PDF Publication Title:

Text from PDF Page: 023

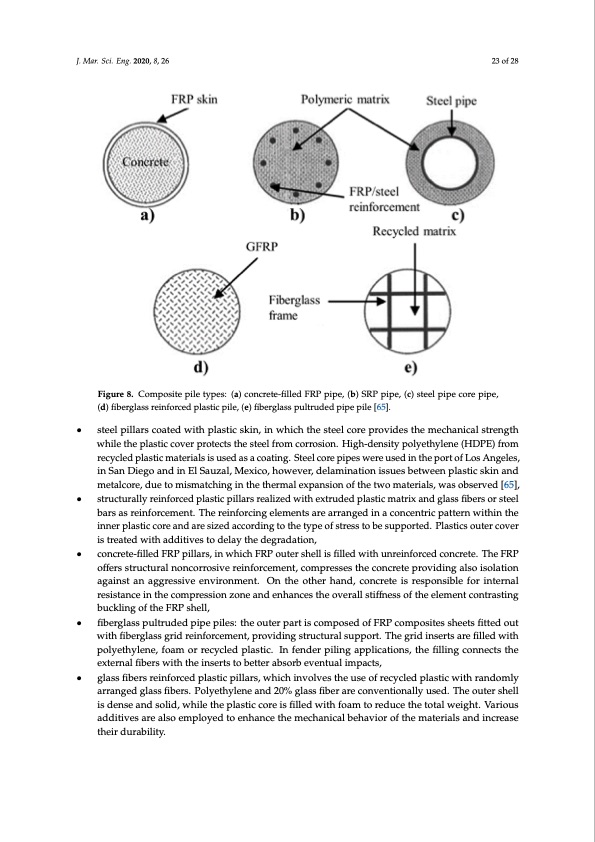

J. Mar. Sci. Eng. 2020, 8, 26 23 of 28 J. Mar. Sci. Eng. 2020, 8, x FOR PEER REVIEW 23 of 28 • • • • • Figure 8. Composite pile types: (a) concrete-filled FRP pipe, (b) SRP pipe, (c) steel pipe core pipe, Figure 8. Composite pile types: (a) concrete-filled FRP pipe, (b) SRP pipe, (c) steel pipe core pipe, (d) (d) fiberglass reinforced plastic pile, (e) fiberglass pultruded pipe pile [65]. fiberglass reinforced plastic pile, (e) fiberglass pultruded pipe pile [65]. steel pillars coated with plastic skin, in which the steel core provides the mechanical strength swteheilleptihllearpslacsotaictecdovweirthprpoltaesctiscthskeisnt,eienl fwrohmichcotrhroessiotene.lHcoigreh-pdreonvsidtyespothlyeemtheyclehnaeni(cHaDl sPtEre)nfrgotmh wrehciyleclethdeplpalsatsictimcacotevreiarlspirsoutescetdsatshaecsotaeteilngfr.oSmteeclocrorroesipoinp.esHwigehre-duesnesditiyntphoelypeotrhtyolfeLnoes(AHnDgPelEe)s, firnomSarneDcyicelgeodapnladstinicEmlaStaeurizaalsl,iMs uesxeicdoa,shaowcoeavtienr,gd. Seltaeemlicnoarteiopnipiessuweserbeeutwseedeninptlhaestpicorstkoinf Laonsd Amnegtaelceos,rein,dSuaentDoimegisomaantdchiingElinSathuezathl,eMrmexaliceox,phaonwsieovneor,fdtheelatmwionamtiaotnerisaslus,ewsabsetowbesernvpedla[s6ti5c], skin and metalcore, due to mismatching in the thermal expansion of the two materials, was structurally reinforced plastic pillars realized with extruded plastic matrix and glass fibers or steel observed [65], bars as reinforcement. The reinforcing elements are arranged in a concentric pattern within the structurally reinforced plastic pillars realized with extruded plastic matrix and glass fibers or inner plastic core and are sized according to the type of stress to be supported. Plastics outer cover steel bars as reinforcement. The reinforcing elements are arranged in a concentric pattern within is treated with additives to delay the degradation, the inner plastic core and are sized according to the type of stress to be supported. Plastics outer concrete-filled FRP pillars, in which FRP outer shell is filled with unreinforced concrete. The FRP cover is treated with additives to delay the degradation, offers structural noncorrosive reinforcement, compresses the concrete providing also isolation concrete-filled FRP pillars, in which FRP outer shell is filled with unreinforced concrete. The FRP against an aggressive environment. On the other hand, concrete is responsible for internal offers structural noncorrosive reinforcement, compresses the concrete providing also isolation resistance in the compression zone and enhances the overall stiffness of the element contrasting against an aggressive environment. On the other hand, concrete is responsible for internal buckling of the FRP shell, resistance in the compression zone and enhances the overall stiffness of the element contrasting fiberglass pultruded pipe piles: the outer part is composed of FRP composites sheets fitted out buckling of the FRP shell, with fiberglass grid reinforcement, providing structural support. The grid inserts are filled with fiberglass pultruded pipe piles: the outer part is composed of FRP composites sheets fitted out polyethylene, foam or recycled plastic. In fender piling applications, the filling connects the with fiberglass grid reinforcement, providing structural support. The grid inserts are filled with external fibers with the inserts to better absorb eventual impacts, polyethylene, foam or recycled plastic. In fender piling applications, the filling connects the glass fibers reinforced plastic pillars, which involves the use of recycled plastic with randomly external fibers with the inserts to better absorb eventual impacts, arranged glass fibers. Polyethylene and 20% glass fiber are conventionally used. The outer shell glass fibers reinforced plastic pillars, which involves the use of recycled plastic with randomly is dense and solid, while the plastic core is filled with foam to reduce the total weight. Various arranged glass fibers. Polyethylene and 20% glass fiber are conventionally used. The outer shell additives are also employed to enhance the mechanical behavior of the materials and increase is dense and solid, while the plastic core is filled with foam to reduce the total weight. Various their durability. additives are also employed to enhance the mechanical behavior of the materials and increase their durability.PDF Image | Marine Application of Fiber Reinforced Composites

PDF Search Title:

Marine Application of Fiber Reinforced CompositesOriginal File Name Searched:

jmse-08-00026.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |