PDF Publication Title:

Text from PDF Page: 027

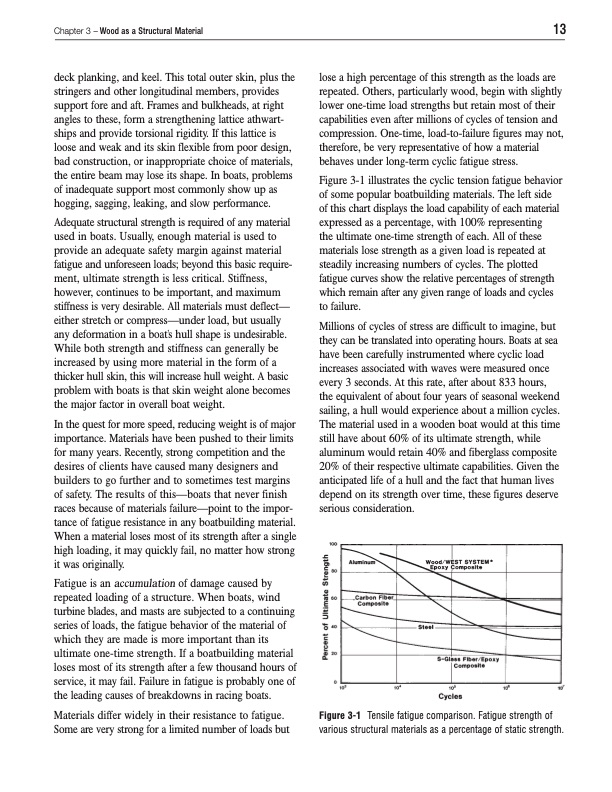

Chapter 3 – Wood as a Structural Material 13 deck planking, and keel. This total outer skin, plus the stringers and other longitudinal members, provides support fore and aft. Frames and bulkheads, at right angles to these, form a strengthening lattice athwart- ships and provide torsional rigidity. If this lattice is loose and weak and its skin flexible from poor design, bad construction, or inappropriate choice of materials, the entire beam may lose its shape. In boats, problems of inadequate support most commonly show up as hogging, sagging, leaking, and slow performance. Adequate structural strength is required of any material used in boats. Usually, enough material is used to provide an adequate safety margin against material fatigue and unforeseen loads; beyond this basic require- ment, ultimate strength is less critical. Stiffness, however, continues to be important, and maximum stiffness is very desirable. All materials must deflect— either stretch or compress—under load, but usually any deformation in a boat’s hull shape is undesirable. While both strength and stiffness can generally be increased by using more material in the form of a thicker hull skin, this will increase hull weight. A basic problem with boats is that skin weight alone becomes the major factor in overall boat weight. In the quest for more speed, reducing weight is of major importance. Materials have been pushed to their limits for many years. Recently, strong competition and the desires of clients have caused many designers and builders to go further and to sometimes test margins of safety. The results of this—boats that never finish races because of materials failure—point to the impor- tance of fatigue resistance in any boatbuilding material. When a material loses most of its strength after a single high loading, it may quickly fail, no matter how strong it was originally. Fatigue is an accumulation of damage caused by repeated loading of a structure. When boats, wind turbine blades, and masts are subjected to a continuing series of loads, the fatigue behavior of the material of which they are made is more important than its ultimate one-time strength. If a boatbuilding material loses most of its strength after a few thousand hours of service, it may fail. Failure in fatigue is probably one of the leading causes of breakdowns in racing boats. Materials differ widely in their resistance to fatigue. Some are very strong for a limited number of loads but lose a high percentage of this strength as the loads are repeated. Others, particularly wood, begin with slightly lower one-time load strengths but retain most of their capabilities even after millions of cycles of tension and compression. One-time, load-to-failure figures may not, therefore, be very representative of how a material behaves under long-term cyclic fatigue stress. Figure 3-1 illustrates the cyclic tension fatigue behavior of some popular boatbuilding materials. The left side of this chart displays the load capability of each material expressed as a percentage, with 100% representing the ultimate one-time strength of each. All of these materials lose strength as a given load is repeated at steadily increasing numbers of cycles. The plotted fatigue curves show the relative percentages of strength which remain after any given range of loads and cycles to failure. Millions of cycles of stress are difficult to imagine, but they can be translated into operating hours. Boats at sea have been carefully instrumented where cyclic load increases associated with waves were measured once every 3 seconds. At this rate, after about 833 hours, the equivalent of about four years of seasonal weekend sailing, a hull would experience about a million cycles. The material used in a wooden boat would at this time still have about 60% of its ultimate strength, while aluminum would retain 40% and fiberglass composite 20% of their respective ultimate capabilities. Given the anticipated life of a hull and the fact that human lives depend on its strength over time, these figures deserve serious consideration. Tensile fatigue comparison. Fatigue strength of various structural materials as a percentage of static strength. Figure 3-1PDF Image | Gougeon Brothers on Boat Construction

PDF Search Title:

Gougeon Brothers on Boat ConstructionOriginal File Name Searched:

GougeonBook-061205-1.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |