PDF Publication Title:

Text from PDF Page: 008

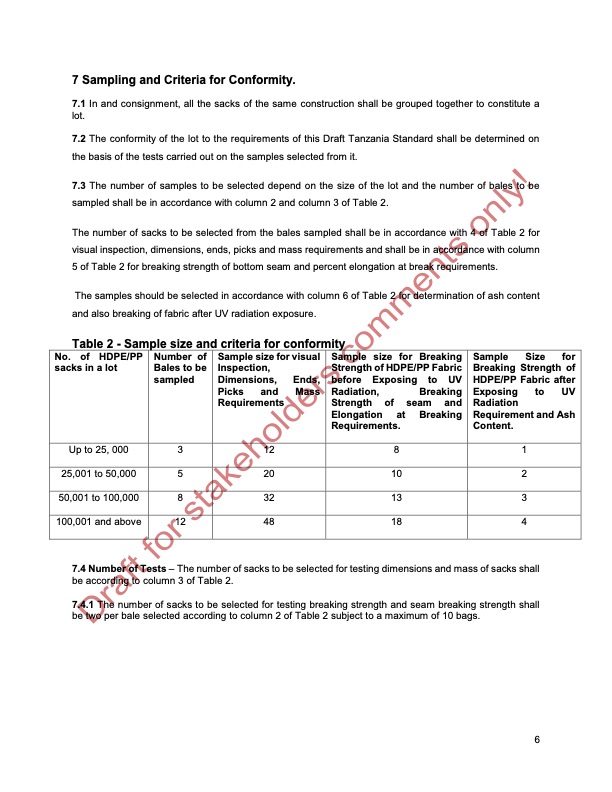

7 Sampling and Criteria for Conformity. 7.1 In and consignment, all the sacks of the same construction shall be grouped together to constitute a lot. 7.2 The conformity of the lot to the requirements of this Draft Tanzania Standard shall be determined on the basis of the tests carried out on the samples selected from it. 7.3 The number of samples to be selected depend on the size of the lot and the number of bales to be sampled shall be in accordance with column 2 and column 3 of Table 2. The number of sacks to be selected from the bales sampled shall be in accordance with 4 of Table 2 for visual inspection, dimensions, ends, picks and mass requirements and shall be in accordance with column 5 of Table 2 for breaking strength of bottom seam and percent elongation at break requirements. The samples should be selected in accordance with column 6 of Table 2 for determination of ash content and also breaking of fabric after UV radiation exposure. Table 2 - Sample size and criteria for conformity Up to 25, 000 3 12 8 1 25,001 to 50,000 5 20 10 2 50,001 to 100,000 8 32 13 3 100,001 and above 12 48 18 4 7.4 Number of Tests – The number of sacks to be selected for testing dimensions and mass of sacks shall be according to column 3 of Table 2. 7.4.1 The number of sacks to be selected for testing breaking strength and seam breaking strength shall be two per bale selected according to column 2 of Table 2 subject to a maximum of 10 bags. No. of HDPE/PP sacks in a lot Number of Bales to be sampled Sample size for visual Inspection, Dimensions, Ends, Picks and Mass Requirements Sample size for Breaking Strength of HDPE/PP Fabric before Exposing to UV Radiation, Breaking Strength of seam and Elongation at Breaking Requirements. Sample Size for Breaking Strength of HDPE/PP Fabric after Exposing to UV Radiation Requirement and Ash Content. 6PDF Image | High Density Polyethylene HDPE Polypropylene PP Woven Sacks

PDF Search Title:

High Density Polyethylene HDPE Polypropylene PP Woven SacksOriginal File Name Searched:

19_1942_00_e.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |