PDF Publication Title:

Text from PDF Page: 005

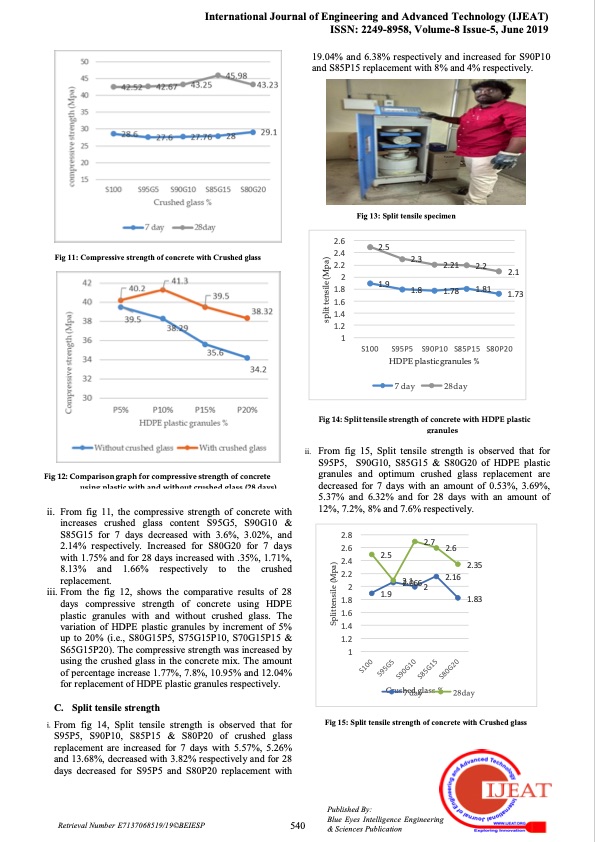

Fig 11: Compressive strength of concrete with Crushed glass ii. From fig 11, the compressive strength of concrete with increases crushed glass content S95G5, S90G10 & S85G15 for 7 days decreased with 3.6%, 3.02%, and 2.14% respectively. Increased for S80G20 for 7 days with 1.75% and for 28 days increased with .35%, 1.71%, 8.13% and 1.66% respectively to the crushed replacement. C. Split tensile strength i. From fig 14, Split tensile strength is observed that for S95P5, S90P10, S85P15 & S80P20 of crushed glass replacement are increased for 7 days with 5.57%, 5.26% and 13.68%, decreased with 3.82% respectively and for 28 days decreased for S95P5 and S80P20 replacement with Retrieval Number E7137068519/19©BEIESP 540 Fig 15: Split tensile strength of concrete with Crushed glass Published By: Blue Eyes Intelligence Engineering & Sciences Publication International Journal of Engineering and Advanced Technology (IJEAT) ISSN: 2249-8958, Volume-8 Issue-5, June 2019 19.04% and 6.38% respectively and increased for S90P10 and S85P15 replacement with 8% and 4% respectively. Fig 13: Split tensile specimen 2.6 2.5 2.4 2.3 2.2 2.21 2.2 2.1 1.73 2 1.9 1.8 1.8 1.6 1.4 1.2 1.78 1.81 1 S100 S95P5 S90P10 S85P15 S80P20 HDPE plastic granules % 7 day 28day Fig 14: Split tensile strength of concrete with HDPE plastic granules ii. From fig 15, Split tensile strength is observed that for S95P5, S90G10, S85G15 & S80G20 of HDPE plastic granules and optimum crushed glass replacement are decreased for 7 days with an amount of 0.53%, 3.69%, 5.37% and 6.32% and for 28 days with an amount of 12%, 7.2%, 8% and 7.6% respectively. Fig 12: Comparison graph for compressive strength of concrete using plastic with and without crushed glass (28 days) 2.8 2.6 2.4 2.2 2 1.8 1.6 1.4 1.2 1 2.7 2.5 2.6 2.1 2.0662 1.9 2.35 2.16 1.83 28day Crushed glass % 7 day iii. From the fig 12, shows the comparative results of 28 days compressive strength of concrete using HDPE plastic granules with and without crushed glass. The variation of HDPE plastic granules by increment of 5% up to 20% (i.e., S80G15P5, S75G15P10, S70G15P15 & S65G15P20). The compressive strength was increased by using the crushed glass in the concrete mix. The amount of percentage increase 1.77%, 7.8%, 10.95% and 12.04% for replacement of HDPE plastic granules respectively. Split tensile (Mpa) split tensile (Mpa)PDF Image | Recycled HDPE Partial Substitute of fine Sand in Concrete

PDF Search Title:

Recycled HDPE Partial Substitute of fine Sand in ConcreteOriginal File Name Searched:

E7137068519.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |