PDF Publication Title:

Text from PDF Page: 005

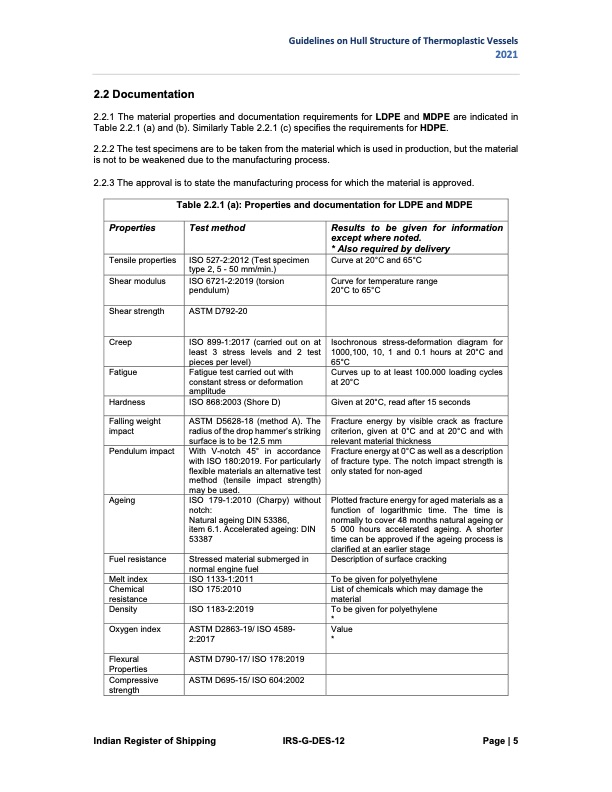

Guidelines on Hull Structure of Thermoplastic Vessels 2021 2.2 Documentation 2.2.1 The material properties and documentation requirements for LDPE and MDPE are indicated in Table 2.2.1 (a) and (b). Similarly Table 2.2.1 (c) specifies the requirements for HDPE. 2.2.2 The test specimens are to be taken from the material which is used in production, but the material is not to be weakened due to the manufacturing process. 2.2.3 The approval is to state the manufacturing process for which the material is approved. Properties Tensile properties Shear modulus Shear strength Creep Fatigue Hardness Falling weight impact Test method ISO 527-2:2012 (Test specimen type 2, 5 - 50 mm/min.) ISO 6721-2:2019 (torsion pendulum) ASTM D792-20 ISO 899-1:2017 (carried out on at least 3 stress levels and 2 test pieces per level) Fatigue test carried out with constant stress or deformation amplitude ISO 868:2003 (Shore D) ASTM D5628-18 (method A). The radius of the drop hammer’s striking surface is to be 12.5 mm Stressed material submerged in normal engine fuel ISO 1133-1:2011 ISO 175:2010 ISO 1183-2:2019 ASTM D2863-19/ ISO 4589- 2:2017 ASTM D790-17/ ISO 178:2019 ASTM D695-15/ ISO 604:2002 Results to be given for information except where noted. * Also required by delivery Curve at 20°C and 65°C Curve for temperature range 20°C to 65°C Isochronous stress-deformation diagram for 1000,100, 10, 1 and 0.1 hours at 20°C and 65°C Curves up to at least 100.000 loading cycles at 20°C Given at 20°C, read after 15 seconds Fracture energy by visible crack as fracture criterion, given at 0°C and at 20°C and with relevant material thickness Description of surface cracking To be given for polyethylene List of chemicals which may damage the material To be given for polyethylene * Value * Table 2.2.1 (a): Properties and documentation for LDPE and MDPE Pendulum impact With V-notch 45° in accordance with ISO 180:2019. For particularly flexible materials an alternative test method (tensile impact strength) may be used. Fracture energy at 0°C as well as a description of fracture type. The notch impact strength is only stated for non-aged Ageing ISO 179-1:2010 (Charpy) without notch: Natural ageing DIN 53386, item 6.1. Accelerated ageing: DIN 53387 Plotted fracture energy for aged materials as a function of logarithmic time. The time is normally to cover 48 months natural ageing or 5 000 hours accelerated ageing. A shorter time can be approved if the ageing process is clarified at an earlier stage Fuel resistance Melt index Chemical resistance Density Oxygen index Flexural Properties Compressive strength Indian Register of Shipping IRS-G-DES-12 Page | 5PDF Image | Hull Structure of Thermoplastic Vessels 2021

PDF Search Title:

Hull Structure of Thermoplastic Vessels 2021Original File Name Searched:

guidelines-on-thermoplastic-boats.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |