PDF Publication Title:

Text from PDF Page: 015

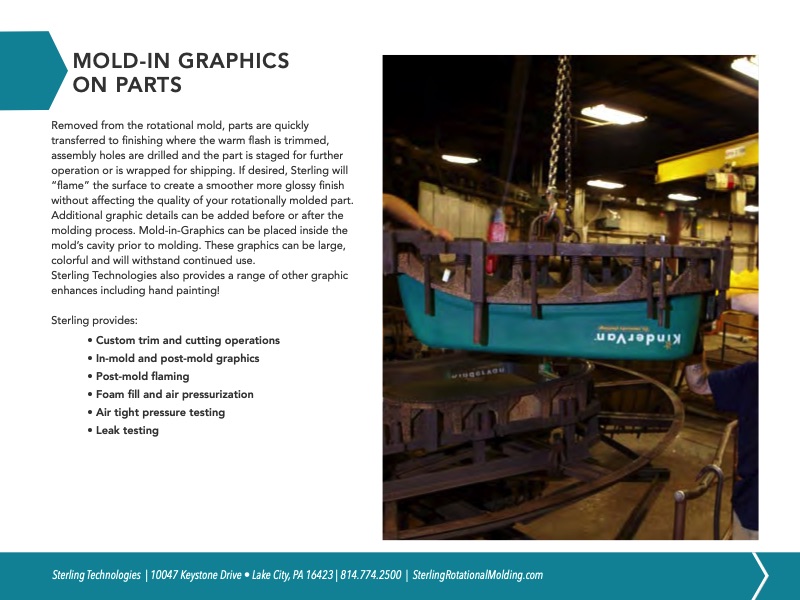

MOLD-IN GRAPHICS ON PARTS Removed from the rotational mold, parts are quickly transferred to finishing where the warm flash is trimmed, assembly holes are drilled and the part is staged for further operation or is wrapped for shipping. If desired, Sterling will “flame” the surface to create a smoother more glossy finish without affecting the quality of your rotationally molded part. Additional graphic details can be added before or after the molding process. Mold-in-Graphics can be placed inside the mold’s cavity prior to molding. These graphics can be large, colorful and will withstand continued use. Sterling Technologies also provides a range of other graphic enhances including hand painting! Sterling provides: • Custom trim and cutting operations • In-mold and post-mold graphics • Post-mold flaming • Foam fill and air pressurization • Air tight pressure testing • Leak testing Sterling Technologies | 10047 Keystone Drive • Lake City, PA 16423 | 814.774.2500 | SterlingRotationalMolding.comPDF Image | GUIDE TO PLASTIC ROTATIONAL MOLDING

PDF Search Title:

GUIDE TO PLASTIC ROTATIONAL MOLDINGOriginal File Name Searched:

GuideToPlasticRotationalMolding.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |