PDF Publication Title:

Text from PDF Page: 013

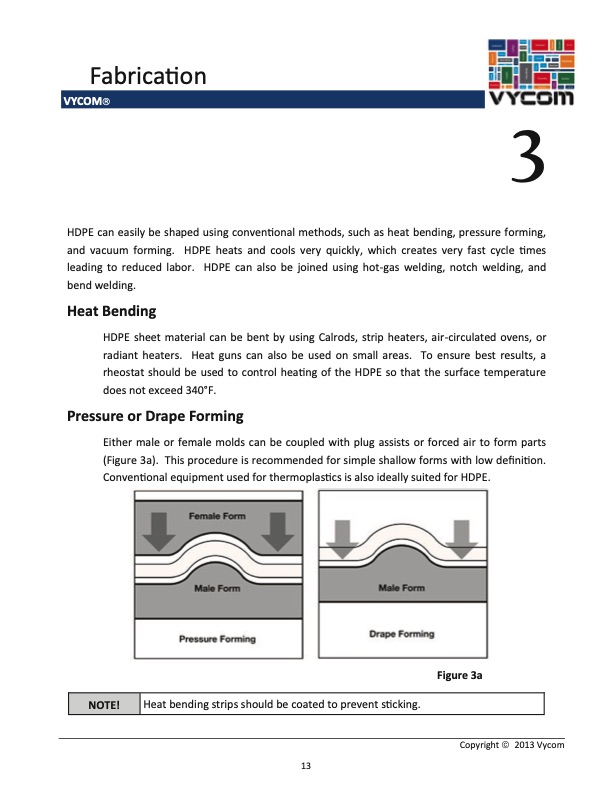

Fabrication VYCOM HDPE can easily be shaped using conventional methods, such as heat bending, pressure forming, and vacuum forming. HDPE heats and cools very quickly, which creates very fast cycle times leading to reduced labor. HDPE can also be joined using hot-gas welding, notch welding, and bend welding. Heat Bending HDPE sheet material can be bent by using Calrods, strip heaters, air-circulated ovens, or radiant heaters. Heat guns can also be used on small areas. To ensure best results, a rheostat should be used to control heating of the HDPE so that the surface temperature does not exceed 340°F. Pressure or Drape Forming Either male or female molds can be coupled with plug assists or forced air to form parts (Figure 3a). This procedure is recommended for simple shallow forms with low definition. Conventional equipment used for thermoplastics is also ideally suited for HDPE. 3 Figure 3a NOTE! Heat bending strips should be coated to prevent sticking. Copyright 2013 Vycom 13PDF Image | FABRICATION MANUAL HDPE

PDF Search Title:

FABRICATION MANUAL HDPEOriginal File Name Searched:

HDPE Fabrication Guide.pdfDIY PDF Search: Google It | Yahoo | Bing

Development of a solar powered Electric Ship The Electricship website originally started off as a project to develop a comprehensive renewable, affordable, modular electric ship... More Info

Modular Boat Hull Composite The case for a unsinkable, modular composite hybrid boat hull... More Info

MS Burgenstock Hybrid Electric Catamaran Lake Lucerne Unique shuttle servicing Lucerne to the Burgenstock Resort... More Info

Ground Power Unit GPU Powered by Lithium Ion Batteries The goal of the Ground Power Unit is to provide a readily accessible, modular, ready-to-power solution for remote power... More Info

| CONTACT TEL: 608-238-6001 Email: greg@electricship.com | RSS | AMP |