PDF Publication Title:

Text from PDF Page: 004

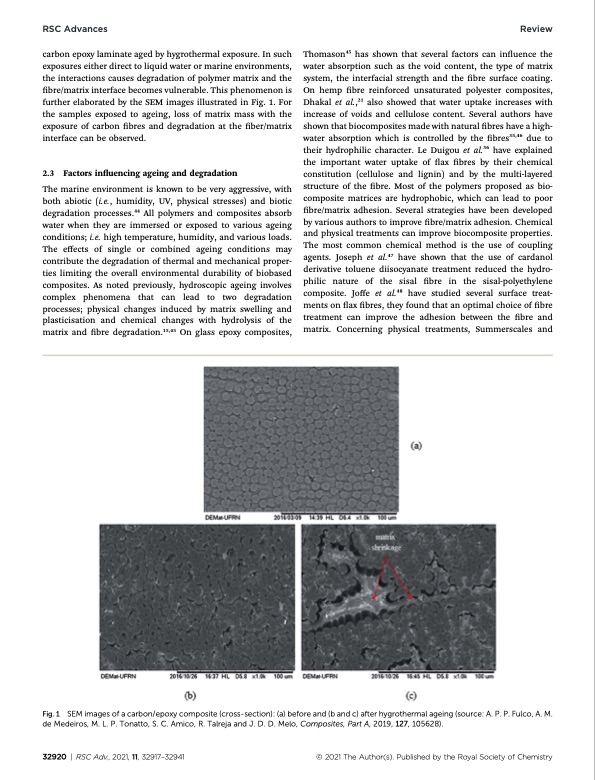

RSC Advances Review carbon epoxy laminate aged by hygrothermal exposure. In such exposures either direct to liquid water or marine environments, the interactions causes degradation of polymer matrix and the bre/matrix interface becomes vulnerable. This phenomenon is further elaborated by the SEM images illustrated in Fig. 1. For the samples exposed to ageing, loss of matrix mass with the exposure of carbon bres and degradation at the ber/matrix interface can be observed. 2.3 Factors inuencing ageing and degradation The marine environment is known to be very aggressive, with both abiotic (i.e., humidity, UV, physical stresses) and biotic degradation processes.44 All polymers and composites absorb water when they are immersed or exposed to various ageing conditions; i.e. high temperature, humidity, and various loads. The effects of single or combined ageing conditions may contribute the degradation of thermal and mechanical proper- ties limiting the overall environmental durability of biobased composites. As noted previously, hydroscopic ageing involves complex phenomena that can lead to two degradation processes; physical changes induced by matrix swelling and plasticisation and chemical changes with hydrolysis of the matrix and bre degradation.15,45 On glass epoxy composites, Thomason45 has shown that several factors can inuence the water absorption such as the void content, the type of matrix system, the interfacial strength and the bre surface coating. On hemp bre reinforced unsaturated polyester composites, Dhakal et al.,21 also showed that water uptake increases with increase of voids and cellulose content. Several authors have shown that biocomposites made with natural bres have a high- water absorption which is controlled by the bres35,46 due to their hydrophilic character. Le Duigou et al.36 have explained the important water uptake of ax bres by their chemical constitution (cellulose and lignin) and by the multi-layered structure of the bre. Most of the polymers proposed as bio- composite matrices are hydrophobic, which can lead to poor bre/matrix adhesion. Several strategies have been developed by various authors to improve bre/matrix adhesion. Chemical and physical treatments can improve biocomposite properties. The most common chemical method is the use of coupling agents. Joseph et al.47 have shown that the use of cardanol derivative toluene diisocyanate treatment reduced the hydro- philic nature of the sisal bre in the sisal-polyethylene composite. Joffe et al.48 have studied several surface treat- ments on ax bres, they found that an optimal choice of bre treatment can improve the adhesion between the bre and matrix. Concerning physical treatments, Summerscales and Fig. 1 SEM images of a carbon/epoxy composite (cross-section): (a) before and (b and c) after hygrothermal ageing (source: A. P. P. Fulco, A. M. de Medeiros, M. L. P. Tonatto, S. C. Amico, R. Talreja and J. D. D. Melo, Composites, Part A, 2019, 127, 105628). 32920 | RSC Adv., 2021, 11, 32917–32941 © 2021 The Author(s). Published by the Royal Society of ChemistryPDF Image | Long-term durability and ecotoxicity of biocomposites in marine environments

PDF Search Title:

Long-term durability and ecotoxicity of biocomposites in marine environmentsOriginal File Name Searched:

RA-011-D1RA03023J.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |