PDF Publication Title:

Text from PDF Page: 022

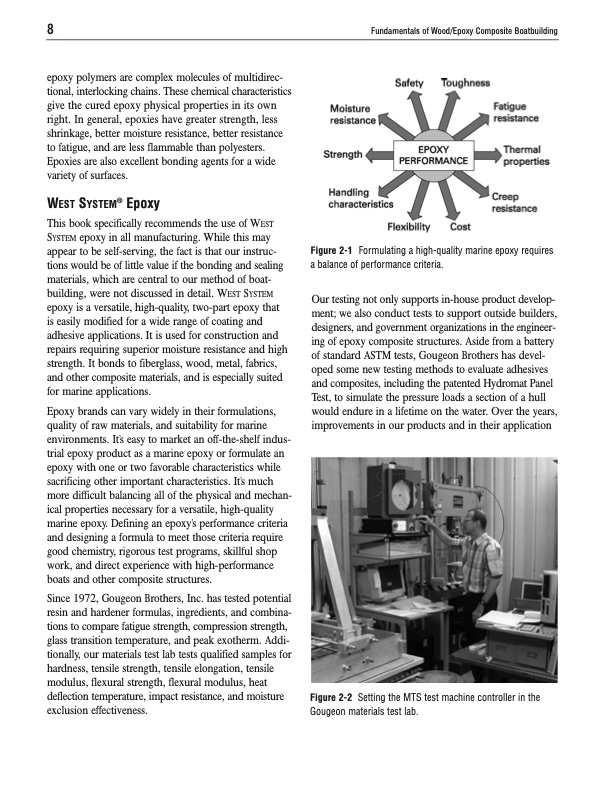

8 Fundamentals of Wood/Epoxy Composite Boatbuilding epoxy polymers are complex molecules of multidirec- tional, interlocking chains. These chemical characteristics give the cured epoxy physical properties in its own right. In general, epoxies have greater strength, less shrinkage, better moisture resistance, better resistance to fatigue, and are less flammable than polyesters. Epoxies are also excellent bonding agents for a wide variety of surfaces. WEST SYSTEM® Epoxy This book specifically recommends the use of WEST SYSTEM epoxy in all manufacturing. While this may appear to be self-serving, the fact is that our instruc- tions would be of little value if the bonding and sealing materials, which are central to our method of boat- building, were not discussed in detail. WEST SYSTEM epoxy is a versatile, high-quality, two-part epoxy that is easily modified for a wide range of coating and adhesive applications. It is used for construction and repairs requiring superior moisture resistance and high strength. It bonds to fiberglass, wood, metal, fabrics, and other composite materials, and is especially suited for marine applications. Epoxy brands can vary widely in their formulations, quality of raw materials, and suitability for marine environments. It’s easy to market an off-the-shelf indus- trial epoxy product as a marine epoxy or formulate an epoxy with one or two favorable characteristics while sacrificing other important characteristics. It’s much more difficult balancing all of the physical and mechan- ical properties necessary for a versatile, high-quality marine epoxy. Defining an epoxy’s performance criteria and designing a formula to meet those criteria require good chemistry, rigorous test programs, skillful shop work, and direct experience with high-performance boats and other composite structures. Since 1972, Gougeon Brothers, Inc. has tested potential resin and hardener formulas, ingredients, and combina- tions to compare fatigue strength, compression strength, glass transition temperature, and peak exotherm. Addi- tionally, our materials test lab tests qualified samples for hardness, tensile strength, tensile elongation, tensile modulus, flexural strength, flexural modulus, heat deflection temperature, impact resistance, and moisture exclusion effectiveness. Figure2-1 Formulatingahigh-qualitymarineepoxyrequires a balance of performance criteria. Our testing not only supports in-house product develop- ment; we also conduct tests to support outside builders, designers, and government organizations in the engineer- ing of epoxy composite structures. Aside from a battery of standard ASTM tests, Gougeon Brothers has devel- oped some new testing methods to evaluate adhesives and composites, including the patented Hydromat Panel Test, to simulate the pressure loads a section of a hull would endure in a lifetime on the water. Over the years, improvements in our products and in their application Figure 2-2 Setting the MTS test machine controller in the Gougeon materials test lab.PDF Image | Gougeon Brothers on Boat Construction

PDF Search Title:

Gougeon Brothers on Boat ConstructionOriginal File Name Searched:

GougeonBook-061205-1.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |