PDF Publication Title:

Text from PDF Page: 008

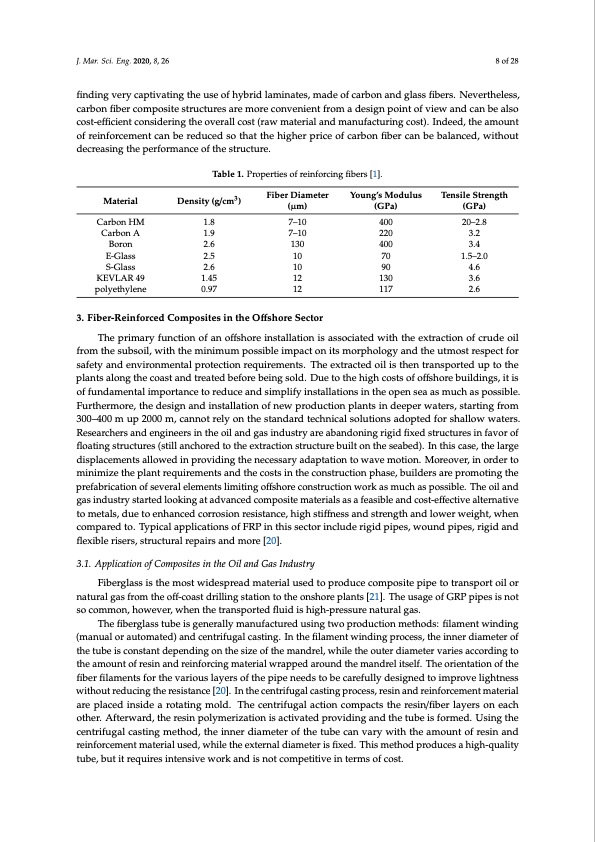

J. Mar. Sci. Eng. 2020, 8, 26 8 of 28 finding very captivating the use of hybrid laminates, made of carbon and glass fibers. Nevertheless, carbon fiber composite structures are more convenient from a design point of view and can be also cost-efficient considering the overall cost (raw material and manufacturing cost). Indeed, the amount of reinforcement can be reduced so that the higher price of carbon fiber can be balanced, without decreasing the performance of the structure. Material Carbon HM Carbon A Boron E-Glass S-Glass KEVLAR 49 polyethylene Density (g/cm3) 1.8 1.9 2.6 2.5 2.6 1.45 0.97 Fiber Diameter (μm) 7–10 7–10 130 10 10 12 12 Young’s Modulus (GPa) 400 220 400 70 90 130 117 Tensile Strength (GPa) 20–2.8 3.2 3.4 1.5–2.0 4.6 3.6 2.6 Table 1. Properties of reinforcing fibers [1]. 3. Fiber-Reinforced Composites in the Offshore Sector The primary function of an offshore installation is associated with the extraction of crude oil from the subsoil, with the minimum possible impact on its morphology and the utmost respect for safety and environmental protection requirements. The extracted oil is then transported up to the plants along the coast and treated before being sold. Due to the high costs of offshore buildings, it is of fundamental importance to reduce and simplify installations in the open sea as much as possible. Furthermore, the design and installation of new production plants in deeper waters, starting from 300–400 m up 2000 m, cannot rely on the standard technical solutions adopted for shallow waters. Researchers and engineers in the oil and gas industry are abandoning rigid fixed structures in favor of floating structures (still anchored to the extraction structure built on the seabed). In this case, the large displacements allowed in providing the necessary adaptation to wave motion. Moreover, in order to minimize the plant requirements and the costs in the construction phase, builders are promoting the prefabrication of several elements limiting offshore construction work as much as possible. The oil and gas industry started looking at advanced composite materials as a feasible and cost-effective alternative to metals, due to enhanced corrosion resistance, high stiffness and strength and lower weight, when compared to. Typical applications of FRP in this sector include rigid pipes, wound pipes, rigid and flexible risers, structural repairs and more [20]. 3.1. Application of Composites in the Oil and Gas Industry Fiberglass is the most widespread material used to produce composite pipe to transport oil or natural gas from the off-coast drilling station to the onshore plants [21]. The usage of GRP pipes is not so common, however, when the transported fluid is high-pressure natural gas. The fiberglass tube is generally manufactured using two production methods: filament winding (manual or automated) and centrifugal casting. In the filament winding process, the inner diameter of the tube is constant depending on the size of the mandrel, while the outer diameter varies according to the amount of resin and reinforcing material wrapped around the mandrel itself. The orientation of the fiber filaments for the various layers of the pipe needs to be carefully designed to improve lightness without reducing the resistance [20]. In the centrifugal casting process, resin and reinforcement material are placed inside a rotating mold. The centrifugal action compacts the resin/fiber layers on each other. Afterward, the resin polymerization is activated providing and the tube is formed. Using the centrifugal casting method, the inner diameter of the tube can vary with the amount of resin and reinforcement material used, while the external diameter is fixed. This method produces a high-quality tube, but it requires intensive work and is not competitive in terms of cost.PDF Image | Marine Application of Fiber Reinforced Composites

PDF Search Title:

Marine Application of Fiber Reinforced CompositesOriginal File Name Searched:

jmse-08-00026.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |