PDF Publication Title:

Text from PDF Page: 020

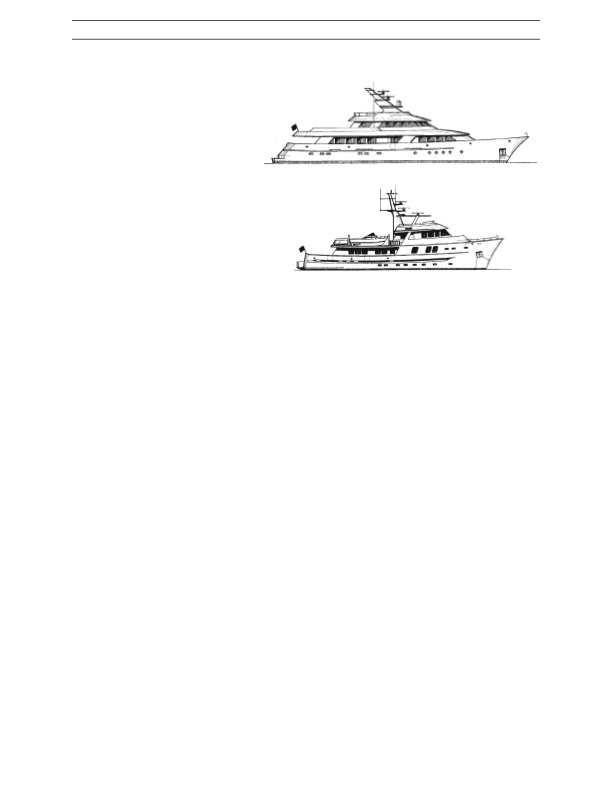

Chapter One APPLICATIONS Examples of their 131-foot and 105-foot semi-displacement yachts are shown in Figure 1-8. They currently have a 150-foot design under construction. Charter vessels for sightseeing and fishing are also built using single-skin hull construction. Hull sides, decks and deckhouses are balsa cored. Delta employs up to 200 skilled craftsman and an engineering staff of 10 to build on a semi-custom basis using adjustable female hull molds. Characteristic of Delta-built motor yachts is a bulbous bow, more often Figure 1-8 found on large ships to improve acht and 105’ Deep-Sea Motoryacht are Typical 131’ Semi-Displacement Motory- seakeeping and fuel economy. of Designs Offered by Delta Marine [Delta] Eric Goetz Eric Goetz began building custom boats in Bristol, RI in 1975 working with the Gougeon Brothers WEST system. In 1995, Goetz built all of the defending America’s Cup boats using prepreg technology. Low temperature epoxy prepregs are vacuum consolidated and cured in a � portable oven. Nomexand aluminum honeycomb cores are used with this process, as are � glass, carbon and Kevlareinforcements. Of the 80 or so boats that Goetz has built, most are racing or cruising sailboats designed to go fast. He also has applied his skills at an offshore racing powerboat and some specialized military projects. Goetz believes that prepreg technology can be competitive with high-end wet lay-up methods for semi-custom yachts. Goetz Marine Technology (GMT) is a spin-off company that builds carbon fiber/epoxy masts, rudders and specialized hardware. TPI TPI is the latest boatbuilding enterprise of Everett Pearson, who built his first boat over forty years ago and has built 15,000 since. In 1959, Pearson began building the 28-foot, Carl Alberg designed Triton. This design was the first true production FRP sailboat and many are still sailing. Today, TPI builds sailboats for five different companies, including J-Boats, and manufactures windmill blades, people movers and swim spas. TPI was an early partner in the development of the SCRIMP resin infusion process. Except for their class boats, such as the J-24, all TPI’s construction utilizes this process that involves �dry� lay-up of reinforcements and infusion of resin with a closed, vacuum process. TPI makes extensive use of research & development efforts to improve materials and processes involved with construction of large composite structures for a variety of recreational and industrial applications. 7PDF Image | Marine Componsites

PDF Search Title:

Marine ComponsitesOriginal File Name Searched:

MARINE_COMPOSITES.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |