PDF Publication Title:

Text from PDF Page: 014

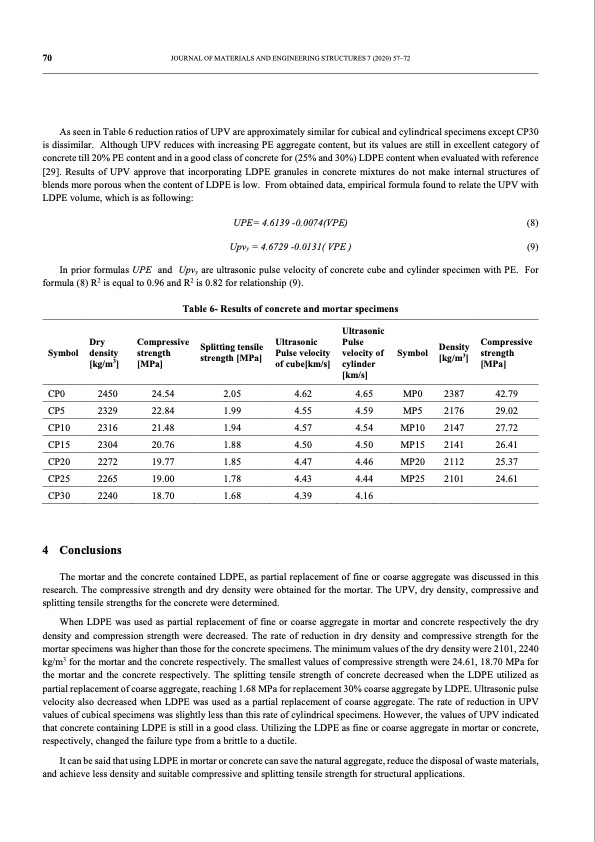

70 JOURNAL OF MATERIALS AND ENGINEERING STRUCTURES 7 (2020) 57–72 As seen in Table 6 reduction ratios of UPV are approximately similar for cubical and cylindrical specimens except CP30 is dissimilar. Although UPV reduces with increasing PE aggregate content, but its values are still in excellent category of concrete till 20% PE content and in a good class of concrete for (25% and 30%) LDPE content when evaluated with reference [29]. Results of UPV approve that incorporating LDPE granules in concrete mixtures do not make internal structures of blends more porous when the content of LDPE is low. From obtained data, empirical formula found to relate the UPV with LDPE volume, which is as following: UPE= 4.6139 -0.0074(VPE) (8) Upvy = 4.6729 -0.0131( VPE ) (9) In prior formulas UPE and Upvy are ultrasonic pulse velocity of concrete cube and cylinder specimen with PE. For formula (8) R2 is equal to 0.96 and R2 is 0.82 for relationship (9). Table 6- Results of concrete and mortar specimens Ultrasonic Pulse Density velocity of Symbol [kg/m3] cylinder [km/s] 4.65 MP0 2387 4.59 MP5 2176 4.54 MP10 2147 4.50 MP15 2141 4.46 MP20 2112 4.44 MP25 2101 4.16 The mortar and the concrete research. The compressive strength and dry density were obtained for the mortar. The UPV, dry density, compressive and splitting tensile strengths for the concrete were determined. When LDPE was used as partial replacement of fine or coarse aggregate in mortar and concrete respectively the dry density and compression strength were decreased. The rate of reduction in dry density and compressive strength for the mortar specimens was higher than those for the concrete specimens. The minimum values of the dry density were 2101, 2240 kg/m3 for the mortar and the concrete respectively. The smallest values of compressive strength were 24.61, 18.70 MPa for the mortar and the concrete respectively. The splitting tensile strength of concrete decreased when the LDPE utilized as partial replacement of coarse aggregate, reaching 1.68 MPa for replacement 30% coarse aggregate by LDPE. Ultrasonic pulse velocity also decreased when LDPE was used as a partial replacement of coarse aggregate. The rate of reduction in UPV values of cubical specimens was slightly less than this rate of cylindrical specimens. However, the values of UPV indicated that concrete containing LDPE is still in a good class. Utilizing the LDPE as fine or coarse aggregate in mortar or concrete, respectively, changed the failure type from a brittle to a ductile. It can be said that using LDPE in mortar or concrete can save the natural aggregate, reduce the disposal of waste materials, and achieve less density and suitable compressive and splitting tensile strength for structural applications. Dry Compressive Symbol density strength [kg/m3] [MPa] CP0 2450 24.54 CP5 2329 22.84 CP10 2316 21.48 CP15 2304 20.76 CP20 2272 19.77 CP25 2265 19.00 CP30 2240 18.70 4 Conclusions Splitting tensile strength [MPa] 2.05 1.99 1.94 1.88 1.85 1.78 1.68 Ultrasonic Pulse velocity of cube[km/s] 4.62 4.55 4.57 4.50 4.47 4.43 4.39 Compressive strength [MPa] 42.79 29.02 27.72 26.41 25.37 24.61 contained LDPE, as partial replacement of fine or coarse aggregate was discussed in thisPDF Image | Properties of Concrete and Mortar with LDPE Aggregate

PDF Search Title:

Properties of Concrete and Mortar with LDPE AggregateOriginal File Name Searched:

287224885.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |