PDF Publication Title:

Text from PDF Page: 019

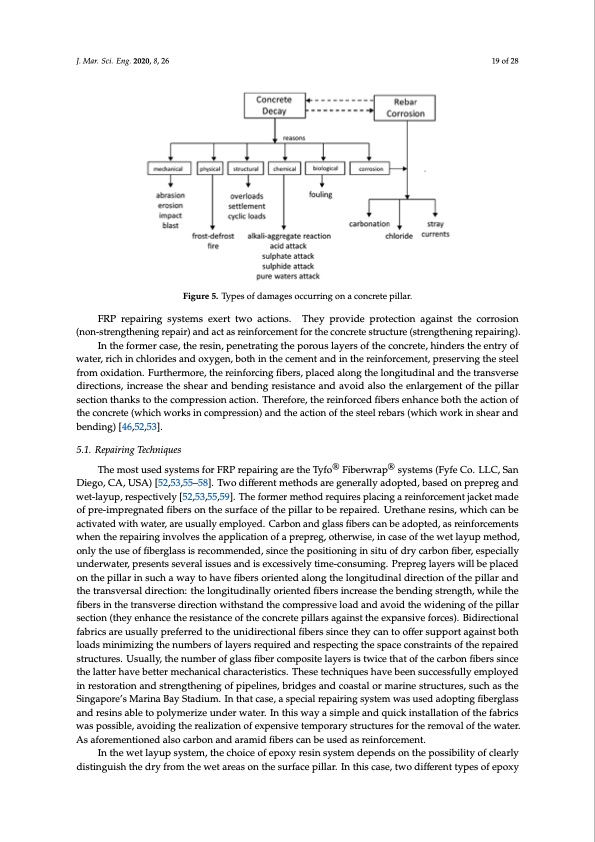

J. Mar. Sci. Eng. 2020, 8, 26 19 of 28 J. Mar. Sci. Eng. 2020, 8, x FOR PEER REVIEW 19 of 28 Figure 5. Types of damages occurring on a concrete pillar. Figure 5. Types of damages occurring on a concrete pillar. FRP repairing systems exert two actions. They provide protection against the corrosion (non-FsRtrPenrgetphaeinring rseypsateirm) asnedxearct atws roeiancftoiorcnesm. Tenhtefyorptrhoevicdoencprreotetescttriuocntuargea(isntrsetntghteheconrinrogsrieopna(irnionng-). strengInthtehneinfogrmreepracira)saen, dthaecrteassinr,epinefnoertcreamtienngttfhoer pthoerocuosnclareyterstoruf cthtuerceo(nstcrenteg,thiendinegrsrtehpeaeirnintrgy).of wateIrn,rtihcheifnorcmhleorrcidaeses,atnhdeorexsyigne,np,ebnoethraitnintghethcempoernotuasnldayinertsheofrethinefocorcnecmreetne,t,hpinredsersvitnhgetehnetrsyteoefl wfroatmero, rxicdhaitniocnh. lFourirdtheseramndoroex, ythgenre, ibnoftohrciintghfiebcerms,epnltaacned ainlotnhge trheeinlfonrgceitmudenint,apl arensdertvhientgrathnesvseterseel fdroirmectoixoindsa,tinoncr.eFausreththeermshoerea,rthanedrebinefnodricninggrfeisbiesrtas,npcleacaendaalovnogidthaelslonthgeituendlianragleamndentht eoftrtahnesvpeilrlsaer dseircetciotinonths,aninkcsretoastehethceomshperaerssainodn abcetniodnin. gThresreisftoarnec, ethaenrdeianvforicdedalsfiobethrseeennhlanrgcembeontht tohfethacetipoinllaorf stehceticoncthreatnek(wsthoicthewcormkspirnescsoimonparecstisoionn.)Tahnedretfhoerea,cthioenroeifntfhoercsetedelfirbeebrasresn(whahnichebwotrhktihnesahcetaiornanodf tbheencdoingcr)e[t4e6,(5w2h,5i3c]h. works in compression) and the action of the steel rebars (which work in shear and bending) [46,52,53]. 5.1. Repairing Techniques 5.1. Repairing Techniques ® ® The most used systems for FRP repairing are the Tyfo Fiberwrap systems (Fyfe Co. LLC, San Diego, CA, USA) [52,53,55–58]. Two different methods are ®generally ad®opted, based on prepreg and The most used systems for FRP repairing are the Tyfo Fiberwrap systems (Fyfe Co. LLC, San wet-layup, respectively [52,53,55,59]. The former method requires placing a reinforcement jacket made Diego, CA, USA) [52,53,55–58]. Two different methods are generally adopted, based on prepreg and of pre-impregnated fibers on the surface of the pillar to be repaired. Urethane resins, which can be wet-layup, respectively [52,53,55,59]. The former method requires placing a reinforcement jacket activated with water, are usually employed. Carbon and glass fibers can be adopted, as reinforcements made of pre-impregnated fibers on the surface of the pillar to be repaired. Urethane resins, which can when the repairing involves the application of a prepreg, otherwise, in case of the wet layup method, be activated with water, are usually employed. Carbon and glass fibers can be adopted, as only the use of fiberglass is recommended, since the positioning in situ of dry carbon fiber, especially reinforcements when the repairing involves the application of a prepreg, otherwise, in case of the wet underwater, presents several issues and is excessively time-consuming. Prepreg layers will be placed layup method, only the use of fiberglass is recommended, since the positioning in situ of dry carbon on the pillar in such a way to have fibers oriented along the longitudinal direction of the pillar and fiber, especially underwater, presents several issues and is excessively time-consuming. Prepreg the transversal direction: the longitudinally oriented fibers increase the bending strength, while the layers will be placed on the pillar in such a way to have fibers oriented along the longitudinal fibers in the transverse direction withstand the compressive load and avoid the widening of the pillar direction of the pillar and the transversal direction: the longitudinally oriented fibers increase the section (they enhance the resistance of the concrete pillars against the expansive forces). Bidirectional bending strength, while the fibers in the transverse direction withstand the compressive load and fabrics are usually preferred to the unidirectional fibers since they can to offer support against both avoid the widening of the pillar section (they enhance the resistance of the concrete pillars against loads minimizing the numbers of layers required and respecting the space constraints of the repaired the expansive forces). Bidirectional fabrics are usually preferred to the unidirectional fibers since they structures. Usually, the number of glass fiber composite layers is twice that of the carbon fibers since can to offer support against both loads minimizing the numbers of layers required and respecting the the latter have better mechanical characteristics. These techniques have been successfully employed space constraints of the repaired structures. Usually, the number of glass fiber composite layers is in restoration and strengthening of pipelines, bridges and coastal or marine structures, such as the twice that of the carbon fibers since the latter have better mechanical characteristics. These techniques Singapore’s Marina Bay Stadium. In that case, a special repairing system was used adopting fiberglass have been successfully employed in restoration and strengthening of pipelines, bridges and coastal and resins able to polymerize under water. In this way a simple and quick installation of the fabrics or marine structures, such as the Singapore's Marina Bay Stadium. In that case, a special repairing was possible, avoiding the realization of expensive temporary structures for the removal of the water. system was used adopting fiberglass and resins able to polymerize under water. In this way a simple As aforementioned also carbon and aramid fibers can be used as reinforcement. and quick installation of the fabrics was possible, avoiding the realization of expensive temporary In the wet layup system, the choice of epoxy resin system depends on the possibility of clearly structures for the removal of the water. As aforementioned also carbon and aramid fibers can be used distinguish the dry from the wet areas on the surface pillar. In this case, two different types of epoxy as reinforcement.PDF Image | Marine Application of Fiber Reinforced Composites

PDF Search Title:

Marine Application of Fiber Reinforced CompositesOriginal File Name Searched:

jmse-08-00026.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |