PDF Publication Title:

Text from PDF Page: 041

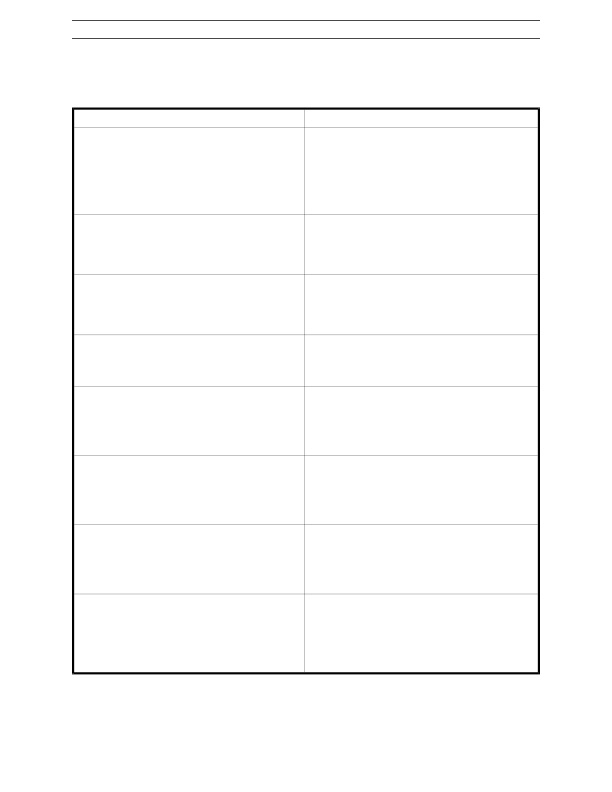

Naval Applications of Composites Marine Composites Table 1-2 Recent Submarine Research & Development Composites Programs Application Participants and Status Dry Deck Shelter The existing steel Dry Deck Shelter is composed of four major segments, the hyperbaric sphere which serves as a decompression chamber, the access sphere which permits access to the Hanger and to the hyperbaric sphere, the Hanger, which stores the Swimmer Delivery Vehicle, and the Hanger Door. The composite design has a joint in the middle of the hanger to test this critical technology. [1-27] General Dynamics EB Division is the overall design agent and is building the rear half of the Hanger of carbon/PEEK or PPS. Grumman Aerospace is building the Hanger Door; McDonnell Douglass Aircraft is building the Forward Hanger and Hyperbaric Sphere using PEEK and woven/braided/stitched glass/carbon preforms and a 4-foot diameter section has been built and tested to 120% design pressure; and Lockheed is building the Access Sphere from carbon/PEEK. Propulsion Shaft A thick-sectioned, filament wound tube was developed that resulted in a cost-effective, fatigue- resistant propulsion shaft. The section of the shaft between the first inboard coupling and the propeller will be tested in demonstrations aboard the Memphis . Brunswick Defense has filament wound a number of prototype shafts for testing, including a 3-inch thick, 3- foot diameter section. Concurrent programs are at NSWC, Annapolis for the Navy’s oiler fleet and training vessels under the guidance of Gene Camponeschi and George Wilhelmi. [1-28] Control Surfaces This demonstration focuses on hydrodynamically loaded structures, initially fairwater planes, to be tested on the Memphis . Construction employs a simple box spar for stiffness and syntactic foam cells to provide the correct hydrodynamic form. Newport News Shipbuilding recently completed the design, analysis, fabrication and testing of a control surface for a small submersible [1-33]. General Dynamics EB Division built all-composite diving planes for the NR-1 that included a carbon shaft that transitioned to a titanium post. Air Flasks This is a straightforward application aimed at weight reduction. Most of the sub-scale testing was completed under ONT technology block programs. The primary remaining issue is service life. Impetus for this program has waned somewhat as certification procedures for metal flasks have been updated and the location of the weight saved will not now appreciably improve the performance of the submarine. Engine Room Composites Applications The project goal was to develop generic design technology for machinery foundations and supports. The technology demonstrator is a 1/4-scale main propulsion engine subbase. This will be followed by a yet-to-be-selected full-scale application to demonstrate the technology. Westinghouse has built some prototype composite foundations, including one designed for a submarine main propulsion plant. Although superior damping characteristics can be achieved with composite structures, improved performance is not a given as structures need to be engineered based on stiffnesses and weights. Fire issues have put this effort on hold. Fairwater This demonstration involves a large, nonpressure-hull, hydrodynamic structure which, if built, would enhance ship stability through reduction of topside weight. Use of composites might also facilitate novel fairwater designs as might be required to accommodate new functions within the sail and to reduce wake. Currently under development, the design for a next generation fairwater will largely be dictated by mission requirement (size) and hydrodynamics (shape). Composites may offer the opportunity to improve functionality at reduced weight and cost. Stern Structure This demonstration, involving a large, nonpressure- hull, hydrodynamic structure would carry the fairwater demonstration a step further. It is expected to lead to the development of a structural �system� which will provide the basis for an all-composites outer hull for future designs. General Dynamics EB Division built a 1/10 scale model of a submarine stern section of glass/epoxy prepreg. The goal of the prototype was to demonstrate weight savings, maintenance reduction and acoustic and magnetic signature reduction. NSWC conducted �whipping� analysis and shock testing of the model. Bow Structure The Navy has long made use of composite materials for construction of bow domes that are structural yet allow for sonar transmission. These glass-epoxy structures are believed to be the world’s largest autoclave-cured parts. More recently developed is a complete bow section of the NR-1 research submarine. The bow dome development program was undertaken by HITCO. In 1986, HITCO completed a rigorous test program to qualify impact resistant epoxy prepreg systems. [1-29]. An extensive composite bow section of the NR-1 was built by Lunn. 28PDF Image | Marine Componsites

PDF Search Title:

Marine ComponsitesOriginal File Name Searched:

MARINE_COMPOSITES.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |