PDF Publication Title:

Text from PDF Page: 006

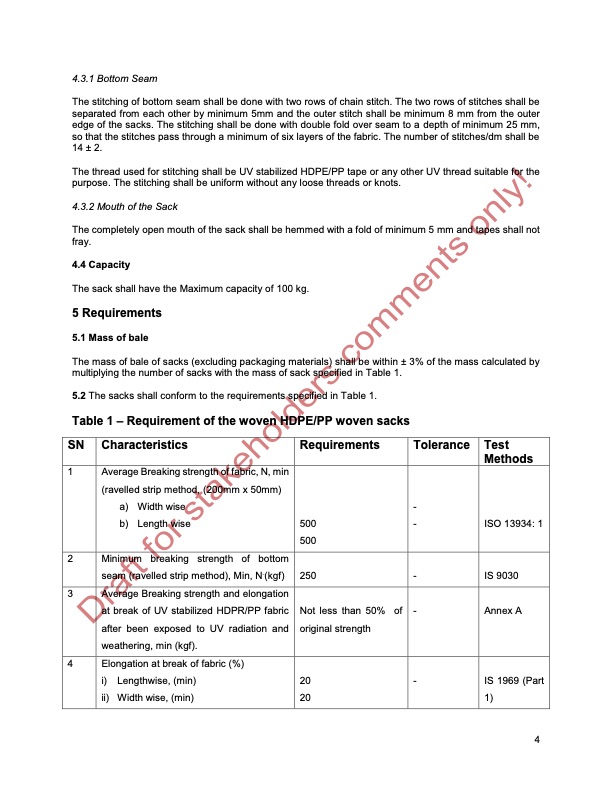

4.3.1 Bottom Seam The stitching of bottom seam shall be done with two rows of chain stitch. The two rows of stitches shall be separated from each other by minimum 5mm and the outer stitch shall be minimum 8 mm from the outer edge of the sacks. The stitching shall be done with double fold over seam to a depth of minimum 25 mm, so that the stitches pass through a minimum of six layers of the fabric. The number of stitches/dm shall be 14 ± 2. The thread used for stitching shall be UV stabilized HDPE/PP tape or any other UV thread suitable for the purpose. The stitching shall be uniform without any loose threads or knots. 4.3.2 Mouth of the Sack The completely open mouth of the sack shall be hemmed with a fold of minimum 5 mm and tapes shall not fray. 4.4 Capacity The sack shall have the Maximum capacity of 100 kg. 5 Requirements 5.1 Mass of bale The mass of bale of sacks (excluding packaging materials) shall be within ± 3% of the mass calculated by multiplying the number of sacks with the mass of sack specified in Table 1. 5.2 The sacks shall conform to the requirements specified in Table 1. Table 1 – Requirement of the woven HDPE/PP woven sacks SN Characteristics Requirements Tolerance 2 Minimum breaking strength of bottom seam (ravelled strip method), Min, N (kgf) 250 - Test Methods IS 9030 1 Average Breaking strength of fabric, N, min (ravelled strip method, (200mm x 50mm) a) Width wise b) Length wise 500 500 - - ISO 13934: 1 3 Average Breaking strength and elongation at break of UV stabilized HDPR/PP fabric after been exposed to UV radiation and weathering, min (kgf). Not less than 50% of original strength - Annex A 4 Elongation at break of fabric (%) i) Lengthwise, (min) ii) Width wise, (min) 20 20 - IS 1969 (Part 1) 4PDF Image | High Density Polyethylene HDPE Polypropylene PP Woven Sacks

PDF Search Title:

High Density Polyethylene HDPE Polypropylene PP Woven SacksOriginal File Name Searched:

19_1942_00_e.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |