PDF Publication Title:

Text from PDF Page: 003

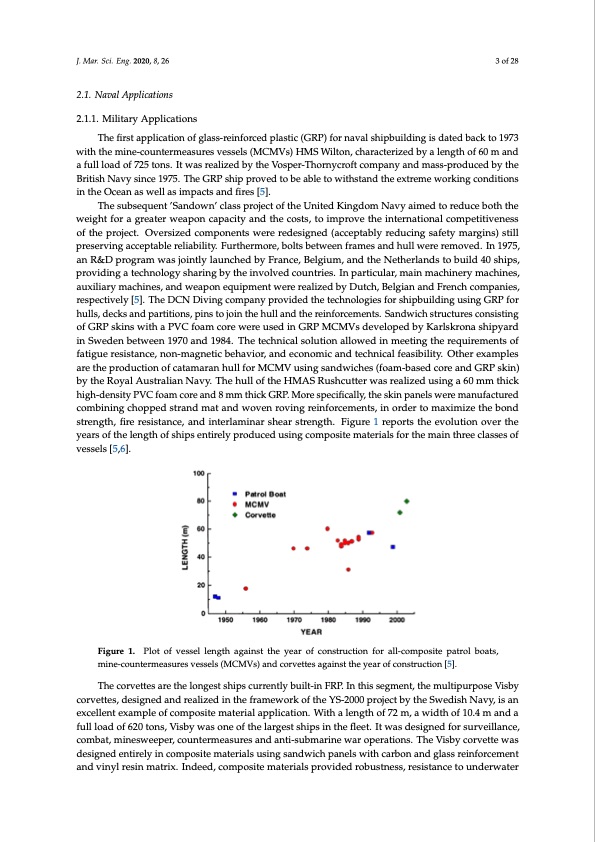

J. Mar. Sci. Eng. 2020, 8, 26 3 of 28 2.1. Naval Applications 2.1.1. Military Applications The first application of glass-reinforced plastic (GRP) for naval shipbuilding is dated back to 1973 with the mine-countermeasures vessels (MCMVs) HMS Wilton, characterized by a length of 60 m and a full load of 725 tons. It was realized by the Vosper-Thornycroft company and mass-produced by the British Navy since 1975. The GRP ship proved to be able to withstand the extreme working conditions J. Mar. Sci. Eng. 2020, 8, x FOR PEER REVIEW 3 of 28 in the Ocean as well as impacts and fires [5]. Thesubseq2.1u.eNnavtal’SAappnlidcaotiownsn’classprojectoftheUnitedKingdomNavyaimedtoreduceboththe weight for a greater weapon capacity and the costs, to improve the international competitiveness 2.1.1. Military Applications of the project. Oversized components were redesigned (acceptably reducing safety margins) still The first application of glass-reinforced plastic (GRP) for naval shipbuilding is dated back to preserving acce1p97t3awbilteh trheelmiaibnei-lciotuyn.teFrumreathsuerersmveossrels, (bMoClMtsVbs)eHtwMSeeWniltforna, cmhaerasctaenrizdedhbuylallwengetrheofre60moved. In 1975, m and a full load of 725 tons. It was realized by the Vosper-Thornycroft company and mass-produced an R&D program was jointly launched by France, Belgium, and the Netherlands to build 40 ships, by the British Navy since 1975. The GRP ship proved to be able to withstand the extreme working providing a technology sharing by the involved countries. In particular, main machinery machines, conditions in the Ocean as well as impacts and fires [5]. The subsequent 'Sandown' class project of the United Kingdom Navy aimed to reduce both the auxiliary machines, and weapon equipment were realized by Dutch, Belgian and French companies, weight for a greater weapon capacity and the costs, to improve the international competitiveness of respectively [5]. The DCN Diving company provided the technologies for shipbuilding using GRP for the project. Oversized components were redesigned (acceptably reducing safety margins) still hulls,decksandprpesaervtintgioanccsep,tpabinlesretloiabjioliityn.Ftuhrethherumlolrea,nbodltsthbetwreeinfroamrceesmandenhutlsl.wSeraenredmwoviecdh.Isnt1r9u75c,turesconsisting an R&D program was jointly launched by France, Belgium, and the Netherlands to build 40 ships, of GRP skins with a PVC foam core were used in GRP MCMVs developed by Karlskrona shipyard providing a technology sharing by the involved countries. In particular, main machinery machines, in Sweden betwauexielinary1m9a7c0hinaens,dan1d9w8e4ap.oTn ehqeuiptemcehntnwiecraelresaolizluedtbioynDuatclhlo, BwelgeidaniandmFrenecthincogmpthaneiesr,equirements of respectively [5]. The DCN Diving company provided the technologies for shipbuilding using GRP fatigue resistance, non-magnetic behavior, and economic and technical feasibility. Other examples for hulls, decks and partitions, pins to join the hull and the reinforcements. Sandwich structures are the production of catamaran hull for MCMV using sandwiches (foam-based core and GRP skin) consisting of GRP skins with a PVC foam core were used in GRP MCMVs developed by Karlskrona shipyard in Sweden between 1970 and 1984. The technical solution allowed in meeting the by the Royal Australian Navy. The hull of the HMAS Rushcutter was realized using a 60 mm thick requirements of fatigue resistance, non-magnetic behavior, and economic and technical feasibility. high-density PVC foam core and 8 mm thick GRP. More specifically, the skin panels were manufactured Other examples are the production of catamaran hull for MCMV using sandwiches (foam-based core combining choapnpdeGdRPsstkrina)nbdy thmeaRotyalnAduswtraoliavneNnavryo.vTihneghurlleoifnthfeoHrcMeAmSeRnusthsc,uittnerowrads reeralitzoedmusainxgimize the bond a 60 mm thick high-density PVC foam core and 8 mm thick GRP. More specifically, the skin panels strength, fire resistance, and interlaminar shear strength. Figure 1 reports the evolution over the were manufactured combining chopped strand mat and woven roving reinforcements, in order to years of the lenmgatxhimoizfestheipbsonednstirrenegltyh,pfireodreusiscteandceu, asnidngintcerolampinoarssihtearmstaretnegrtiha. lFsigfuorre 1threpomrtsaithne three classes of vessels [5,6]. evolution over the years of the length of ships entirely produced using composite materials for the main three classes of vessels [5,6]. Figure 1. Plot of vessel length against the year of construction for all-composite patrol boats, mine- Figure 1. Plot of vessel length against the year of construction for all-composite patrol boats, countermeasures vessels (MCMVs) and corvettes against the year of construction [5]. mine-countermeasures vessels (MCMVs) and corvettes against the year of construction [5]. The corvettes are the longest ships currently built-in FRP. In this segment, the multipurpose Visby corvettes, designed and realized in the framework of the YS-2000 project by the Swedish Navy, The corvettes are the longest ships currently built-in FRP. In this segment, the multipurpose Visby is an excellent example of composite material application. With a length of 72 m, a width of 10.4 m corvettes, designed and realized in the framework of the YS-2000 project by the Swedish Navy, is an excellent example of composite material application. With a length of 72 m, a width of 10.4 m and a full load of 620 tons, Visby was one of the largest ships in the fleet. It was designed for surveillance, combat, minesweeper, countermeasures and anti-submarine war operations. The Visby corvette was designed entirely in composite materials using sandwich panels with carbon and glass reinforcement and vinyl resin matrix. Indeed, composite materials provided robustness, resistance to underwaterPDF Image | Marine Application of Fiber Reinforced Composites

PDF Search Title:

Marine Application of Fiber Reinforced CompositesOriginal File Name Searched:

jmse-08-00026.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |