PDF Publication Title:

Text from PDF Page: 010

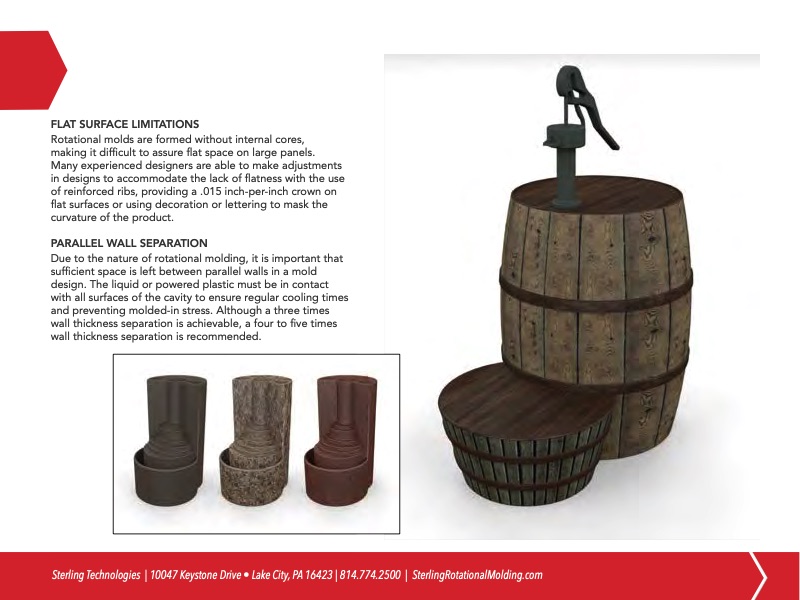

FLAT SURFACE LIMITATIONS Rotational molds are formed without internal cores, making it difficult to assure flat space on large panels. Many experienced designers are able to make adjustments in designs to accommodate the lack of flatness with the use of reinforced ribs, providing a .015 inch-per-inch crown on flat surfaces or using decoration or lettering to mask the curvature of the product. PARALLEL WALL SEPARATION Due to the nature of rotational molding, it is important that sufficient space is left between parallel walls in a mold design. The liquid or powered plastic must be in contact with all surfaces of the cavity to ensure regular cooling times and preventing molded-in stress. Although a three times wall thickness separation is achievable, a four to five times wall thickness separation is recommended. Sterling Technologies | 10047 Keystone Drive • Lake City, PA 16423 | 814.774.2500 | SterlingRotationalMolding.comPDF Image | GUIDE TO PLASTIC ROTATIONAL MOLDING

PDF Search Title:

GUIDE TO PLASTIC ROTATIONAL MOLDINGOriginal File Name Searched:

GuideToPlasticRotationalMolding.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |