to the concrete mixture, excluding any thicker or less cut into lamellar particles before adding to the concrete mixture, excluding any thicker or than 0.5 mm. This process produced three sizes, namely, 10 × 10 mm, 5 × 20 mm, and less than 0.5 mm. This process produced three sizes, namely, 10 × 10 mm, 5 × 20 mm, and 2.5 × 40 mm; each with an identical surface area of 1 cm2. This ensures commonality 2.5 × 40 mm; each with an identical surface area of 1 cm2. This ensures commonality of of interaction between the plastic addition and cement in any change in propertie00s of interaction between the plastic addition and cement in any change in propertie00s of con- concrete mixture and the bonding effect. Figure 2b shows an example of HDPE lamellar crete mixture and the bonding effect. Figure 2b shows an example of HDPE lamellar par- particles with a size of 10 × 10 mm at a similar thickness of 0.5 mm after the cutting process. ticles with a size of 10 × 10 mm at a similar thickness of 0.5 mm after the cutting process. (a) (b) Figure 2. The preparation of high-density polyethylene (HDPE) addition: (a) marking procedure Figure 2. The preparation of high-density polyethylene (HDPE) addition: (a) marking procedure for the cutting process; for the cutting process; (b) examples of HDPE lamellar particles with a size of 10 × 10 mm. (b) examples of HDPE lamellar particles with a size of 10 × 10 mm. 2.2. Concrete Preparation and Testing 2.2.1. Job Mix Design 2.2. Concrete Preparation and Testing 2.2.1. Job Mix Design The concrete mix design and the material composition of the three concrete types are The concrete mix design and the material composition of the three concrete types shown in Table 3. The process of identifying the right proportion of concrete mixture com- are shown in Table 3. The process of identifying the right proportion of concrete mixture plied with the standard practice for selecting proportions for normal, heavyweight, and complied with the standard practice for selecting proportions for normal, heavyweight, mass concrete (ACI 211.1-91) [36]. Therefore, concrete strength tests were performed 28 and mass concrete (ACI 211.1-91) [36]. Therefore, concrete strength tests were performed days after casting to ensure that the resultant properties satisfied quality control designs. 28 days after casting to ensure that the resultant properties satisfied quality control designs. The concrete specimens were demolded after 24 h and kept in a water curing tank until The concrete specimens were demolded after 24 h and kept in a water curing tank until the age of testing at a room temperature of 27 °C. We defined the ◦slump value of the mix- the age of testing at a room temperature of 27 C. We defined the slump value of the ture for the three different concrete classes at the same range so it met cost efficiency and CPDF Image | Recycled HDPE Plastic Additions on Concrete Performance

PDF Search Title:

Recycled HDPE Plastic Additions on Concrete PerformanceOriginal File Name Searched:

recycling-06-00018-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |